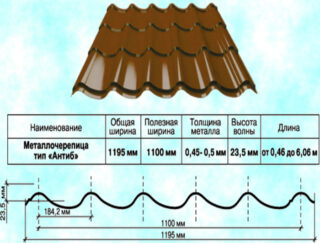

Metal tiles made by stamping and outwardly similar to classic ceramic tiles are becoming more and more popular. When installing it yourself, it is important not to make a mistake in the calculations, since the width of the metal tile and the length of the sheets may differ depending on the manufacturer and configuration, and when cutting, the stamped pattern is additionally taken into account.

Size Requirements

In 2018, GOST 58153 "Profiled metal roofing sheets (metal tiles)" was adopted and put into effect, which describes the requirements for raw materials, geometry, protective coatings and other characteristics of products.

The pattern and dimensions of the sheets differ not only among manufacturers, but also within the company for different product lines.

Compliance with the parameters and tolerances affects the quality of the roof - the absence of gaps between the sheets, the plane of the roof.

When accepting products, check:

- the depth of the pattern (the wave height of the metal tile) - the distance between the parallel ridges, the tolerance is 1 mm;

- profile step - the interval between adjacent vertical ridges, deviation up to 1 mm;

- the full and useful width of the sheet of metal - the manufacturer has the right to set the parameters himself, a difference of 5 mm is permissible;

- crescent shape of sheets - bending relative to the center line, 2 mm per 1 meter of sheet length or 9 mm for the entire sheet is allowed;

- oblique cut - should not reduce the length of the sheet less than the stated size;

- the length of the metal tile, which cannot deviate by more than 2 mm for products up to 6 m and 6 mm for sheets longer than 6 meters;

- diagonals that cannot differ by more than 2 mm.

By agreement with large customers, the manufacturer can set other product characteristics

Description of parameters

Full length - distance between opposite end edges. On sale there are products with characteristics from 450 to 8000 mm. The parameter affects the convenience of work and material consumption or the need to overlap the sheets by the wavelength of the metal tile (steps).

Under useful length understand the distance that covers one sheet after imposing an adjacent horizontal row on it. Knowing the characteristics, you can calculate the number of rows of sheets required for the roof.

Full width called the distance between the vertical edges. It is convenient to work with elements up to 120 cm - there is enough scope for a person's hands, so manufacturers try to fit into this size. Sheet metal products are produced with standard dimensions of 1000, 1250 and 1500 mm, the most popular of which is 1250, from which metal tiles are made.

Working or useful width of a metal tile always less than full, since the sheets are laid with an overlap, excluding the flow of water. Some of the products are made with side locks. This reduces the overlap width and saves material.

Wave step - the distance between the longitudinal ridges - taken into account for the correct filling of the crate, on which the lower plane of the sheets rests.Self-tapping screws are screwed in the same place, so there should be no gaps and voids under some structural elements.

Wavelength or steps is determined by the distance between adjacent elements of the tile pattern. The manufacturer has the right to determine this parameter himself and depending on the "pattern", the step of the wave is very different.

The characteristic is important when designing a roof for two reasons:

- sheets cannot be cut along the ridge;

- each recess must rest on the lathing.

Knowing the wavelength, errors are avoided in the manufacture of the base for the finishing layer of the roof.

Step height - the distance between the deflection and the top of the ridge. The larger the parameter, the better the sheet resists external loads. Size is important when purchasing additional elements, as they must be of the appropriate size.

Sheet thickness for different products, it can vary from 0.35 to 0.7 mm. Products with a thickness of up to 0.45 mm are not distinguished by high strength and durability. In this range, the manufacturer does not spend money on high-quality galvanizing, limiting himself to a consumption of 140g / m². The best protection is possessed by sheets from 0.5 mm, which take up to 275 g / m² of zinc.

Large products are produced in the range of 0.48–0.55 mm, which is enough to ensure the strength and durability of the roof.

Capillary groove stamped along one edge of the sheet. It serves to remove moisture formed during condensation.

During installation, a wave with a capillary groove is covered with the next sheet. The location of the element depends on which side of the roof to start laying the sheets on.

Product range of major manufacturers

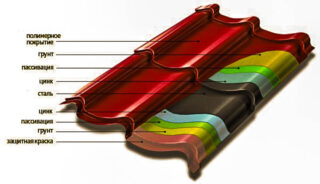

Manufacturing of high-quality metal tiles is a technologically difficult process including:

- sheet metal rolling and zinc coating are carried out at the factories of raw material suppliers;

- passivation - applying a protective coating over the galvanized layer;

- spraying paint that determines the color of the finished product;

- profiling - giving a sheet of a given shape;

- cutting and packaging of finished products.

Only large manufacturers can perform all stages in a quality manner, therefore, before buying, you need to familiarize yourself with the certificates.

Experts identify 7 large companies in Russia, each of which has several factories in different Federal Districts.

The products of different companies may differ in the size of the metal sheet, color, shape and dimensions of the additional elements. Often the products are not interchangeable, so it is advisable to purchase the entire roof kit from one vendor or manufacturer.

Grand Line

The company owns 9 factories and manufactures products in 7 lines, the palette of colors is 15 shades.

Positive aspects: low price, durability, fast delivery of large quantities. Among the negative sides, a high-quality protective coating is not always distinguished, and the surface of additional elements is painted only in white and brown.

