Facades and internal walls of buildings are sheathed with thin facing boards obtained by processing wood. The wooden lining has fasteners in the structure, so a continuous decorative layer without cracks is obtained. The standard variety of material has a reasonable price. The room maintains a comfortable microclimate.

- Description of finishing material

- Applications

- Varieties and sizes of profiles

- Standard

- Euro lining

- Calm

- Softline

- American

- Block house

- Landhouse

- Lining classes

- Extra

- Class A

- Class B

- Class C

- Features of spliced lining

- Wood species

- Conifers

- Deciduous

- How to choose material

- For outdoor work

- For interior work

- When should you choose plastic or MDF

- Installation rules

- Installing the frame

- Installation of lining indoors

Description of finishing material

Manufacturers subdivide products based on:

- humidity - in its natural state and dry (10 - 15%);

- dimensions and geometric shape;

- grade of wood.

Produce lining from any kind of wood, while the characteristics of raw materials must correspond to the standard indicators of the finishing material in accordance with GOST.

Applications

Use cases various types of lining:

- in residential premises without a sharp temperature drop (-5 - + 30 ° С), with low air humidity (up to 60%);

- for the outer walls of houses, summer cottages, offices, recreation areas;

- inside saunas, baths (linden), in steam rooms (alder) at temperatures up to + 120 ° С and atmospheric humidity up to 100%;

- for finishing unheated balconies, loggias, attics, technical rooms.

The material is mounted on walls and ceilings, columns and beams are sheathed with it. Thin boards are taken for interior work, and massive ones are used on the facade.

Varieties and sizes of profiles

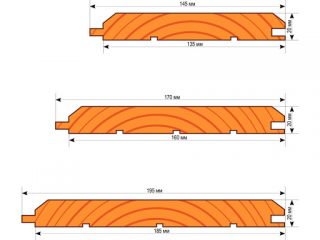

Generalized sizes of different types of panels:

- material thickness varies from 12 to 25 mm;

- length is 0.6 - 3.0 m;

- the width of the lining is up to 160 mm;

- the height of the pins is 4 - 8 mm.

Allowing errors from the indicated dimensions in width and thickness - 1 mm, the length of the strips - 5 mm, the height of the spike should not differ by more than 0.5 mm.

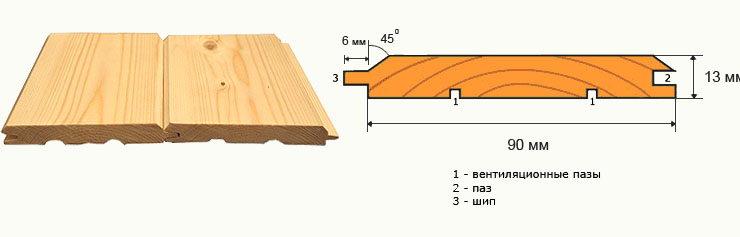

Standard

It is the basic variety. Short panels are cheaper because there are more possibilities for their production (sampling of areas between knots).

Description of the species:

- the section forms a trapezoid with beveled edges at an angle of 30 °;

- grooves are formed on the back side to compensate for changes in dimensions;

- lateral surfaces are provided with recesses and projections (tongue-and-groove connection).

The surface is uniform with small strip grooves along the joint line due to the oblique shape of the edges. The spike is made smaller than the mating groove so that the elements can move during shrinkage after installation.

Euro lining

Eurostandard DIN 68126.86 normalizes product indicators:

- moisture content of raw materials;

- geometry of the finished product;

- quality of surface grinding.

Eurolining differs from ordinary panels in high quality, perfect smoothness, the number of channels on the back.

Calm

Release wide range of colors and shades:

- light boards installed in an upright position visually raise the ceilings, increase the volume;

- dark colored panels mounted sideways bring the wall closer in long rooms.

Externally, the elements are produced in the form of imitation of a bar, the elements are thickened up to 2.5 cm.

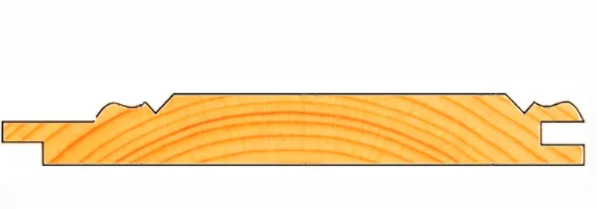

Softline

The finish does not look as massive as when installing profiles with imitation of a bar. Products are produced with widened spike and groove... On the back there are drainage and compensation channels. The cost depends on the length of the elements and the grade of the material.

