The resistance of concrete or brick to bearing and compressive loads is very different. This limits the scale of construction. Reinforcement of concrete structures with reinforcement is a rational and profitable way to significantly increase strength.

General information about fittings

All reinforcement elements are divided into 2 categories:

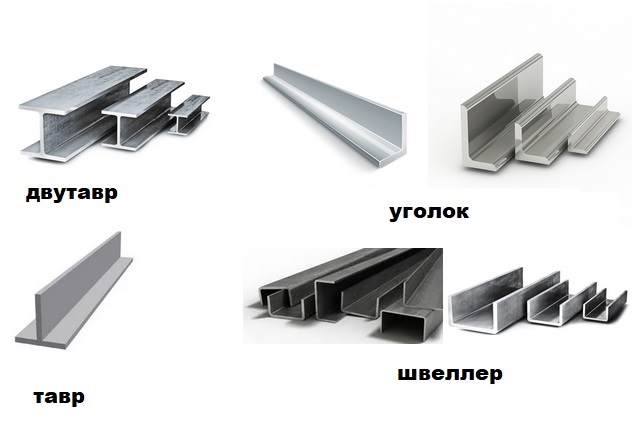

- tough - channels, angles, I-beams and other types of rolled metal;

- flexible - rods, smooth or corrugated, as well as welded mesh or frames assembled from rods.

Depending on the diameter or dimensions of the element, as well as its manufacturing method, it is used in a wide variety of construction finishing works, as well as in the automotive industry, car building.

The need for application

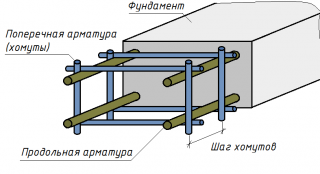

Bars, mesh, corners are placed in the depths of the concrete part - walls, columns, foundations. After the material has hardened, the frame and concrete form a single whole. In this case, the concrete perceives the vertical bearing load, and metal rods provide tensile and compressive resistance.

Rebar elements can be stacked in different ways. When reinforcing the concrete screed, the mesh is positioned freely and is poured with concrete. In reinforced concrete structures, the frame is poured with concrete when it is stretched. At the same time, the profile retains residual stress and withstands higher loads. To reinforce prefabricated structures and create a stressed frame, different rolled metal products are used.

The range of fittings is huge... Therefore, this principle - reinforcement with a frame and connection with the base material - is used very widely.

Application area

- Erection of the foundation - slab, tape, columnar. Most often, an unstressed frame is used here, the volume and structure of which is determined by the future load.

- Construction of bridges, dams, hydroelectric power plants - heavy reinforcement, often stressed, is used; for this, parts of a bridge or dam must be produced at the factory.

- Construction of industrial workshops - here the main task of reinforcement is to resist the heavy weight of the equipment and the high vibration load.

- Erection of walls, columns, other supporting structures - all types of reinforcement from I-beams to flat meshes are used, depending on the size of the load.

- Finishing work - reinforcing mesh made of a bar less than 3 mm or made of composite materials is used for plastering, sealing defects, and repairing concrete structures.

Lightweight nets are also used in the construction of fencing, and heavy ones for the construction of animal enclosures.

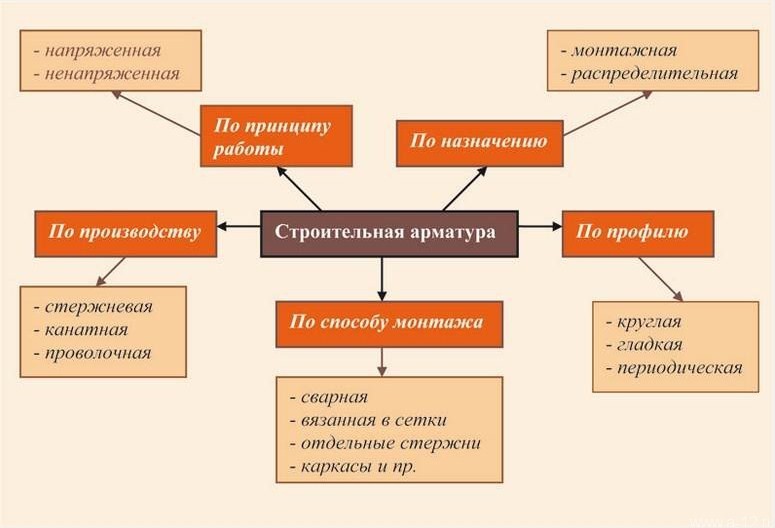

Product classification

There are a huge number of types of fittings. Rolled metal products are classified according to technical characteristics, purpose, design features and many other factors.

The main parameter of choice is load resistance, and this is due to the size of the parts and shape.

Piece fittings - corner, I-beam, channel. Such elements can form the supporting frame of a building or bridge. However, when reinforcing reinforced concrete structures, they are used individually and in small volumes.

Rod fittings - rods made of black or galvanized steel, cold or hot rolled. There are 2 types:

- smooth - no relief on the surface;

- grooved - or periodic, on their surface there are protrusions with a certain step. Ribbed bars are better anchored in the concrete slab.

