Installation of roofs with a steep slope prevents them from being pushed through by snow masses, but does not reduce the problem of their avalanche-like descent with a large accumulation. Installation of snow guards on the roof made of corrugated board ensures safe operation of the building for people and engineering structures in all weather conditions. In order to correctly and reliably fix the snow holder on the profiled sheet, you need to understand the types, device and procedure for installing these structures.

What is a snow holder

Snow holders are metal products designed to act on snow masses in order to prevent an avalanche from falling from a pitched roof. The devices consist of a body, working bodies and mounting brackets.

According to the principle of operation, snow holders for corrugated board are divided into the following types:

- Barrier. Designed for snow retention in large volumes before they melt under the influence of the sun, air temperature and roof. It is allowed to install such elements only on top of roofs with powerful truss systems.

- Cutting. The technology of their work does not consist in the accumulation of masses, but in their transmission in small quantities. Large layers, passing through the working bodies, stratify into thin plates that do not threaten communications and human health.

Correct installation of snow guards on a corrugated roof requires careful analysis of the associated conditions and the manufacturer's instructions.

Installation features

The metal profile laid on the roof is practical, strong enough and protected from moisture. At the same time, the coating is designed for a certain vertical load, and polymer spraying is easy to scratch.

Fastening the snow catchers to the metal profile provides a solution to the following problems:

- Stopped masses melt, water runs in small volumes into the gutters, goes into the sewer, without eroding the walls and blind area.

- When passing through the cutters, the snowdrifts break up into small fragments that do not pose a danger to people and structures near the house.

- Barriers slow down the speed of snow movement along the profile enough to melt the ice crust. This preserves the integrity of the polymer coating.

- The devices protect the gutters from deformation, preventing snow masses from slipping there.

It is advisable to buy snow holders at the same time as sheets and additional parts, preferably from one manufacturer. This will guarantee the complete match of the color of the products and the consistency of their sizes with each other.

Calculation of the number of structures on the roof

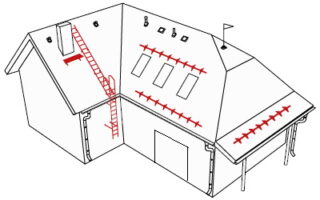

The options for the location of products can be different - solid stripes or staggered, but in all cases there must be full coverage around the perimeter of the building.

It is necessary to attach snow holders to the corrugated board over the following places:

- entrance doors;

- paths under pitched roofs;

- balconies;

- panoramic windows;

- parking lots;

- children's playgrounds;

- flower beds;

- elements of landscape design.

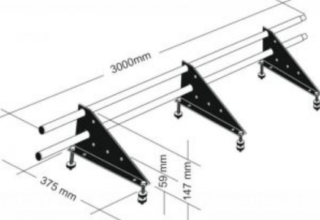

The distance between the elements is selected based on the steepness of the slopes and the amount of precipitation in the winter season.It is customary to retreat from the edge of the roof by 50 cm, and then place barriers with an interval of 250-300 cm between parallel devices. When designing, you need to draw up a diagram and insert into it the standard sizes of snow holders for roofing from corrugated board. Next, the calculation is done, the fractional values are rounded up.

Installation methods

When compacted and saturated with moisture, the drifts on the roof become heavy, creating high pressure on the roof covering and rafter system. Proceeding from this, it is allowed to fix the strips only on reinforced type hardware. It is allowed to screw it through the metal onto the crate. The hardware should go through the base, and the hole should be located as close as possible to the central axis of the rail.

Each bracket must be fixed with at least three self-tapping screws. If this is not provided for by the design, it is recommended to make additional holes, reinforcing them with washers.

Fasteners violate the integrity of the roofing, therefore, roofing screws with a press washer and a rubber seal are used. In the places of attachments, the crate is made thicker, more firmly attached to the rafters.

Preparing for installation

The preparatory stage must be carried out in advance in order to have everything you need at hand at the time of installation.

For work you will need:

- screwdriver with drilling mode;

- level;

- roulette;

- glue gun;

- mallet;

- self-tapping screws;

- sealant.

Safety issues should be considered initially. Installation must be carried out with insurance, in a helmet, glasses and gloves. Fencing and warning signs should be installed around the building.

Mounting instructions

Snow holders can be attached to the roof in whole or in stages. It depends on their device, size and skill of the master.

For tubular and log models, the side brackets are first screwed on, and then the working bodies are inserted into them. The pipes are fixed in the holes with studs or bolts.

Corner barriers have a one-piece structure. Therefore, they are installed entirely. Their weight is insignificant, but the windage is large, which must be taken into account in advance. Following the initial marking, one bracket is screwed on, after adjusting the second, and after the final alignment, the rest of the hardware is inserted and tightened.

Yokes are more often used as additions to horizontal slats. They are hooks or teeth on a platform, staggered along the entire roof or pointwise between solid barriers.

Lattice devices are attached directly to the edges of the roof. Based on this, reinforcement of the overhangs is required so that they can withstand additional snow load. In such cases, overhangs and crossbars are attached to the rafters to strengthen the edges of the roof.

On a limited budget, the perimeter of the roof does not close completely. Fences are installed only over the most important objects from the point of view of safety. With a slope length of more than 500 cm, the planks are mounted in several rows. Over time, the holes can be closed during routine roof maintenance.

Problems when installing snow guards

The list of problems and the reasons for their occurrence when installing snow guards:

- the brackets are torn off - the screws are screwed only into the profiled sheet or into the edge of the batten rail;

- leaks at the points of attachment of the snow protection - ignoring the thermal washer, too strong or weak tightening of hardware;

- fasteners fail - low quality products, violation of installation technology;

- snow masses break through the snow - incorrect calculations, saving on protection;

- systems do not cope with their functions - poorly thought out installation scheme, products of insufficient size or strength.

When planning the installation, it is better to focus on the critical volumes of snowfall.A small overpayment will help keep the building from collapsing.