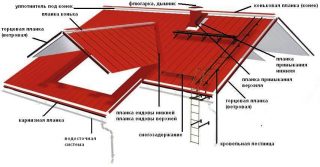

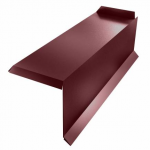

To cover the roof, roofing material and additional elements are required. One of them is an end strip for corrugated board or metal tiles. It is not just a finishing element, but a functional detail that redistributes the wind load.

What is an end plate

Steel sheet flooring is laid on a sparse lathing or on a counter-lattice... Under the decking is formed roof space... The air circulating here prevents moisture accumulation, but the space itself needs protection.

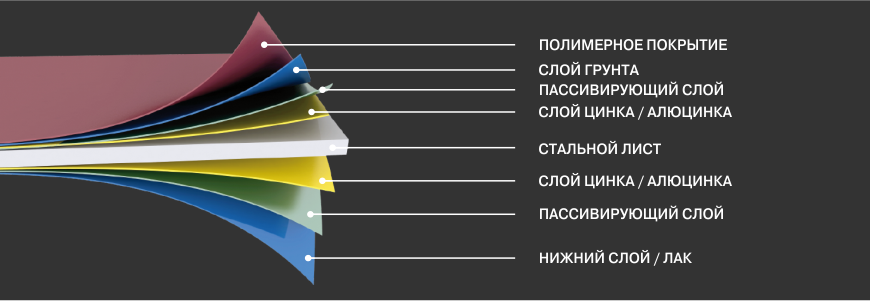

What is it made of

An end strip is made of the same material as the main flooring. But since it is subject to more stress than the roof, it can be more protected.

- The basis is steel with a thickness of 0.45 to 0.5 mm... Choose a bar based on the thickness of the base sheet.

- The element is coated on both sides zinc layer... It protects steel from contact with water and oxygen and prevents rusting.

- Passivation layer also applied on the front and on the seamy side. It protects the metal from corrosion.

- Soil layer improves adhesion.

- The last layer is polymer decorative coating... Protects against mechanical damage and ultraviolet radiation.

Color palette additional elements match the palette of metal tiles or corrugated board, so it's easy to choose the appropriate shade.

Specifications

- A sheet of steel with a thickness of at least 0.45 mm serves as a blank. This is sufficient for the expected load.

- The zinc layer is at least 275 g / sq. m. According to GOST standards, the minimum coating thickness is 90 g / sq. m. However, this is not enough for the end plate.

- The polymer coating is selected based on the expected operating conditions. So, polyester is intended for mid-latitudes and regions without heavy rain. If the climatic conditions are more difficult, it is better to take a material with a PVC coating. In the southern regions and in elevated areas, only pural provides sufficient resistance to ultraviolet radiation.

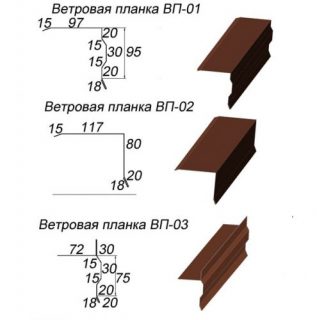

Dimensions (edit) wind bar for corrugated board depend on the type of product. Models with dimensions are considered standard. 40 * 60mm and 90 * 150mm... The fragments are 2 meters... However, the usable area is actually less, as the elements need to be stacked with an overlap of 5-10 cm... Usually, narrow strips are installed on flat roofs, and wide ones on steep slopes.

Complex shaped moldings have other dimensions.

Varieties of end strips

There are 2 main types of elements: classic and segment.

Classic end strips are used for any type of corrugated board and almost all types of metal tiles. The element looks like a corner with curved edges. The usual length is 2 m. There are several models.

- Figured - both sides of the plank are embossed. It not only looks the most aesthetically pleasing, but is also more durable, since it has stiffening ribs.

- Flat - has the same dimensions, but its surface is flat.

- Wide - with flat sides. It is distinguished by its large size. Such an element is fixed under the highest profile of a metal tile or a high counter-lattice.

Segment strips are more complex in configuration. The element tapers upwards, not only the side but also the end edges are bent. This model is designed for modern high ridge profiles. Segmented end strips follow the relief of the metal tile and look more voluminous.

Installation features

The wind corner for the profiled sheet is mounted after installing the roof covering... There is a difference in the step-by-step installation scheme for the classic and segment models.

The classic version is attached So:

- the planks are laid on the end from the bottom up - from the eaves to the ridge, with an overlap of 5-10 cm;

- the elements are aligned so that the bottom edge with the roof is a straight line;

- after alignment, the plank is fixed with self-tapping screws in the side and upper parts in increments of 50-60 cm.

The segment strip is attached in the following way:

- elements are installed from bottom to top;

- align to the bottom;

- you need to fasten it on the side, only in overlap places;

- the second self-tapping screw is screwed into the end of the formed "step".

For fastening, you need to take galvanized screws.

Tips & Tricks

When installing additional elements with your own hands, it is recommended to perform the following the requirements:

- for fasteners it is better to use self-tapping screws with wide heads;

- if you have to cut a bar, you need make a longitudinal cut with scissors for metal, and a transverse jigsaw;

- self-tapping screws no need to twist too much, otherwise, over time, swelling may appear here.

If the element was damaged during installation, it must be replaced or cut by removing the damaged area.