Grid - the rods are laid perpendicular to each other and welded. Distinguish between heavy nets - made from rods with a diameter of 10 to 40 mm, and light, obtained from rods with a diameter of 3-10 mm. The former are issued in the form of flat cards and are often used as a basis for a volumetric frame. Lightweight nets are available in rolls and are more commonly used for screeding.

This is the most approximate classification that allows the builder to determine what type of rolled metal is required for the slab, floor, grillage.

By material

- Metal - is made from different grades of steel. The frame made of such rods is extremely strong, providing maximum resistance to bending and tensile loads. When constructing the frame, the rods can be bent, welded, and wired.

- Composite - used for the manufacture of glass fibers, basalt, carbon. Fiberglass reinforcement is usually used in cases where it is necessary to prevent the passage of current. Basalt meshes are often used to reinforce porous or cellular concrete masonry.

Polypropylene mesh for plaster is also a type of reinforcement and works in the same way as iron, but only in a thin layer of material.

By design

- transverse reinforcement - prevents the appearance of cracks, shearing stresses occurring near the supports, and also connects tensile zones and compression zones, redistributing the load;

- longitudinal - perceives tensile or compressive stress and does not allow the formation of vertical cracks.

The metal structure often combines longitudinal and transverse reinforcement.

By appointment

- Working - provides higher resistance to loads. The elements perceive the effort in shares of the basic load. For prestressing reinforcement, it is allowed to take only material of the working category.

- Constructive - or distribution. Its task is to prevent displacement and cracking under the influence of the temperature factor, when the base material expands or shrinks. It is installed in areas most susceptible to local stress and distributes it over the entire area. The section of the elements is calculated according to the minimum percentage of reinforcement.

- Mounting - combines structural and working fittings into a single whole. Increases resistance to various types of loads.

- Anchor - embedded parts made of round, angle or strip steel, which are placed in the structure before concreting. They are used to weld reinforced concrete structures together.

From a structural point of view, working or assembly elements can have a very different appearance.

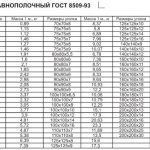

Reinforcement range

The metal profile of the most different type and type is produced. According to GOST, it is most convenient to distinguish it by mechanical properties... The latter, to a certain extent, depend on the diameter of the elements, the cross-sectional area, and also the step of corrugation, when it comes to working rods.

Classes according to GOST

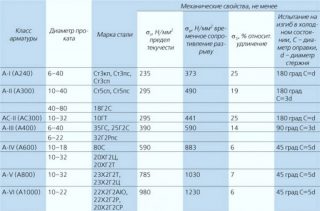

According to the technical characteristics and the relief of the profile, they are distinguished 5 classes of reinforcement according to GOST.

- A1 - (A240)... Thin smooth rods made from hot rolled steel. Bars with a small diameter are produced in the form of coils, with large ones - only in the form of rods. The bar diameter ranges from 6 to 40 mm. The products are distinguished by their high plasticity and the ability to elongate in tension. Reinforcement class A1 is used as transverse in the form of free-lying elements.

- A2 - has the same characteristics as products of class A1, but differs in thickness - from 1 to 8 cm. It is produced only in the form of rods that can be welded into flat heavy meshes.

- A3 - (A400)... The most common option in construction. Large section iron profile with corrugated surface. The cross tabs are positioned at a defined pitch and slightly sloped. Usually it is made of structural low-alloy steel: 35GS and 25G2S. The first option is quite suitable for welding. However, the compounds obtained in this way are not distinguished by high plasticity. As a result, in the manufacture of monolithic reinforced concrete structures, it is necessary to abandon this type of connection. Reinforcement made of 35GS steel is used to strengthen the concrete structure and impart rigidity to it. It is assumed that the reinforcement will be under a thick layer of concrete.

- A4 - type of prestressed working reinforcement. The diameter of the rods varies from 1 to 3.2 cm. They are used for the construction of frames, both welded and wired.

- A5 - made from hot-rolled, thermally hardened steel. For it, an alloy is taken from a cheaper carbon steel, which makes it possible to reduce the cost of reinforcement. However, due to thermomechanical hardening, the profile has better flow characteristics, and this simultaneously increases both the strength and flexibility of the product.

Classification by class allows you to quickly determine what type of reinforcement is required for certain jobs.

Dimensions, diameter, weight, cross-sectional area

Marking and decoding

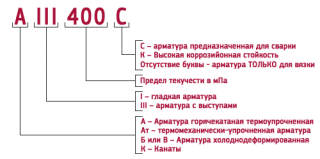

- the first letter denotes the type of reinforcing bar: A - hot-rolled or cold-rolled steel, B - cold-worked, K - ropes;

- reinforcement class according to GOST - А240, А400;

- the following letter defines special properties: K - corrosion resistance, C - welded connection, T - thermally hardened material;

- rod diameter in mm.

Rebar ends for faster visual identification painted in different colors... For example, rods made of low-alloy steel of class A4 are painted red, and A5 - red and green.

The code is reproduced on each rod. Details are given in the manufacturer's certificate.