Clapboard is a sheathing board obtained by sawing and processing wood. The variety of options makes it difficult to choose, and the significance for a particular type of work depends on the cleanliness of the base and surface. For a quick classification, an idea of the grade of the finishing material is used. The species of wood is important, since the varieties of lining made of pine, spruce, larch can admit a different number of defects.

What does "grade" lining mean?

Variety - this is a group of materials with certain attributes of belonging (decorative, quality or useful). Features distinguish the series from other copies of the same species.

When attributing lining to a certain grade take into account factors:

- the material from which the products are made;

- type of product and lock;

- sizes;

- the presence of defects within the tolerances.

The type of cladding board, appearance depends on the material (raw material). The type of joint indicates the possibility of combining with other materials, the likelihood of creating a seamless coating. GOSTs indicate the permissible number of distortions, knots and other defects, the presence of which assigns the product to a certain grade.

GOSTs

In Russia, in the national economic sectors, the state system of standards (SSS) has been adopted. This division increases the efficiency of the use of building materials, improves the quality of the products themselves.

Various standards differ in scope:

- state (GOST);

- republican (PCT);

- industry (OST);

- standards of associations and enterprises (STP).

The regulations indicate clear signs of classification by varieties. The development of technical specifications by each enterprise is allowed, but the indicators for differences by grade are established on the basis of the standard requirements of GOSTs.

The standards for determining the class of lining by grades are set out in GOST 8242 - 88. The international principles of standardization given in the documents DIN EN 15.145 - 2006, DIN EN 14.519 - 2005, DIN EN 14.915 - 2006, DIN EN 68.126 - 1986-10 are also used.

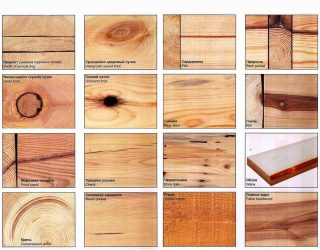

Types of defects

Defects and defects of the lining are estimated by the number of lamellas per running meter. The dimensions are used to evaluate the joint clearances, cracks and overlaps in excess of the norm during the joint.

Defect sorting options:

- the knot diameter is found as the average of the minimum and maximum cross-sectional dimensions;

- wormholes and pricks are measured by the largest diameter, taken in pieces on a p / m strips;

- cracks are distinguished by their length;

- resin pockets are counted in pieces per linear meter, indicate the width and length;

- spots, blueness, darkening, fungal lesions, mold are measured in width, length, area is calculated, indicated as a percentage in relation to the total square.

Side edge defects are measured by the distance from the edge of the scrap to the edge of the lining in millimeters. Warpness is determined with a ruler for maximum deflection.

Material classification

Depending on this there are types:

- Standard... The base base has a cross-section in the form of a beveled trapezoid with grooves on the back. It is connected in the thorn-groove type.

- Euro lining. Features a wider spike for a secure fit. After installation on a plane, longitudinal grooves are visible.

- Calm. The type of lining has rounded corners, otherwise this type does not differ from the Standard.

- Softline. Considered a premium category for home decoration. The edges of the strips are smoothly rounded, so the surface is almost perfectly flat.

American used to create a herringbone effect on the facade. The lamellas are distinguished by their non-parallel arrangement of the outer and inner sides, therefore, each boarding board is installed at a slight slope.

Extra

This type is difficult to produce, despite the high cost:

- it is easier to cut out the necessary pieces of material from oak or pine trunks, since the species are not prone to knot formation and rotting;

- spruce and birch are used less often - it is difficult to choose the required lengths on logs that are replete with knots, hence the increased cost of lining.

Premium

Product features:

- allow 1 defect per running meter;

- produced from the middle part of large trunks;

- are cheaper than the Extra class.

Usually knots or cracks are located at the end of the lamella, so they are cut off and get defect-free material at a lower cost. After installation, they are treated with protective compounds.

Class A

Sorting features:

- 1 captive knot and 1-2 cracks (up to 3 cm long) are allowed on a linear meter at the same time;

- for the manufacture they take conifers, birch, beech and linden, aspen are preferable from deciduous ones.

In the final finishing, a putty is used to seal cracks and strengthen places around the knots. From above they are painted with colorless varnishes or matte compounds. Used for rooms, corridors, balconies, facades, cladding inside baths (linden).

Class B

The procedure for selecting specimens of grade B lining:

- allow 2 resin pockets and a knot for 1 p / m;

- allow a blind crack (up to 3 cm) or chip;

- take on the presence of blurry dark spots that are not contrasting with the main background.

Class B lining is installed as a finish in non-residential, technical premises. The material is suitable for cladding walls and ceilings in corridors, storerooms, dry basements. Designers use picturesque knots to decorate interiors in an exclusive style.

Class C

Number of defects in class C material:

- large cracks (from 3 cm);

- chips on the surface, curvature of the lamella;

- incorrectly executed lock;

- ugly texture, stains.

Saw the trunk out of the sapwood. Numerous defects lead to inconvenience during installation, since each element must be selected. Lining of this class is installed in garages, sheds. Boards are made of small length (up to 2 m), since long lamellas are too curved during drying.

Brief comparative characteristic

In finishing combine varieties Premium and Extra, while the first type is divided into pieces that are used in inconspicuous places, for example, behind the battery, on inclined planes, slopes.One-piece lamellas without flaws are installed on the plane of the visible wall.

Class A is more suitable for cladding the facades of cabinets, external walls of the house. Compared to Premium, the material is cheaper, but it can be cut into suitable lengths to select parts with a clean surface. Two grades A and Premium also combine in decoration. Lining of category C is not used in the interior of living rooms and outside the house.

The choice of material for finishing

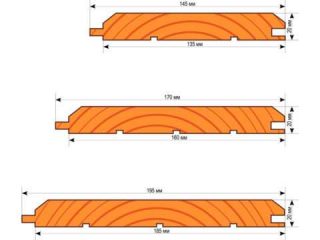

Standard strip sizes:

- thickness - 10 - 25 mm;

- the length of the lamellas is 0.6 - 3 m;

- width - up to 16 cm;

- the height of the spikes on the lateral edges is 4 - 8 mm.

Errors in thickness and width are allowed - 1 mm, in length they are allowed up to 5 mm at six meters.

Walls and ceilings in the country

Selection tips:

- coniferous varieties of lining are popular - the material has a pleasant smell, does not deteriorate for a long time;

- beautiful texture in wild and simple oak, birch, therefore, living rooms, children's rooms, bedrooms are trimmed with clapboard from this type;

- for the bathroom, kitchen choose larch, spruce, pine - species with high moisture resistance.

By types, they give preference to Softline, Euro-lining, Standard.

Finishing the cottage inside and outside

For the cottage, high-grade material is used, the Extra and Premium varieties are preferred.

Finishing features:

- rooms, an office, sleeping quarters inside the house are sheathed with lining of hardwood, using a beautiful pattern of fibers of fir, pine, birch, alder, elm;

- conifers are used in wet rooms of bathrooms, kitchens, where there is a large accumulation of steam and moisture, larch is well suited, but it is more expensive.

Estimated cost

The price varies depending on the type of material, grade, type of wood.

Key cost indicators:

- Premium and Extra are sold at 300 - 800 rubles / m²;

- class A is offered at 250 - 600 rubles / m²;

- grade B - there are options for 180 - 260 rubles / m²;

- low-grade material of class C can be bought for 100 - 150 rubles / m².

It also influences the location of the region in relation to the sites of forest felling and woodworking complex. In this case, the price includes not only production costs, but also transportation costs.