SIP panels were first used for the construction of residential buildings in the late 1940s. Since then, the range of products has expanded. The modern developer needs to understand which version to choose depending on the operating conditions.

- Description of SIP technology

- Advantages and disadvantages of self-supporting insulated wire in housing construction

- Positive properties of technology

- Disadvantages of buildings

- Comparison of self-supporting insulated wire of different designs

- Construction features

- Foundations

- Tools and materials

- Building walls

- Finishing

- Frequent mistakes when building from self-supporting insulated wire

Description of SIP technology

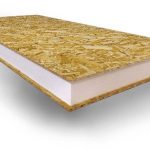

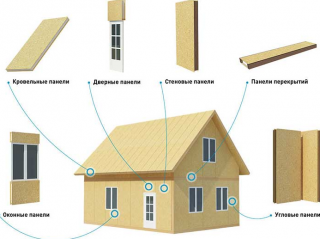

The material is a one-piece structure, in which a heat-insulating material is glued between two rigid outer panels.

Products have become widespread in which they use oriented strand board (OSB, OSB), and the insulation is foamed expanded polystyrene (foam).

In some cases, it is more advisable to use varieties of SIP panels, in the design of which the load-bearing elements are fiberboard, glass-magnesium sheet, moisture-resistant plywood, and polyurethane foam and mineral (stone) wool are insulation.

Advantages and disadvantages of self-supporting insulated wire in housing construction

Canadian SIP technology construction is considered basic for the construction of houses from KTP. The construction of the house is a symbiosis of frame and panel technologies.

SIP panels are mounted on a pre-prepared site. To fasten the elements together, a wooden beam is used, which is hidden in the grooves of the panels. By alternately installing the panel and the frame beams, they assemble a single structure.

Positive properties of technology

At home do not require additional insulation, which allows you to save on finishing materials. For example, 50 mm of polyurethane or 80 mm of polystyrene retains heat in the same way as a 1.5 meter thick brick wall. This property allows you to save useful space, since the walls take up much less space than traditional brick or blocks.

Maximum transverse load can be up to 800 kg / m³ surface, or about 3 tons per 1 sheet of standard size. In the vertical direction, one running meter can withstand up to 2.5–3 tons of load. The characteristics allow you to build multi-storey buildings and use self-supporting insulated wire for ceilings and warm roofs.

The surface of the panels is completely excludes blowing, as well as the tongue-and-groove system in the joints. If necessary, the voids are sealed with polyurethane foam.

Average 1 m² of KTP wall weighs 17–19 kg. This significantly reduces the load on the foundation, allows you to equip light, inexpensive foundations. In humid areas, a cheap pile foundation is often used, which can reliably isolate the building from water. When it is required to increase the number of storeys, use self-supporting insulated wire installed on top of the existing walls.

Soundproofing provides comfort in housing built close to busy roads.

Most of the time during the construction of houses using Canadian technology is occupied by the construction of the foundation. Further each sheet fills up to 3 m² of the wall, which allows you to far ahead of the time frame for the construction of brick or block buildings. Build a house from SIP panels on the strength of two workers... The heaviest elements weigh about 60 kg, which makes it easier to unload, transport the slab to the installation site. Fitting of parts is carried out using a hand saw and a device for sampling a groove in the insulation.

Homes are safe under normal operating conditions. The foam begins to release toxic substances only when heated above 85 ° C.

When purchasing a self-supporting insulated wire, it is important to make sure of the quality of the components. Modern OSB sheets are made with minimal use of phenol, which makes them safe in everyday life.

Through walls of small thickness into the room more direct sunlight penetrates... For the same level of illumination with stone houses, the windows themselves can be smaller. This reduces heat loss and requires less fuel for heating.

No shrinkage accelerates the beginning of the finishing process, it can be started immediately after the construction of the frame.

Disadvantages of buildings

As you age the effectiveness of flame retardant impregnation decreases OSB. Despite the characteristic of self-extinguishing (no more than 4 seconds), the foam burns under the influence of open fire, emitting toxic substances. Exposure to fire increases the cost of wiring. Hidden wiring is done in metal pipes. For laying on the surface of the walls, electrical boxes or an expensive cable are used.