Table of models and sizes of metal tiles Grand Line.

| Brand | Overall / useful width, mm | Step step, mm | Wave height, mm | Step, mm | Min / max sheet length, m |

| Quadro Profi | 1159/1080 | 350 | 25 | 20 | 0,45/8 |

| Classic | 1180/1100 | 350 | 23,5 | 21 | 0,5/6,5 |

| Kredo | 1190/1110 | 350 | 28,5 | 20 | 0,5/6,5 |

| Kamea | 1180/1085 | 350 | 30 | 20 | 0,5/6,5 |

| Kvinta uno | 1210/1150 | 350 | 20 | 20 | 0,5/6,5 |

| Kvinta plus 3D | 1210/1150 | 350 | 20 | 20 | 0,47/6 |

| Kvinta plus | 1210/1150 | 350 | 20 | 20 | 0,6,5 |

Products are available in most cities, as the manufacturer is actively developing a network of regional offices.

RUUKKI

Finnish company, part of the SSAB steel concern.

A popular type of product on the market.

| Brand | Overall / useful width, mm | Height, mm | Min / max length / mm |

| MONTERREY | 1180/1100 | 39 | 450/8000 |

| FINNERA | 1190/1140 | 52 | 660/6850 |

| ADAMANTE | 1170/1125 | 55 | 850/6050 |

The step and height of the steps are the same for all products and are 350 and 14 mm, respectively. The manufacturer gives a guarantee for products from 30 to 50 years.

Metal Profile

Produces six types of metal profiles:

- Lamonterra X;

- Lamonterra;

- Monterrosa-S;

- Tramontana-S;

- Montecristo-S;

- Maxi.

The sheets, depending on the modification, differ in all important parameters:

- length - 0.5–8 m;

- useful width - 1100-1155 mm;

- step of steps - 350–400 mm;

- wave height - 39-50 mm;

When buying, they buy tiles and additional elements suitable for one series.

Products of other brands are popular: Interprofile, Stynergy, Poimukate, Pelti Ja Rauta. In total, there are about 40 factories in the country; when buying, one should focus on the availability of their goods in the home region.

Expert advice on selection

Most of the factories buy finished rolled metal rolls with a zinc layer already applied. The quality of the paint application and the adherence to dimensional tolerances are the responsibility of the tile manufacturer.

Modern equipment for profiling and painting is owned by large companies, it is their products that experts in the field of construction advise to buy.

European brands use their own raw materials, which adds confidence in the quality of metal tiles.

Zinc coating thickness

During the forming process, different parts of the sheet are stretched to a different extent, so the thickness of the zinc protection layer changes relative to the corresponding parameter for the raw material. In areas subject to the greatest deformation, the layer can be very different (thinner) from the initial value.

Because of these changes, the accompanying documentation does not indicate the thickness of the protective coating, but the amount of zinc covering each square meter of the surface.

Experts do not advise purchasing products with a value less than 270 g / m², this will ensure the preservation of the layer thickness after stretching during rolling.

Type and thickness of the protective polymer coating

As a primer, polyester, epoxy, polyurethane and acrylic compounds are used, applied with a thickness of 5 to 30 microns. The front side is covered with finishing enamels on a polyester, polyurethane or polyvinylidene fluoride base with a thickness of 18-40 microns. The reverse side is painted with polyester, epoxy or epoxy-polyester enamel.

The total thickness of the polymer coating cannot be less than 25 microns. GOST allows a deterioration of the parameter by agreement with the customer, but such products rarely last more than 5 years.

Plastisol is applied with a layer of 100 to 500 microns, taking into account the thickness of the soil.

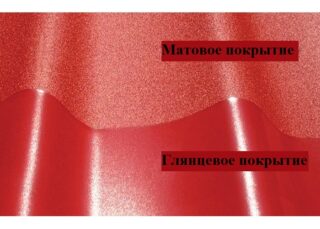

According to the surface structure, 4 types of products are installed:

- smooth;

- textured;

- wrinkled;

- embossed.

In appearance, a matte or glossy surface is distinguished.

All surfaces, except for glossy smooth surfaces, are susceptible to accelerated contamination by dust and other suspended particles (soot, etc.). It is not always possible to clean the roof physically, therefore it is better to choose a smooth metal tile for installation.

Why is it important to choose the right length of sheets

Manufacturers produce metal tiles up to 8 meters long. This is convenient if the roof slope is suitable for these parameters - a continuous strip has no joints, into which water may enter due to the lack of overlap, it saves money.

At the same time, for unloading, lifting a long sheet to the place of installation, 3-4 people will be required - one loader for 2-2.5 running meters.

Gusts of wind put a heavy load on a sheet with a large surface area. During operation, a long piece of metal tile can be pulled out of the hands and damaged. Cases of sheet breaks are not uncommon. Storage requires a large room, which may not be available when building a private house.

Installers advise purchasing sheets from 4 to 5 meters long, they are easy to move and install.

In large cities, on request, it is possible to purchase sheets of any length in the range from 2 to 8 meters. Cutting is often done free of charge.

For roofs with a complex surface (hip, hip, half-hip), it is advisable to entrust the calculation and cutting of the material to a specialized company, since self-cutting can result in damage to the material and a large amount of waste.