As supporting structures in construction, they often use not concrete brick structures, but a metal profile. Channel - one of the options for such rolled metal. It is made from steel of different grades and is used in a wide variety of areas.

General description and purpose of channels

Since the load in the supporting structures is often unevenly distributed, release U-shaped profile with shelves of different widths. This makes it possible to compensate for the overload and ensures the durability of the support.

The range of U-shaped profiles is characterized by high rigidity.

The structure made of channels according to GOST, has no weak points... It is very difficult to destroy it.

GOSTs

Weight, dimensions, profile configuration are regulated by GOST. Since products are manufactured for various industries, its own standard has been developed for the manufacture of each type.

- GOST 8240-97 describes the range of hot-rolled channels, both of general value - for the construction and reinforcement of floors and walls, and special.

- The profile obtained for the automotive industry is regulated by GOST 19425-74.

- Products for car building are described by GOST 5267.0-90 and 5267.1-90.

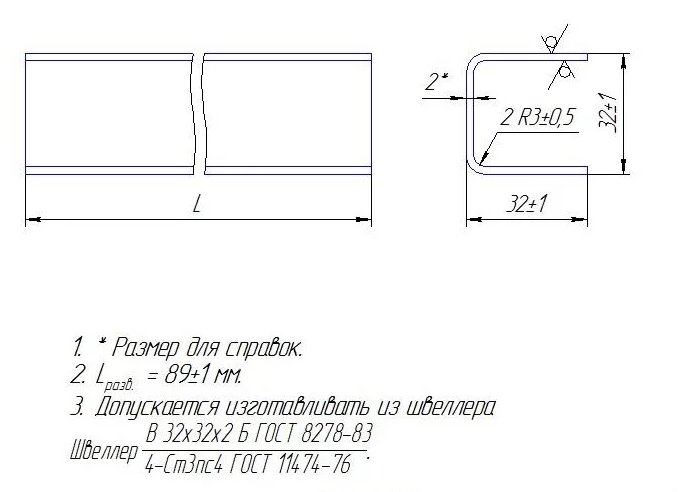

- Each of the standards describes not only the classic type of channel - equal-flange and with parallel flanges, but also wide-flange, bent, with different accuracy classes - GOST 8278-83B GOST 8281-80, GOST 5422-73.

The U-shaped profile is made of both hot-rolled and cold-rolled steel. The material for the beams must also comply with GOST.

Characteristics

When choosing a beam for construction, it is necessary to consider the following parameters:

- Configuration - Equal, with different shelf widths, with or without a slope.

- Channel dimensions and weight - it depends on these indicators what kind of load the future structure can withstand.

- Accuracy class - they produce products with a height of accuracy - category "A", increased - "B", and normal - "B". In construction, models of the usual class are used. For critical work, a profile of increased accuracy is required, with a minimum margin of error.

Steel grade is a standard characteristic and is regulated by GOST. Therefore, this parameter may not be considered separately.

Product classification and scope

Conventional hot rolled

A popular type of shaped profile. Applicable for reinforcement and stiffening of frames and other supporting structures.

Part is being made by hot rolling technology. The steel billet is heated and rolled through a rolling mill, where it is U-shaped. The weight of the channel is higher than that of the bent one, for example, the accuracy of the shapes is lower. Thick blocks of this type are quite difficult to connect, however, due to the thickness and configuration, such structures can withstand high loads. At the same time, the material consumption of the profile is lower than the solid bar. For manufacturing use alloy steel... This means that no additional restrictions need to be observed when welding channels.

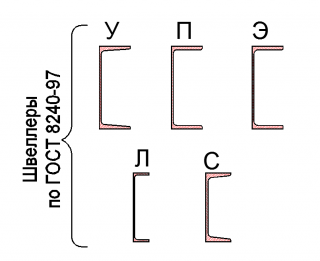

- Series P - model with parallel shelves. The most popular option. Available in lengths from 2 to 12 m, however, beams of any measured and unmeasured length are supplied on request. Products with parallel edges are the most massive. The mass of 1 running meter ranges from 4.84 to 48.28 kg.

- Series U - in this profile, the shelves are parallel to each other, if you evaluate the outer sides of the part. However, inside the shelves have a slope due to the different thickness of the edge and the place of connection with the wall. The slope is smooth, has a certain radius of curvature, which is regulated by GOST. It ranges from 6 to 15 mm. In this case, the mass of the channel with sloped shelves coincides with the analog from the P series, provided the wall thickness and dimensions are the same. The slope is small: the maximum value reaches 10%.

- Series E - economical. Received this name due to the lower material consumption. This is achieved by rounding the parallel shelves without reducing the thickness. But with these dimensions, the lightest channel of the P series weighs 4.84 kg, and that of the E series - 4.79 kg. When using rolled metal in construction work, this difference turns into big savings.