Due to the fact that excess moisture in the air cannot be removed through the outer walls, they definitely suit forced exhaust ventilation all premises.

Walls do not accumulate heat - only the air is warmed up. As a result, even a short airing quickly cools the house.

Houses with OSB and plywood panels can not be left without external finishing for longer than one season... Sunlight and moisture lead to rapid deterioration, loss of positive properties of the building material.

Comparison of self-supporting insulated wire of different designs

The industry produces KTP in several versions combinations of external panels and insulation:

- expanded polystyrene (polystyrene), glued between sheets of OSB, moisture-resistant plywood, fiberboard;

- stone wool and sheets of OSB, fibrolite, glass magnesite;

- polyurethane foam and OSB, fiberboard, glass magnesite, plywood, cement particle boards.

Thermal conductivity mainly depends on the thickness of the insulation and its properties. The coefficient of thermal conductivity in a dry state is the best for polyurethane foam - 0.02, for foam - 0.039, and for mineral wool - 0.047 W / (m * deg * C). As it gets wet, the indicator deteriorates for each material.

According to the norms of SNiP for the Moscow region, it is enough insulation thickness:

- polyurethane foam - 61 mm;

- foam - 122 mm;

- mineral wool - 143 mm.

Resistance to external influences is primarily due to the material of the outer walls.

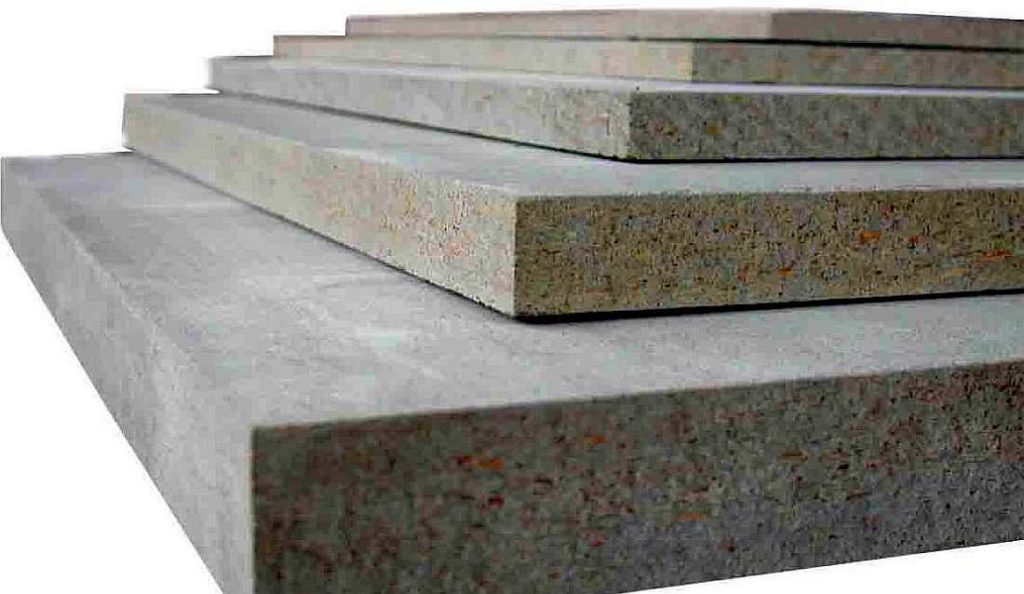

OSB, OSB made from specially prepared wood chips. Positive properties are strength, environmental friendliness of OSB-2 and higher modifications. The material is easy to process and the panels are easy to adjust to the desired size. Among the disadvantages are flammability, rapid destruction in the open air, minimal resistance to moisture.

Fibrolite make cement mortar and wood fibers treated with minerals. The material is not subject to open combustion, weakly absorbs moisture, has high adhesion, and is easy to process. With constant interaction with moisture and undergoing freeze-thaw cycles, fibrolite is rapidly destroyed.

Glass magnesite 15% consists of wood chips, it contains magnesium oxide, magnesium chloride, perlite. To impart strength, use a fiberglass mesh. Magnesite glass sheets do not burn, withstand 50 freezing cycles without significant loss of properties. Despite its low water absorption, the material is not used for installation in a humid environment.

