Often the price for timber, boards and other sawn timber is set per cubic meter of volume. Without sufficient experience, it is sometimes difficult to understand how many pieces of material should be released. It is important to be able to determine the weight of a cube of wood products, as well as the number of elements in a batch. This will also help to find out if the goods were dispensed correctly and what the deviations from the nominal parameters are.

Why you need to know the amount of timber in a cube

The GOSTs in force in the country indicate that building materials made of wood must have measurable indicators - length and parameters that determine the cross section.

Knowledge of linear dimensions allows find out the volume of a unit of production (for example, timber), and also calculate the cubic capacity of the number of pieces required for the construction of a building in accordance with the calculations. This will also make it possible to find out how much you will have to pay for the required amount of material (after all, the price is often set on the basis of a cubic meter) and find out its mass.

Calculation procedure

To find out the volume of a unit of lumber, you need to be able to determine its cross-sectional area. For calibrated edging bar It's easy to do this: the units have well-defined width and thickness and have a rectangular cut.

If there is a significant variation in parameters between elements, calculations will be more difficult. The section of a profiled bar can be decomposed into simple shapes (rectangles), find the area of each of them and add the resulting values together.

What you need to consider when calculating

When determining the number of bars in one cube, as a rule, shouldn't get a round number... Usually, a value with a fractional part is obtained - for example, 7.33 pieces. The seller can round this number down to a lower integer in order to save... In this case, when buying several cubes of lumber, you may find that it came out several bars less than necessary. Therefore, when preparing, it is better to calculate not the required volume, but the maximum number of units of production that will be required for certain works.

An invoice must be issued upon purchase, which provides information about the cubic capacity of the released timber and its quantity in pieces.

How to convert a running meter to cubic

The ratio of these units to each other for different sawn timber will not be the same. It depends on the linear parameters of the bars.

An example of calculation for a bar with a rectangular section with sides 150 and 200 mm it will look like this: 1 * 0.15 * 0.2 = 0.03 m³. The factor of 1 means 1 running meter, and the other two are the length and thickness values converted to meters.

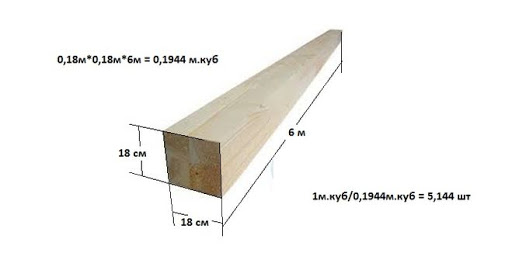

To find out the volume of a timber with such a section of 6 m long, you need to multiply the indicators: 6 * 0.03 = 0.18 m³. You can determine how many units of this product will be in a cubic meter: 1m³ / 0.18m³ = 5.55 pieces.

Calculation formulas for edged and profiled timber

To calculate how many such products are in one cubic meter, you need to divide 1 m³ by the resulting volume of a piece: n = 1 m³ / V, where n is the number of bars in a cube, V is the volume of one piece of sawn timber. Given the above formula for volume, it turns out: n = 1 m³ / V = 1 m³ / a * b * l.

A similar principle applies when working with profiled timber.The calculation of the number of units is similar, but the cross-sectional area is considered somewhat more complicated. A cut of a profiled bar does not look like an even rectangle, like an edged one, but looks like a composite figure that can be decomposed into several simpler ones (as a rule, rectangles and trapezoids). Accordingly, to calculate the section, you need to find the area of each of these figures, and then sum them up.

Further calculations are carried out in the same way as for edged timber: the cut is multiplied by the length and the volume of one piece is obtained in cubic meters, and then 1 m³ is divided by the resulting value.

Timber volume tables

There are tables where data on the volume of a unit of a bar based on its linear dimensions... They can be used when making calculations and planning the purchase of building materials. One of these tables is shown below. It gives the values of the volume of 1 piece of timber of the most common sections, having a length of 6 m (this is the most common indicator):

| Sides of the section of the bar in millimeters | Volume of 1 piece, length 6 meters in m³ |

| 200x150 | 0,18 |

| 100x100 | 0,06 |

| 150x50 | 0,045 |

| 150x100 | 0,09 |

| 100x50 | 0,03 |

| 150x150 | 0,135 |

| 200x100 | 0,12 |

| 50x50 | 0,015 |

Also, for calculations, you can use tables containing data on the number of bars contained in a cubic meter of lumber. Below is one of them. The data in it is also valid for a timber length of 6 meters.

| Sides of the section of the bar, mm | The number of units contained in 1 m³ of building material |

| 200x150 | 5,5 |

| 100x100 | 16 |

| 150x50 | 22,2 |

| 150x100 | 11 |

| 100x50 | 33,3 |

| 150x150 | 7 |

| 200x100 | 8 |

| 50x50 | 66,6 |

Also, to determine the number of product units in one cubic meter, you can use online calculator. The user needs to enter in the fields the values of the corresponding linear parameters of the unit of production. The resulting result will be valid for the case when all copies of building materials have the same dimensions and a simple quadrangular sectional shape.

Weight of a cubic meter of timber

What does the mass depend on

The weight of the lumber depends on the following factors:

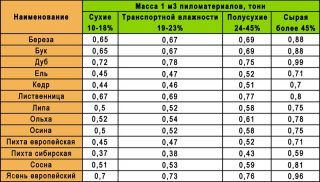

- Wood moisture... The higher the quality and longer drying of the raw material and the lower the water content in it, the lighter the cubic meter of the product will be.

- The density of the tree. The value of this indicator will be different for different breeds. The highest indicators are shown by boxwood, ebony and bog oak. Their density reaches 1000-1300 kg / m³. Common oak, hornbeam, acacia have indicators of 700 kg / m³, conifers - 500. Cork wood is distinguished by its lightness: its density is 140 kg / m³. With the same moisture content, the mass of a cube of lumber will differ for different species.