American

Product Features:

- from one end, the thickness is 22 - 28 mm, from the other - 14 - 20 mm;

- the width of the boards is 140 - 190 mm.

The planks are mounted with an overlap, obtaining a herringbone effect. In this case, moisture flows off the wall, and does not penetrate into the layer.

Block house

Release varieties:

- one-sided;

- double-sided;

- standard one-break;

- two-breaking (wider lamellae).

Produce material by type "Square in a circle", the central section of the log is used for sawing into boards or bars, and a type of Block House is obtained from the semicircular edge parts.

Landhouse

Expensive products are produced with a curly profile of complex shape... They are used in the cladding of elite premises. Double-sided boards are used when installing internal partitions.

Front surface treatment methods:

- milling a longitudinal pattern;

- processing on digital equipment for applying transverse relief;

- hot pressing for embossing on the plane of the texture of wood.

The material effectively resists wetting and high temperatures, therefore it is suitable for wet rooms, for example, steam rooms, baths, saunas.

Lining classes

Check parameters:

- humidity;

- number, condition of knots, uniformity of color;

- the presence of wormholes and cracks;

- breed and direction of sawing.

Classes in Western countries A, B, C, in Russia are designated by 1, 2 and 3 grades. In addition to these gradations, there are Extra, Elite, Premium brands. Such lots are packed by manual inspection and visual inspection of the elements.

Extra

The cost of the lining is high, but even at this price it is difficult to produce it:

- boards made of pine or oak are available, since the breed does not rot and does not tend to form knots;

- spruce is prone to knotting, so it is difficult to choose the required dimensions of a wooden lining without defects from such wood, hence the price increase.

A dense, even board has a beautiful appearance, therefore the cladding is not spoiled with hardware... The material is installed using clamps. Treatment includes impregnation with an antiseptic, fire retardant, waterproofing agent.

Class A

The strips can be up to 6 m long. For the final finishing, putty is used, with which the problem areas around the knots are strengthened, the cracks are closed. Top covered with matte paints or colorless varnishes. When finishing, they combine light and dark tones, put the material of other classes.

Class B

The standards allow for the running meter of the lining:

- two knots or pockets;

- one superficial crack no more than three centimeters long or a chip;

- the presence of dull blurred spots is allowed,

Clapboard class B decorate non-residential rooms, technical rooms in the house, for example, storage rooms, corridors. It is recommended to putty knots, because when the material shrinks after a while, they can fall out, and cracks can increase in size.

Class C

Allowable defects at the rate per running meter:

- up to four pockets or knots;

- large cracks, irregularities, chips;

- improperly formed spike or groove;

- curvature of panels;

- ugly view of the front plane.

Sawed from the outside of the trunk, so the product can combine soft and hard layers of rings and core. During installation, you have to adjust the boards, which increases the duration of the work.

Features of spliced lining

Represents glued timber. The technology allows cutting of the ends on lamellas of a certain type, then the elements are glued together in order to gain the required strip length.

Description of spliced lining:

- the material is obtained without knots on the entire surface;

- adjustment of the picture within the panel is possible;

- low risk of warpage.

On the plane of the whole strips, stress appears during drying, temperature changes. In strips of pieces, such an effort is much less, so the geometric dimensions remain unchanged.

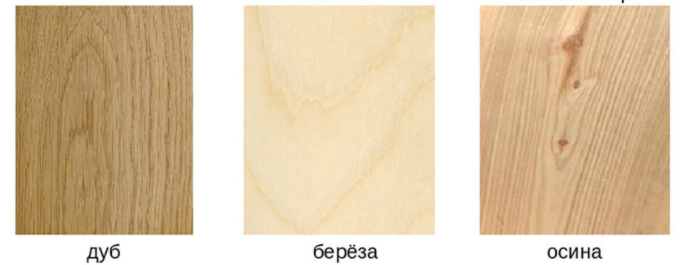

Wood species

To conifers include trees and shrubs with ruled, acicular or scaly foliage (needles).

Subdivision of such breeds:

- dark coniferous varieties - cedar, spruce, fir;

- light coniferous types - larch, pine.

Hardwood have lamellar foliage. Distinguish between small-leaved (black and gray alder, mountain ash), broad-leaved (hornbeam, maple, beech). Hardwood varieties include oak, ash, pear, acacia. Soft breeds with low density: aspen, birch, poplar, linden, willow.