- Series L - lightweight. Version with parallel rounded shelves and reduced wall and shelf thickness. The assortment of the light model is presented in only 9 options. Compared to the P or U series, such elements withstand less stress.

- Serie C - highly specialized. Its dimensions correspond to industry requirements and are more specific. This includes, for example, a variant intended for car building. In such a profile, the upper shelf is bent and differs in width from the other by 6–10%.

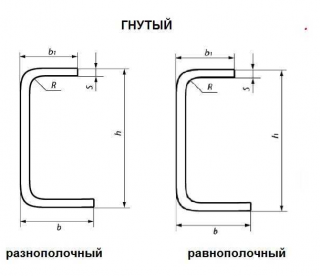

Bent

The bent channel or "correct" was named not because of the shape, but thanks to the manufacturing technology... In terms of configuration, it is somewhat different from the usual one. Parallel faces are rounded not only from the inside, but also from the outside.

For such an element, take coiled cold rolled or hot rolled steel - conventional, structural carbon and low alloy. The characteristics of the resulting profile depend on the characteristics of the raw materials. The most durable and dimensionally accurate channels are made from cold rolled carbon steel.

Produce channels on roll forming machines... The steel strip is fed to the mill, where it is cold-U-shaped.

Bent profile inferior in strength to hot-rolled... At the same time, he is noticeably surpasses it in resistance to deformation and is used to reinforce structures subjected to high tensile and compressive loads.

Distinguish 4 types of roll-formed profiles:

- IN - the edges of the shelves are inclined inward;

- P - the shelves are exactly parallel to each other;

- L - light channel with a thinner wall and parallel edges;

- FROM - a special beam.

The bent channel is produced both in accordance with GOST and in accordance with the technical specification. The dimensions of the channel can be far from the standard.

The bent steel profile is produced in standard, high and high precision. The class requirements are higher here. Deviations for increased accuracy are only 1.5 mm for shelf heights up to 15 cm.

Unequal - regulated by GOST / 82821-80. It is most often made from boiling carbon steel as it provides over 460 tensile strength. However, the channel can also be made of alloy steel, if it has the same characteristics.

The range of lengths for unequal options is the same as for equal ones. They are distinguished by the distance between the shelves, the so-called step.

Channel assortment

Despite the difference in configuration, the U-shaped profile is used in similar works and often has very similar parameters. The dimensions of the channel, for example, of the P or U series, practically coincide. The wall thickness in the L series is less, as well as the weight of the product.

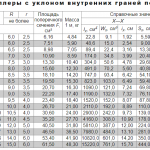

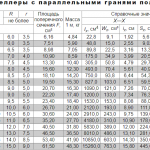

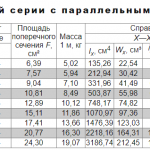

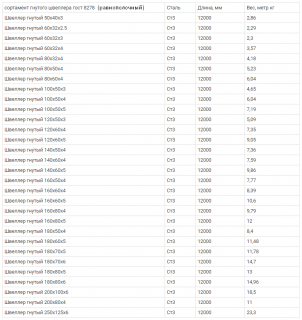

Dimensions of hot-rolled channels:

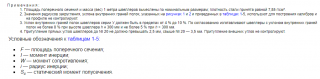

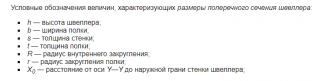

Symbols and notes:

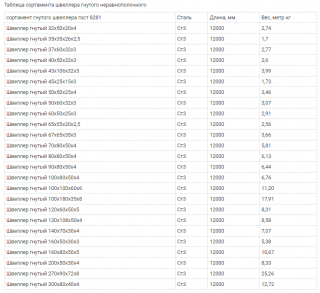

Sizes of bent channels:

Marking and decoding

Rolled metal has an alphanumeric designation reflecting the dimensions of the product, the type of steel used, and the series.

Marking begins with the word "Channel", denoting the type of metal profile, then indicates:

- the first number - indicates the height of the wall in cm;

- the next letter denotes a series - P, U, L;

- the accuracy class is put through a hyphen: B - normal, B - increased;

- a small letter "a" can be placed between the first number and the letter - it indicates that the width and thickness of the edge is increased here;

- GOST regulating products of this type.

The folded profile is marked differently:

- the first are the dimensions - the height of the wall, the width of the edge and the thickness for an equal channel channel, and the height of the wall, the thickness and width of each shelf for an unequal channel;

- the second letter denotes the accuracy class: A - high, B - increased, B - normal;

- the corresponding products are indicated by GOST;

- after the sign of the fraction, the steel grade from which the channel is made, and GOST, regulating its characteristics, are given.