For the construction of a building, an ordinary block and elements of a special shape for partitions, ceilings are required. They produce models designed for arranging stiffening belts. It is much more convenient and profitable to use such blocks instead of ordinary aerated concrete.

U-shaped blocks of aerated concrete

Such a device is required in the construction of any residential building made of foam concrete.

The gas block does not have the lowest bearing capacity. However, the material unstable to bending load: from the slightest displacement, cracks appear inside the blocks. The likelihood of such loads is especially high at the junction of the foundation and in the overlap area... It is important here to distribute the load as evenly as possible in order to avoid movement.

U-block reinforcement belt solves this problem. The stone is laid instead of the usual one, reinforcement is placed inside, tied together to form a single distribution contour, and poured with concrete. The structure, reinforced in this way, easily withstands additional loads and prevents cracking and deformation of the walls.

Can I do it myself

In production, a U-shaped aerated concrete block is obtained by pouring the initial mixture in a form of a certain configuration... However, make elements like this you can do it yourself.

- The U design can be simply cut from finished block... A depression and the desired wall thickness are marked on the stone, then the necessary cuts are made, and the excess material is knocked out with a hammer. The method is simple, since aerated concrete is very easy to saw and cut. but material consumption is very highas sawn blocks are usually difficult to use.

- Another method is gluing U-shaped bricks from flat plates the desired size and shape The latter are also usually cut out of the finished gas silicate. Then the blanks are glued together using a special glue for aerated concrete. The glue is very durable, so there is no need to worry about damaging the block.

The second method is more time consuming, but allows you to rationally use material and reduce costs.

Self-made structures are more than justified when they mount fixed formwork, protective structures.

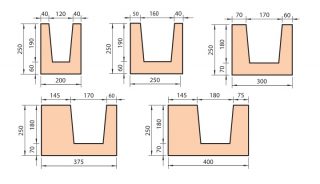

Design features and dimensions

- width - 20, 25, 28.8, 30, 36.5, 37.5, 40 cm;

- height - can only be 20 and 25 cm;

- Wall thickness - 7 and 14.5 cm.

The wall thickness is measured at the top. This is due to the fact that the recess can have different shapes: regular rectangular and with beveled walls tapering from above. In addition, the wall thickness can be the same or different. In the second case, it becomes possible to shift the load and distribute it differently.

Characteristics of U-blocks

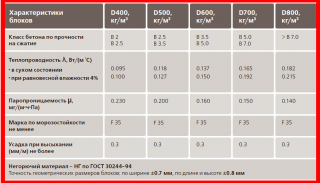

- Density - depends on the total number of pores in the material. U-blocks are made of concrete grade D400, D500, D600. Foam concrete with a porosity of more than 75% is not used for lintels, since it is not strong enough.

- Strength characteristics related to density. For a product made of D600, they are higher: the material withstands the load in 4.5 MPa... The D400 scores are much lower - 1.5 MPa. The first option is taken to reinforce the belt under the ceiling. The second is more often used for the construction of permanent formwork.

- Thermal conductivity - also related to porosity. The higher it is, the better the aerated concrete retains heat. The average is 0.114 W at 1 degree Celsius.

- Vapor permeability – not less than 0.2 mg / m / h / Pa... The material allows you to remove excess moisture from the indoor air to the outside.

- Frost resistance - the maximum possible indicator is 100 complete freeze-thaw cycles, therefore, aerated concrete is not used in northern latitudes.

- Water absorption - fluctuates from 6 to 16%. The parameter depends on the manufacturing method. Autoclaved aerated concrete is stronger, but has open pores, so it easily absorbs moisture. The use of the material is still justified, since it gives off moisture as easily as it absorbs.

The lower the density of aerated concrete, the less durable the material. Therefore, the blocks are not made of concrete below the D400 grade.

Application features for armored belts and attic floors

U-shaped aerated concrete blocks are laid in the last row before overlap or mauerlat... The number of pieces is calculated taking into account the weight of the structure. Such a belt allows you to evenly distribute the load and avoid bends and displacements. The technology is simple.

- U-blocks are placed on glue or cement mortar. Stones it is important to dock very tightlyso it's better to use glue.

- Assemble the reinforcing frame... To do this, take steel rods with diameters of 0.02% of the wall thickness. The rods are tied with a knitting wire, an overlap of 20 cm remains.

- The frame is laid in the gutter... A large number of bars should end up at the bottom of the frame.

- Fix the reinforcement with spacers... The walls of the gutter are moistened.

- Fill the furrows with concrete mortar... Pierce the material with a knife or trowel to remove gas bubbles. Then fill the level of the solution, and remove the excess. The surface of the row should be perfectly flat.

The solid surface under the last row of U-blocks must be at least 20 cm.

Using U-Blocks as Jumpers

- The block is placed horizontally and poured with concrete. In this case, the fittings are almost never used. Then the finished product is moved to the desired location. Not the most convenient way, because after pouring with concrete, the block becomes very heavy. To move such a jumper, one has to resort to special equipment.

- Y-blocks can install in plank formwork, installed above the opening. It is recommended to strengthen door and window openings, so that reinforcement is placed inside the block. Then the grooves are poured with concrete. After the concrete has dried, the formwork is removed and construction continues.

It is important to monitor the correct position of the jumper: after solidification, it is extremely difficult to change it.