The advantages of sheet materials make them popular in private and industrial construction. DSP slab is a durable and technological material used for the construction of frame buildings, as well as for the manufacture of non-bearing structures.

Purpose of products

CBPB has been used in construction for over 50 years. During this time, the main methods of application have been identified cement particle boards. Flame retardant, biostable material with the correct application technology allows you to make:

- blind areas and paths;

- permanent formwork of the foundation;

- facade decoration;

- subfloors and filing of floors;

- cladding of internal walls and partitions;

- filing ceilings;

- base for the topcoat of flat and pitched roofs;

- ventilation ducts.

Plates with a decorative layer make it possible to do without finishing the outer walls.

Material description

Cement particle board is sheet extruded materialmade from wood filler and binder based on different types of cement. Depending on the composition and manufacturing technology, the entire range of DSP panels has similar consumer qualities.

Types of plates, manufacturing technology

Depending on the manufacturing technology, the DSP sheet may have a different composition and characteristics.

There are three main types of products: fibrolite, xylene and wood concrete.

Fibrolite

CBPB made of fiberboard is a product, the peculiarity of which is composition of raw materials:

- Portland cement grade not lower than M400;

- wood shavings from 30 to 50 mm long from spruce, pine or fir;

- chemical additives - calcium chloride, liquid glass, lime, aluminum sulfate.

The addition of hardwood shavings is allowed, if this does not affect the characteristics of the DSP. Long fibers allow to obtain a strong material that resists bending loads.

According to the current GOST 8928–81, produce products three brandswhich correspond to the density of the material:

- F-300 - 250-350 kg / m³;

- Ф-400 - 350-450 kg / m³;

- Ф-500 - 450-500 kg / m³.

Dimensions (edit) CBPB made of fiberboard:

- length 2400 or 3000 mm;

- height - 600 or 1200 mm;

- thickness - 30 (except for grade 300), 50, 75, 100 or 150 mm.

The F-300 brand is used as a heat-insulating material, and the F-400 and F-500 as a structural, heat-insulating and sound-insulating product.

Using fiberboard plates, they make three-layer structured insulation panels (SIP). Fiberboard sheets are outer layers, between which polyurethane foam or foam boards of various thicknesses are glued.

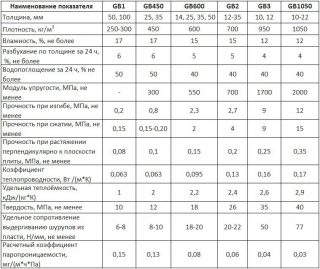

Foreign manufacturers have adopted a different marking:

- GB 1 - low density slabs (250–450 kg / m³);

- GB 2 - products of medium weight (600–800 kg / m³);

- GB 3 is the most durable grade with a density of 1050 kg / m³.

GB abbreviation stands for Green Board - green, i.e. ecological product.

Strict size for GB slabs is not specified, manufacturers themselves have the right to determine this indicator. It is convenient for repairing small rooms, as it allows you to select sheets of the required size and get less waste.

High density products, regardless of the manufacturer, can be produced heterogeneous sheet structure... The inner layer is often made less dense with a coarse filler, and the surfaces are made from a durable composition with fine sawdust.

Xylolite

Xylolite - white or yellowish material, similar in properties and characteristics to wood-cement and gypsum-wood boards. The product belongs to lightweight concrete. Sometimes other names are used - dew or bischolite.

For manufacturing use small sawdust or flour, grinding dust of woodworking industries, sometimes bran - waste of flour mills.

Depends on the size of the fraction outer surface structure - the smaller the filler particles, the smoother the sheet is. Top quality products are free of bark and debris, which increases the strength of the material.

The binder of xylene is Sorel cement - caustic magnesite dissolved in magnesium chloride, magnesium sulfate or iron sulfate.

All components are natural materials and do not emit radiation.

For coloring organic or inorganic dyes, sometimes of different colors, are introduced into the mixture to create a contrasting pattern.

By changing the composition of raw materials, xylolite of different properties and characteristics:

- density - 900–1400 kg / m³;

- thermal conductivity - 0.2 - 0.5 W / (m * ° C).

Under shock loads dents appear on the xylene, but the sheet does not collapse. The material is resistant to acids and alkalis, oils, salts, organic solvents.

Xylolite ne burns, but only charred under the influence of open fire.

Accelerated corrosion occurs in the places of contact between xylene and metals, therefore, during the installation of structures, it is necessary to ensure the insulation of materials.

When wetted with water, the slabs do not become slippery, which has a beneficial effect on consumer properties.

