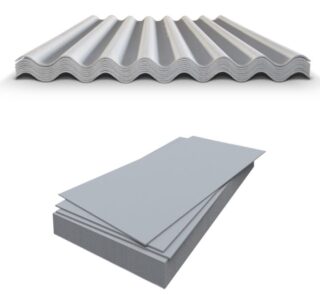

Slate is a material used in roofing, which is flat or corrugated sheets of asbestos cement. The shaped product is marketed in different designs. In view of this, when choosing, one should take into account the composition and manufacturing technology. This will allow you to build a reliable and safe structure.

Historical reference

Wave slate was invented in 1902 by an engineer from Australia L. Gatchek... Its development made it possible to establish the production of roofing material on a large scale. Gradually, the product began to be produced in France, Italy and the Czech Republic. Since 1908, this material began to be made in tsarist Russia.

The first plant for the production of slate was built in a small the village of Fokino, Bryansk region... Since the largest mineral reserves are located in Russia, the material has gained wide popularity as a roof arrangement. Before the outbreak of World War II, there were about six large factories in the Soviet Union producing flat and wave slate.

Slate making procedure

The asbestos-cement grade of slate is still in high demand among roofing materials. This is primarily due to low price of the product. Products are put on the market in different waveforms - standard, reinforced, unified, there is also flat models.

Technology

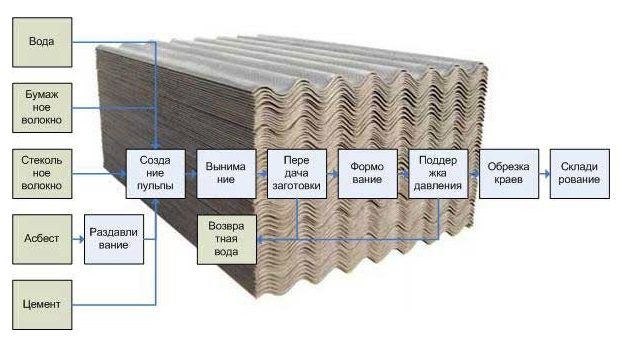

Phased production technology as follows:

- Pulp is made from chrysolite-asbestos, water, fillers, cement and fiberglass.

- The raw materials are kneaded in special containers.

- The recess has a strict dosage of the portion required to produce one sheet.

- The mixture is given the desired shape, followed by the extraction of part of the liquid.

- The workpiece is transferred to the equipment, where, under pressure, the remaining moisture evaporates.

- The dimensions of the products are given in accordance with GOST 30340-2012, which also includes the definition, slate, what it is and technical parameters.

- Scraps and small pieces are sent for recycling.

Finished products are transferred to storage for curing. After testing a sample of the batch, the goods are sent to the customer or to the store counter.

Summer residents create high beds from roofing slate.

Slate shapes

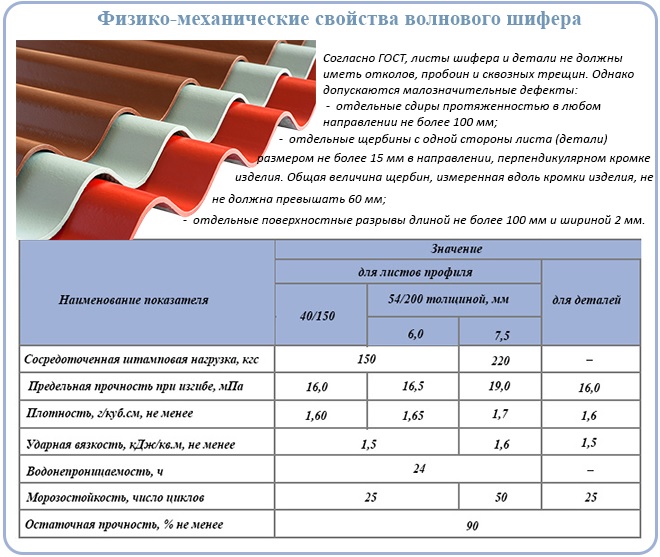

The construction industry offers consumers different types of materials based on their functional purpose. The difference between slate grades depends on the thickness and shape:

- wave;

- flat.

Any of these options can be used to equip roofs, partitions, fences or gazebos. This material is chosen not only for its beauty, but also for the reliability of the finished structure. Products possess bending strength from 18 to 23 MPa.

Products delivered to stores in roll or sheets... The first option is soft, since it contains minfibre with bitumen impregnation. The second type is more often used in the construction of utility blocks, fences, temporary fences and partitions. Thanks to various additives, the level of harmfulness of the material is reduced.

The dimensions of a standard sheet slate are subject to GOST 30340-2012: 1125x1750 cm, thickness 0.6-0.75 mm, wave step up to 20 cm.

Slate composition

If the decision is made in favor of a functional material, it is necessary to know which type is the safest. As part of slate used different mixes to get a beautiful wave:

- Plastic - 70% homogeneous polyvinyl chloride. To add strength to the product, a fiberglass additive is used. The material does not emit toxic substances.

- Bituminous products - made from synthetic and bituminous resins, cellulose and mineral fillers. Due to the presence of natural components, the canvas is environmentally friendly.

- Fiber cement as a base mixed with cement, PVA, cellulose and limestone. It is in demand due to the absence of asbestos in the composition.

- Metal based slate is made with double-sided galvanizing, and the inner part is additionally varnished. The material produced according to the standards of GOST and TU is considered non-hazardous.

- Rubber products - a relatively new type of products in the construction market. Slate is made from rubber-fabric waste and twisted non-toxic thread.

- Stamps asbestos 85% consist of Portland cement M300, 400 and 500, as well as 15% fiber with the addition of water and chrysolite.

It is not recommended to use nails for the installation of slate, as they lead to the split of the sheet.

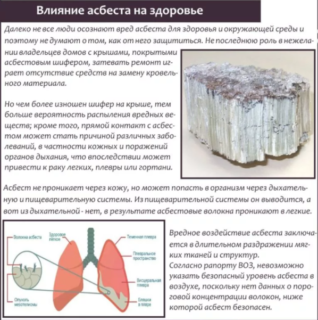

Safety of use in construction

In view of this opinions on the safety of slate differ... Some consumers claim that the material is unhealthy and can cause serious illness. Other buyers speculate that premium roofing manufacturers have created this myth.

The presence of asbestos in slate is really can provoke a negative reaction subject to ingestion. However, the fibers used in production fall into two categories - arysotile and amphibole. The amphibole slate has a harmful effect on human health. However, it is used in a mixture only in Europe in the absence of the first substance in the public domain. In this way, Russian-made roofing material is safe.