Roofing paper is included in the group of materials used in roofing and other waterproofing works. It is a cardboard sheet processed with natural or artificial resins. The latter determine the properties of the resulting material.

Roofing varieties

Roofing board belongs to building materials with a cardboard base... Previously, coal tar was used for its production. After impregnation, the sheets were applied abrasive coating large or small fraction. Later in the industry began to use artificial resin.

You can find products without sprinkling, but they are less durable, the service life is short.

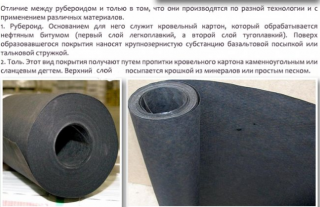

Sometimes people confuse roofing felt and roofing material or consider one material to be a subspecies of the other, however, there is a difference between them due to the composition of the impregnations used.

On sale meet several types of rolled cardboard products... They differ in their characteristics and scope.

- Unsurfaced product for waterproofing. This is the least strong roofing paper with a budget price. It may have no dusting at all or may have a fines coating. Its impregnation softens at high temperatures (40-60 degrees Celsius, depending on the brand). It is produced in accordance with GOST 10999-76 and is used for waterproofing the foundation and walls (including for underground work). It can also be used as the lower part of the roof covering, on which a more durable material is laid. If such a roll is left in water for a day, its mass will increase by more than a quarter. This is due to a pronounced tendency to absorb moisture.

- Roofing material with a parcel of sandusually bilateral. It is used for waterproofing structures when arranging roofs. Rolls are distinguished by the largest weight (up to 28 kg versus 23-25 for other brands).

- Coarse-grained roofing paper has the lowest softening point of the liquid composition (23-28 degrees). The coarse fraction is sprayed on the upper side, and on the lower, as a rule, small. On roofs with a shallow structure, built using roll coatings, such material is used as the top layer. All used sprinkles make the roofing stronger and more resistant to fire.

When the sheet loses its performance, it can be quickly replaced with a new one. Ease allows you to use it for structures that do not have a solid foundation. Flexibility allows waterproofing material to be laid at different angles. However, due to low strength and susceptibility to combustion roofing board is increasingly being replaced by more modern moisture-proof coatings. The material does not differ in aesthetics. Usually gray and black are on sale.

The material is attractive for its budgetary price, which, together with its performance characteristics, makes it suitable for barns and similar outbuildings.

Features of production

Used cardboard sheets are 1-2 mm thick.

The resins are melted and are brought to a temperature of 100 ° C in long (up to 4 m) narrow baths. Cardboard strips to be impregnated are immersed in them. At the end of this process, excess resin is removed from them with rotating rollers.

The products are applied dry topping on one or both sides (some brands do without it), dried with flue gases and allowed to settle.

Finally, the roofing paper is rewound into standard rolls.

How does the roofing material differ from roofing material?

The difference determines the composition used to impregnate the sheets. For the manufacture of roofing material, instead of mixtures with tar, liquid bitumen is used. The product is stronger and lasts longer.

The total consumption of these coatings is comparable. They are often stacked in several layers.

Roofing applications in construction

Usually the material is used as temporary replacement of a flat roof or as one of the components of its design.

Correct installation implies laying in at least two layers... If you limit yourself to one, the flooring will not withstand even one season of use.

If one of the parties has coarser dressing, she must be facing up... The first layer is mounted on a dry plane, and the others are laid on it after smearing with a resinous composition or mastic.

You can use this material for waterproofing walls and as one of the components of the insulation cake.

In an already constructed building, roofing paper is also used. It is used in the repair of leaks, as well as in the quality flooring under the tiles in the bathroom.