In addition to the traditional DSP use, made from xylolite:

- bases for pouring floors in railway cars;

- columns and wall beams;

- stair steps;

- plates for mosaic floors;

- frames for mirrors and paintings;

- lining of chimneys, grotto vases, gazebos.

The material is paintable.

Products bischofite-based used in treatment rooms for wall decoration.

Geometric dimensions sheets: length 1200–3600 mm, width - 60–1200 mm, thickness of xylene cement-bonded particle board - up to 100 mm.

Arbolit

Material highly absorbent, therefore, it is unacceptable to use it for construction if the humidity exceeds 75%. In damp rooms and outside buildings, the slabs must be covered with a moisture-proof finish.

By purpose, the slabs are divided into heat-insulating and structural-heat-insulating.

- dense,

- porous,

- large pore.

The higher the density, the stronger the product.

Specific gravity material ranges from 250 to 950 kg / m³.

Arbolite plates used for the manufacture of:

- thermal insulation;

- SIP panels;

- non-bearing, self-bearing and bearing walls and partitions in low-rise construction;

- thermal liners for walls;

- permanent formwork.

Coefficient of thermal conductivity depends on the density of the material and can be from 0.07 to 0.19 W / (m * ° C) for dry operating conditions. For calculating the thermal conductivity of external walls, parameters from 0.11 to 0.27 W / (m * ° C) are used.

Recently, the production of wood concrete slabs has been gradually reduced due to low strength. They are replaced by DSP boards manufactured in accordance with GOST 26816-2016.

Features of use

Application options for DSP boards depend on material characteristics.

The first important parameter is thickness... For cladding partitions, DSP with a thickness of 8 to 24 mm is suitable. Columns and crossbars are clad with material from 8 to 16 mm, and the outer walls from 10 to 24 mm.

The base for the floor screed and the attic of the house is made of moisture-resistant CSP 12-24 mm. Slabs of 20, 24 or 36 mm are laid under the subfloor. For window sills and steps, sheets of 24 or 26 mm are suitable.

Installation rules

The installation methods depend on the expected operating conditions, but the following regulations always observe:

- cutting carried out with the same tools as wood, it is undesirable to use expensive hacksaws, since the teeth are quickly ground off from the cement;

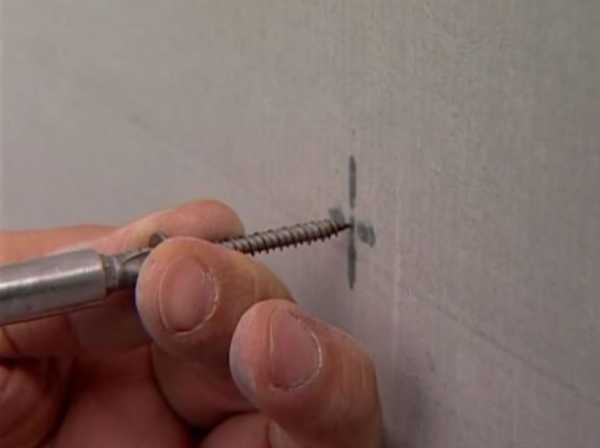

- fastening carried out with nails or self-tapping screws, the second option is preferable, so it provides a snug fit;

- under the head of the self-tapping screw put the washer - this will prevent the destruction and pushing of the plate with great efforts applied when twisting the hardware;

- drilling carried out with hand or electric drills, ceramic drills with a carbide tip are used.

Crate for fixing plates up to 50 mm thick, they are made in 60 cm increments; for thicker products, the step can be increased up to 100 cm.

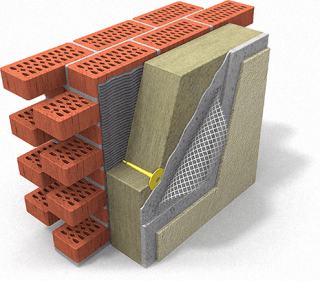

Wet facade finish

- With glue and wide-headed dowels the plates are fixed in the wall, be sure to take into account the weight of the DSP, increasing the number of attachment points. Work begins from the bottom of the wall, the material is fastened in a checkerboard pattern.

- The surface is protected reinforcing mesh, which is glued with cement-based mounting glue.

- After the first layer has dried, carry out plaster and then putty.

- Finishing consists in painting or installing siding.

When arranging floors CBPB is laid on a cement-sand screed. Fastening is carried out with dowels. Gaps of 3-4 mm must be left between the plates, which are filled with cement mortar.

When building warm roofs CBPB is used as waterproofing and wind insulation. The material is mounted between the rafters, screwing it to the inside of the sheathing.