Cement particle boards most resistant to moisture, so the house can do without finishing for some time. The material is heavy, therefore, the sheets are produced in smaller sizes, which increases the construction time.

The decision about which type of self-supporting insulated wire to choose is made based on the advantages and disadvantages of the building material.

Consider when choosing:

- climatic conditions terrain: average annual temperatures and precipitation;

- the main purpose of the building;

- panel availability in the region of construction, taking into account the cost of delivery to the construction site;

- geometric house size including the height of the ceilings;

- manufacturer's reputation, availability of safety certificates and results of laboratory tests of finished products;

- opportunity to order ready-made house kit with elements for framing door and window openings - no waste, often pays for the cost of sawing and sampling grooves in the insulation;

When buying, check the errors in the dimensions of the sides and diagonals yourself. If the tolerances exceed 3-4 mm, there will be gaps between the plates during installation.

Construction features

At each stage of construction, there are nuances that can reduce costs without losing quality.

Foundations

A monolithic slab is expensive, but it allows you to make the floor of the first floor without using a KTP, as well as equip a warm floor.

Shallow strip foundation makes it possible to save on the arrangement of the base, but is poorly suited for heaving soils.

Pile type the foundation is easy to make by hand with one assistant. The construction speed increases, as there is no need to wait for the concrete to gain full strength.

Tools and materials

Of the tools for building a house you will need:

- perforator for attaching the timber to the concrete base;

- screwdriver or drill with adjustable speeds;

- groove knife - electrical or mechanical;

- hand-held circular saw for cutting SIP.

Consumables are:

- galvanized self-tapping screws 20-30 mm longer than the OSB thickness;

- anchors for attaching the strapping bar to the foundation or threaded rod and nuts for pile foundations;

- galvanized corners for fixing timber;

- joint sealants;

- roofing material for waterproofing walls from foundations.

Particular attention is paid to the quality of the timber. It should be straight and dry, and its width should correspond to the thickness of the insulation in the self-supporting insulated wire.

Building walls

The construction of walls begins with the arrangement of waterproofing. The foundation is treated with bituminous mastic and rolled waterproofing material is laid around the perimeter of the house.

Algorithm for building walls uncomplicated:

- Attached to the foundation strapping barpre-impregnated with an antiseptic and treated with a flame retardant.

- Mount corner bar to the strapping, using galvanized corners, braces are installed for stability.

- Make grooves, removing the insulation from the necessary sides of the KTP, if the grooves were not on the plates initially.

- Install and fix the panel with self-tapping screws to the strapping and corner beams, for stability, the part is abutted with slopes.

- Mount the second panelcreating a corner of the house.This sequence will give strength and stability to the finished site. A gap of 3-5 m is left between the slabs for thermal deformation.

- By attaching the next vertical beam to the strapping and installing the next panel, continue to build the wall.

- Window and doorways equip with elements of plates of the required size.

- As the walls build, the top of the panels tied with a strapping bar, which is completely recessed into the groove.

- Cover the resulting SIP frameresting them on the outer walls and partitions. If the span is greater than the length of the panel, use a beam for lengthening.

- Mount piping and walls of the second floor.

Finishing

The choice of finishing option depends on the SIP material.

Fiber cement, glass magnesite and DSP can be plastered. OSB and plywood can be painted.

Exterior walls, as a rule, are covered with siding made of various materials, having previously provided waterproofing.

Internal walls of self-supporting insulated wire with OSB and plywood panels are covered with plasterboard or clapboard.

Frequent mistakes when building from self-supporting insulated wire

It is important not to deviate from the technology during the construction phase.

Construction errors:

- storage of self-supporting insulated wire in the open air, without moisture-proof film;

- work at negative temperatures or when the thermometer readings are above 25–30 ° С;

- work in rainy weather;

- the use of cheap panels, which most often indicates violations in production technology;

- poor waterproofing between the foundation and walls;

- using boards instead of timber;

- the absence of rafters when arranging the roof - with a span of more than 2–2.5 meters, the self-supporting insulated wire is deformed under load;

- insufficient ventilation.

.