Sealing compounds are widely used in repair and plumbing works for sealing seams and joints. For correct installation, you need to know the curing time of a particular product, as well as have an idea of how you can and how you can not accelerate it.

Description and properties of sealants

Scope of application

Sealants are used for the following types of work:

- sealing gaps when installing door frames and window frames;

- laying ceramic and stone tiles;

- sealing the gap between the bathroom and the wall, sealing joints in the areas where the sink and plumbing fixtures are connected, working with water and sewer pipes;

- electrical installation;

- arrangement of the roof and the space under it (for processing seams);

- laying laminate.

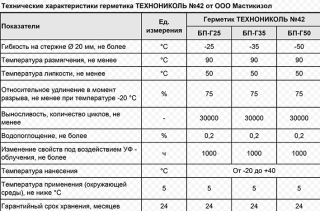

Main characteristics

- strength;

- resistance to deforming influences;

- elasticity;

- the degree of adhesion to materials;

- the presence or absence of the release of harmful substances into the environment;

- service life (inside the room and when used for outdoor work);

- the degree of shrinkage during hardening (if the composition hardens after application).

For some types of work, only special productswith characteristics that are important in the given operating conditions. Examples include:

- Sealing gaps in aquariums: for this, only environmentally friendly formulations that meet strict safety requirements for animals are suitable. Tensile strength is also important - it should be more than 25 kgf / cm².

- Sealing joints exposed to high temperature environments: fire-resistant products are needed for this purpose. To work with a home or bath stove and similar units, as well as to seal joints in mechanisms, compounds are used that retain properties when heated, resistant to oils and do not react with metal surfaces.

- Treatment of bathrooms, swimming pools, kitchens and similar biologically aggressive premises: it requires products with antiseptic and fungicidal additives that prevent mold and mildew contamination. But it is forbidden to use such sealants to repair things that come into contact with food (unless the packaging indicates that such an application is acceptable).

Varieties

Depending on the composition of the base they are divided into several groups:

- Silicone Rubber Sealants Is the most common class.They are durable, do not react with the components of the environment, adhere well to the surface, and are resistant to ultraviolet radiation. Some products in this category can withstand temperatures up to +300 degrees. They are available in a wide range of colors, but cannot be dyed at home. They are used for various types of household and industrial work, including the repair of bathrooms, aquariums, the installation of polycarbonate greenhouses and gazebos. Such sealants are acidic and neutral... The former are cheaper, but they have a narrower range of applications: they cannot be used for cement, marble, aluminum and other materials that form soluble salts when interacting with acetic acid.

- Acrylic compounds suitable for indoor work. Usually they are filled with inactive seams. For external embedding, as well as for places that imply regular contact with liquids, these products are not suitable due to their tendency to deteriorate in a humid environment. These sealants adhere well to various materials, do not contain toxic ingredients, and have an affordable price. The finished seam can be given the desired shade with acrylic paint.

- Polyurethane compounds suitable for a variety of interior work, including the installation of air conditioners, ventilation systems, roofing. For outdoor use, they are rarely used due to exposure to ultraviolet rays. They adhere well to many types of substrates.

- Polyisobutylene formulations usually used when working with double-glazed windows for primary sealing. They adhere well to glass, steel and aluminum surfaces. The limited scope of application is associated with the low ultimate strength in cold air. Moreover, such sealants have a number of other advantages: affordable price, elasticity, impermeability to water vapor, UV resistance. Since there are no solvents in the composition, it does not emit harmful substances into the environment. The color of these products is always black.

- Bitumen based sealants well suited for roofing, working with greenhouses and drainage systems. They adhere well to many building materials and withstand frosts without problems, but they cannot be used in high-temperature environments.

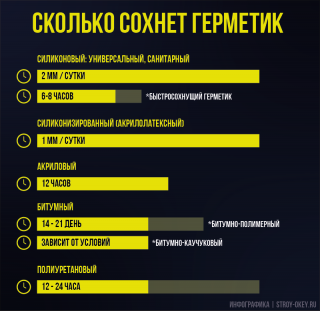

Drying time of sealants

- Drying time acid type silicone sealant small - only 5-6 hours... Neutral products freeze more slowly - about a day, while the air temperature should not be lower than +5 degrees.

- Surface acrylic the seam dries quickly - only in 2 hoursbut the final hardening process can take up to 25 days.

- Compositions on bitumen and polymers completely freeze everything in 3-4 hours... If rubber is added to the bitumen, the period will be completely different - 2-3 weeks.

- Polyurethane products dry quickly - from several hours to a day.

How to speed up the process

It is possible to reduce the curing time of the silicone sealant in the following ways:

- Apply the composition in one layer. If there are several of them, the surface hardens in a matter of hours, and the lower areas take noticeably longer.In addition, when applied this way, the sealant is easily exfoliated.

- After the initial hardening of the surface, handle the joint carefully, avoid touching.

- Don't make the seam too wide.

- Arrange in the room draft.

- Little heat up the air in the room heater (but do not overdo it - the temperature should not be higher than +30 degrees).

- Spray a small amount of water onto the joint.

How to accelerate polymerization

There are ways to speed up that strictly prohibited, otherwise it will not work to get an even seam:

- lowering products into water;

- lowering the temperature to negative indicators;

- local heating of the seam (for example, with a hairdryer).

Rules for applying formulations

For the bathroom, it is recommended to purchase a neutral sanitary sealant with fungicidal additives. This will protect the surfaces from fungus and other parasites. Such a product is also suitable for the installation of water pipes. Since the seam between the bathroom and the wall is wide, the drying time for it will be longer - about 2 days. If the bathtub is made of acrylic, you should take a sealant on a similar basis.

Working temperature and humidity

Desired values of environmental parameters (temperature and humidity) indicated on the packaging... As a rule, it is recommended to apply the composition in a warm room. Most sealants should not be applied when the humidity is more than 80% or during rain (even light rain) - this will increase the drying time and can create uneven joints. Both acidic and neutral compounds like above-zero temperatures (the optimum is from +5 to +30 degrees), but the former harden faster in humid air, and the latter in dry air.

Helpful hints

Before applying sealant remove dirt and grease from surfacesand then let them dry. Places that the composition should not get to are covered with masking tape.

You need to apply the product with a construction gun (a tube is inserted into it). The device is brought to the plane at an angle of 45 degrees. In this case, it is important to achieve a continuous strip with the same thickness throughout the entire length. Excess sealant can be removed with a cloth or spatula.