For flooring in open areas or in very damp rooms, ordinary material is not suitable. The tree swells with moisture, damp, deteriorates. The best choice for decking on terraces or verandas is WPC decking.

What is decking

Decking or decking is a structure designed for finishing decks, terraces, gazebos, garden areas and paths... In appearance, it resembles an ordinary tree, but has a different structure.

WPC board is solid or consists from 2 planes, connected by perpendicular, rather thick partitions. The structure is rigid, very strong, designed for high mechanical loads, but at the same time it is much lighter than a solid flooring of the same thickness.

The cavities inside provide 2 undoubted advantages. Firstly, when moisture gets inside, it simply flows out of the cavities, without lingering inside and without subjecting the material to destruction. Secondly, cavities filled with air provide excellent thermal insulation. Therefore, the floor made of terrace boards remains warm and pleasant to the touch until severe frosts.

The material is made from sawdust and polymer resins, therefore it combines the positive qualities of plastic and wood.

How do WPC decking boards

- wood flour - 30–80%, and even sunflower cake and rice husks can be used to reduce the cost of the material;

- thermoplastic polymer - polyethylene, polypropylene, polyvinyl chloride;

- modifiersimproving the technical characteristics of the product.

Decking technology from the KDP is simple.

- In the first stage crush wood waste - slab, crooked logs, trimmings. The resulting wood flour is dried, since only very dry raw materials are suitable for the material.

- Shredded polymers in 2 stages. First, the materials are crushed in a shredder or granulator, and then they are brought to the consistency of flour in a mill.

- The polymer is melted - they are heated no higher than + 200 ° С to get rid of excess water.

- The original the products are combined and mixed. The higher the proportion of wood in the composite, the more powerful equipment you need to use.

- A mixture of plastic and shavings again melted and then fed to dies... The workpiece is squeezed out through the holes and a board of the required shape and type is obtained.

- The products are cooled, patterned and cut to length.

Technical and operational qualities

There are 3 types of material in composition. It defines the technical parameters.

- Portions of wood flour and polymers - 70 and 30% respectively. Some excess shavings make the material more prone to swelling and reduce its resistance to rain and frost. In addition, due to the loss of elasticity, the material becomes brittle. The service life is 5–7 years in the middle latitude.

- With an excess of polymer - 60%, the board looks more like ordinary plastic. It keeps heat worse, is vapor-proof, and also rather slippery.

- Equal proportions of the components are considered the optimal ratio. Decking ideally combines the properties of wood and plastic.

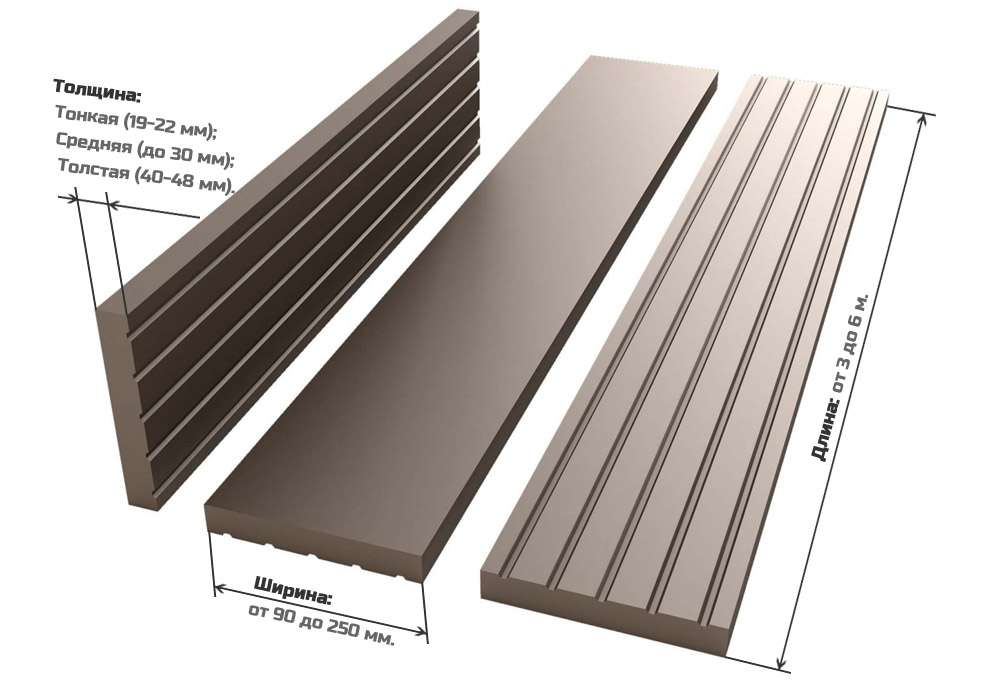

The dimensions of the deck depend on the type. The plank thickness ranges from 18 mm to 48 mm. The latter option can withstand a load of up to 2000 kg per 1 m². Width - 9–25 cm. The length depends on the manufacturer, usually 1.5–3 m. Models of 4–6 m in length are also available for industrial use.

Types of WPC decking

- cast - more like ordinary boards, as they have a solid structure;

- hollow - the classic version with cavities and partitions.

Cast material is typically used for harsh environments.

- Corrugated - models are available with different frequencies and cutting depths. The slipperiness of the board depends on it. Such a floor is advised to be made in open areas. Water is distributed at different times along the grooves, and a person steps only on the ridges. The risk of falling is minimal.

- Smooth - more precisely, even, since the decking surface still retains some roughness. The smooth material is aesthetic and is often used for verandas and living quarters.

Smooth decking can be mounted in more decorative ways by laying out simple ornaments.

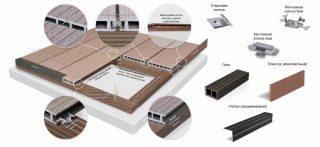

Installation methods

Decking is laid on logs... For fastening take clamps or special fasteners... There are two main ways to mount.

- Suture - the deck is fixed on the logs with a distance of 5–10 mm. This option is easier to install. Even a very large amount of water flows through the cracks obtained. However, grass can sprout through them, garbage can fall under the terrace.

- Seamless or deck, according to the type of "thorn in the groove". A standard joining method that gives the deck extra strength. If this method is used in an open area, make sure that it has a slope of 2-3 degrees for water drainage.