Before you build a house, shed or even a fence, you need to calculate how much material is required and how much it costs. For this, it is not enough to calculate the required volume of material. The total should be translated into the value in which the goods are offered by the sellers.

Why calculate the cubic capacity of the boards

During construction, the master deals with boards or timber. It is lumber with a certain thickness, length and width. When determining how much wood will be needed for a wall or floor in a room, you need to take into account the size and volume of the board or timber.

However, manufacturers do not offer lumber per piece - it is unprofitable and inconvenient. It is sold in packages - euro pallet, pallet, where a certain volume is occupied by a certain amount of forest.

There is another quantity - cubic meter... When calculating, it is even more convenient, since it assumes not the number of boards, but the volume of material. It is easier to calculate the cubic capacity of lumber. In addition, the cost of the material is also easier to determine in this way.

Popular board sizes

GOST for coniferous boards:

- Length - from 1 to 1.65 m with a step of 25 cm.However, today another size has become very popular - 6 m.

- Width - from 75 to 275 cm with a step of 25 cm.

- Thickness - 16,19, 22, 25, 32, 40, 44, 50, 60, 75 mm. The thickness is consistent with the width of the product.

Dimensions are for edged boards. Unedged can have slightly different dimensions. But since this product is measured with an indent of 15 mm and without taking into account the bark, their custom sizes are the same.

Length:

- 0.5 - 6.5 m with a graduation of 10 cm for hardwoods;

- 0.5–2 m in 10 cm increments from soft rocks;

- 2–6.5 m in 25 cm graduations for all types of wood.

Thickness - from 19 to 100 mm with the same pitch as for conifers.

Width:

- edged - vary from 60 to 200 cm in steps from 10 to 20 cm;

- unedged - 50 cm and above with a graduation of 10 cm.

Dimensions are determined for finished products. This means dry wood with a moisture content of up to 22% and with a moisture content of more than 22%. This must be taken into account.

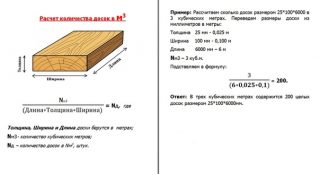

Calculation formulas

The number of boards in a cube is determined simple calculation. Calculate the volume of one element - multiply the width, length and thickness. And then divide 1 m³ by the resulting volume. For example:

- let the dimensions be 25 * 100 * 6000 mm - one of the most popular options;

- the volume of 1 such board will be 0.015 m³;

- the quantity in 1 cube is 66.6 pieces.

The result is rounded down, since there are no scraps in the cube.

Since the builder often needs to buy not 1 cubic inch, but the required number of products, do inverse calculations. Calculate the cubic capacity of the volume that is required for the construction of a building or fence. To do this, find the volume of the board and multiply by the required number.The latter indicator is usually recognized by dividing the surface area by the area of the board. Then multiply the volume of 1 element by the desired number. As a result, they get cubic capacity - the exact volume of wood required for construction.

You can calculate the quantity or volume using an online calculator.

Cubic capacity table

Ready-made tables are easy to find. Usually, the ratio of the dimensions of the board and timber to the cubic capacity and data on the mass of lumber and the mass of 1 cubic meter are given. And although the physical parameters of planed and unedged boards are somewhat different, in fact, their useful area is the same. Therefore, the same tables are used for products of any type.