Conifers

Lining is often made from larch, pine, spruce, cedar... The raw materials in the composition contain resins, so they are placed on the facade in order to increase the resistance of the layer to moisture and other negative factors. Resinous rock darkens less during operation.

Larch - durable material with high resistance to moisture, does not rot. Lining made of such a tree does not have to be antiseptic. Cedar does not heat up at high temperatures, therefore, the casing is used in baths. Pine is the weakest material, but it resists decay well.

Deciduous

The material is placed inside the house to create a comfortable microclimate. Hardwoods are beautifully cut, for example ash, beech, oak.

Qualitative characteristics:

- lime the board is considered healing, the lining is indispensable for saunas, baths, it releases useful components that stabilize the condition, strengthen health .;

- alder good soundproofing of the wall, belongs to the materials with a low fire hazard.

The cost of the lining depends on the value of the hardwood and the prevalence in the market.

How to choose material

Be sure to check material qualitypay attention to humidity... Underdried lining will warp over time, bend, so the coating will need to be repaired.

When choosing, take into account:

- the purpose of the walls, the location inside or outside the building;

- surface mounting method;

- room operation mode (high humidity, steam, high temperature);

- class and type of lining;

- wood species;

- cost.

Take into account useful lamella area without taking into account the locking protrusions, but they buy the goods taking into account the estimated width (from edge to edge).

For outdoor work

The cladding of the building is made with boards 2 - 2.5 cm thick. For low houses, narrow lamellas (100 - 120 mm) are purchased. I provide wide stripes for tall buildings. It is better to take longer boards so that there are fewer external joints and, accordingly, weak points.

Outside the houses are glazing antiseptics will last up to 7 years, acrylic paints will withstand up to 10 years of operation, oil compositions will lose their protective qualities after 5 years.

For interior work

The category of the room matters. For the utility rooms, they take material of a lower grade, and the living rooms are sheathed with high-quality clapboard.

For interior cladding choose material:

- alder is bought for the bathroom and kitchen, the material releases useful components for health and does not deteriorate from wet fumes;

- alder is also placed in the bedroom because of its good sound insulation, cedar is also chosen;

- in the corridors, on the balconies, pine is used, since the material firmly endures the action of negative factors.

For the choice, cost matters - living rooms and bedrooms are trimmed with expensive high quality breeds.

When should you choose plastic or MDF

Vinyl block house imitates sawn timber, and also produces decorative panels in the form of lining from MDF.

Vinyl Material Use Cases:

- if it is impossible to load the wall or ceiling structures (plastic strips weigh less);

- in the event of soil moisture acting on the wall, for example, in the basement;

- when the premises are classified as high fire hazard.

In bath complexes, saunas, MDF and vinyl are not used, because under the influence of high temperature the material releases harmful substances, for example, MDF produces vapors of formaldehyde resins.

Installation rules

Before work prepare the base. On the wall, layers of poorly attached plaster and other finishes are beaten off. To attach the lining to the glue, be sure to level the surface so that the protrusions on it do not exceed 2.0 cm.

Cracks are repaired with repair mortar. If hardware, for example, a dowel, gets into the crevice, it will soon loosen, which will affect the strength of the frame. The plane is primed with deep penetration compounds.

Installing the frame

The material is wooden lath section 40 x 40 or 40 x 30 mm. The elements will dry out several times, waiting for drying. You can take a galvanized profile, which is already ready for use.

Installation rules:

- begin to fasten the vertical racks from the corner, gradually moving towards the other adjacent wall;

- fixed to the base with dowels or self-tapping screws, depending on the type of wall material;

- apply a level, a plumb line, pull the cords to expose the elements in a single plane and coordinate vertical and horizontal;

- use staples and cross pieces from the g / cardboard fastening system.

At the top of the rack, they are connected with a strapping profile that reinforces the rigidity of the frame. The racks are mounted with a step of 50 - 70 cm, they are fixed in height after 40 - 50 cm.

Installation of lining indoors

Further order:

- clamps are placed on the central part of the strip or nailed to each vertical support;

- the second strip is inserted with a thorn inside the groove of the first element, knocked out with a hammer with a rubber head;

- fix the second board, install the following in the same way.

At the top, the last board is cut lengthwise so that it fits into the remaining gap. To decorate the inner and outer corners, use decorative corners, also do with the docking, start and end labels of the layer.