Terrace board is a fairly new material on the Russian market. This is the name of a wood-based material that has good decorative qualities and is practically neutral to environmental factors. It is used for a wide range of external and internal finishing works: laying paths on the site, facing glazed balconies, arranging the floor of gazebos, installing stairs in a residential building.

Technical characteristics of decking

Panels are made from different types of raw materials. The most environmentally friendly products are solid solid, made from resinous rocks with high density. It can be pine (the most budgetary option), larch or an expensive exotic tree.

A separate segment of such products - thermowood... During its production, the massif is subjected to high-temperature treatment (at + 150 ... + 190 degrees Celsius), due to which it becomes stronger and is almost not subject to destruction under the influence of moisture. In addition, when using such products, there is no problem of uneven floor shrinkage. Also, processing increases the life of the wood.

Also boards are made made of WPC (wood-polymer composite)... It is a mixture of resins with plastics (polypropylene and PVC are often used) or leather and paper waste. Such products can imitate a natural board. Some characteristics bring them closer to plastic cladding such as siding: ease of cleaning, no tendency to rot under the influence of moisture, fungus, insects and mold. Unlike a solid untreated board, the polymer composite does not need to be regularly treated with antiseptic compounds.

Product characteristics depend on the material from which they are made. For example, composite decking belongs to the G4 fire safety class, while a solid board is a more flammable material. The cladding tolerates temperature changes, extreme frosts (up to -45 degrees) and extreme heat well. The moisture absorption of composite products is about 5%. Such products serve for 10 years or more. The disadvantage of WPC panels is that they are prone to some fading when exposed to direct sunlight. The first signs of a decrease in color brightness appear after about a year of operation.

Standard sizes

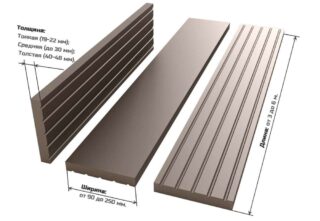

Most often, sizes vary within such a framework:

- Length from 1.5 to 6 meters. Products with a long length are usually not used for decorating private houses. They are used for arranging dance floors, piers, creating tracks.

- Thickness from 1.8 to 5 cm. This parameter affects the strength of the coating.

- Width 9-25 cm.

Decking is produced by a large number of enterprises in Russia and abroad. They do not adhere to a single standard governing sizetherefore the range of values will differ from manufacturer to manufacturer. Since the material is made using the same technologies, differences in dimensions will not affect the properties of the product.

If the linear dimensions of the board are known, it will not be difficult to calculate the area of its outer surface. To determine how many panels are required to cover a certain plane, you need to divide its area by the value of this parameter of a single product.

Product range

Although each company that manufactures boards has its own size range, it is possible to designate averaged values of linear parameters. Length composite products can be from 2 to 6 m, and their average width - 15-17 cm. Thickness such products are usually about 2.5 cm... These boards are capable of withstanding a fairly large weight (up to half a ton per square meter of area). Unlike products made from natural wood, in the case of a composite, there is no such a pronounced relationship between the massiveness of products (thickness and width) and their strength. The properties of the product depend more on the raw materials used for its production.

Composite boards are hollow and full-bodied. The second option assumes the absence of cavities in the structure of the material. Such a product is an imitation of natural wood, not only on the outside, but also on the cut. Hollow boards have cavities inside. Their production is beneficial in that it reduces the cost of the product by about 30%. At the same time, from the front side, they look the same as full-bodied. Nevertheless, the latter have better performance characteristics: they are more durable and can withstand significant loads. But for use in undemanding conditions from this side (where there is no pressure of heavy objects), hollow panels can also be purchased.

Natural boards have on average the following linear dimensions: thickness - 25-40 mm, width - 14-16 cm, length - from 1.5 to 6 m... Sometimes there are options shorter than 1.5 m. Usually these are products from exotic species, which are often also less thick (20-25 mm). In private construction, short boards are usually used: they are well suited for finishing loggias, gazebos, arranging paths in the garden. Large panels are more often used in crowded places. Although the size range of solid wood boards has a "tail" in the smaller direction relative to composite products, their mass is noticeably greater. And their ability to withstand large weights strongly depends on the thickness and width.

Some firmsmanufacturing composite products, in addition to the standard version, they offer a lightweight... In this case, less weight is achieved by reducing the thickness. For example, the domestic boards "Volga-decking" standard products are 3 cm thick, lightweight - 2.2... Most Russian firms produce WPC panels in lengths of 3, 4, 5 and 6 m. German manufacturers often offer only options in 4, 5 and 6 m. Werzalit Terraza boards are very thick (almost 4 cm).

What width and thickness to choose for the street

If the homeowner decides to equip a beautiful path in the garden, the question arises about the optimal size of the decking for the street. The length of the products is selected depending on the length of the structure and its configuration. The thickness is also determined by the purpose. If it will simple track, on which it is not planned to exert heavy loads, options of medium thickness (2-3 cm) are suitable. The same option is suitable for flooring in the gazebo... Installation stairs has more stringent requirements: the board must be very thick (4-5 cm). Sometimes, to achieve this parameter, double options are used.

Type of corrugated boards are selected depending on the place of installation. If they are purchased for a walkway or gazebo, the frequency of the profile should be such as to protect people from falling and at the same time not create inconvenience. For the installation of stair treads, lower frequency and profile depth are required.Double planks of high density with fine grooves are well suited.