The basic material for many industries is rolled metal. The products include ready-to-use elements that serve as blanks for more complex structures. A huge range of rolled metal products is produced.

Definition of rolled metal

Profiles differ in size, configuration, metal consumption, which determines their purpose. The range is very wide: from steel circles and squares with a diameter of 10 mm to mine racks or parts for metal structures weighing several hundred kg.

Features of production

Rolled metal is produced using 3 main technologies. Preparation method significantly affects the properties.

- Hot rolling - the workpiece (ingot, strip, circle) is heated to + 1000 ° C. At the same time, the metal does not melt yet, but becomes malleable and ductile. In this form, the material is fed to the rolling mill. It passes through a system of rolls that shape the workpiece. This is how channels and pipes of large thickness, cheap and practical, are obtained. Disadvantage of the method: when hot steel comes into contact with air, it becomes scaled, and the surface of the part itself becomes uneven and requires additional processing.

- Cold rolling - the workpiece is fed onto rolls without heating, bent and stretched cold. The finished product is more expensive. Its shape, dimensions are much more accurate, the surface is even and smooth. In addition, the profiles obtained by flexible are stronger.

- Warm rolling - takes the middle position. Products are heated no higher than + 700 ° С. At the same time, the scale is less, and production does not become as expensive as cold rolled products.

Types of rolled metal and their application

Rolled metal products are classified according to a variety of criteria: shape, profile size, purpose - special or general, according to the method of surface treatment.

The rental is divided into flat and varietal. The first type includes sheet and coil steel, sheet metal and tape, the second - all the others.

Distinguish the following types of rolled metal:

- plain - stripes, flat hexagons, circles, squares;

- shaped - corner, channel, I-beam, rails and all other special products of a more complex shape.

Shaped rolled products are sorted by appointment... Products common purpose, such as a square, I-beam or Z-profile, and special - tractor springs, shaft mountings, car profiles.

The consumer most often encounters the following types of rolled metal.

- Armature - devices used to strengthen the structure and give strength to building structures. The wire reinforcement is produced - cold-rolled, and rod - hot-rolled. The rods can be used both individually and in the form of a flat mesh. Reinforcement is used to make volumetric frames for reinforced concrete structures of any kind.

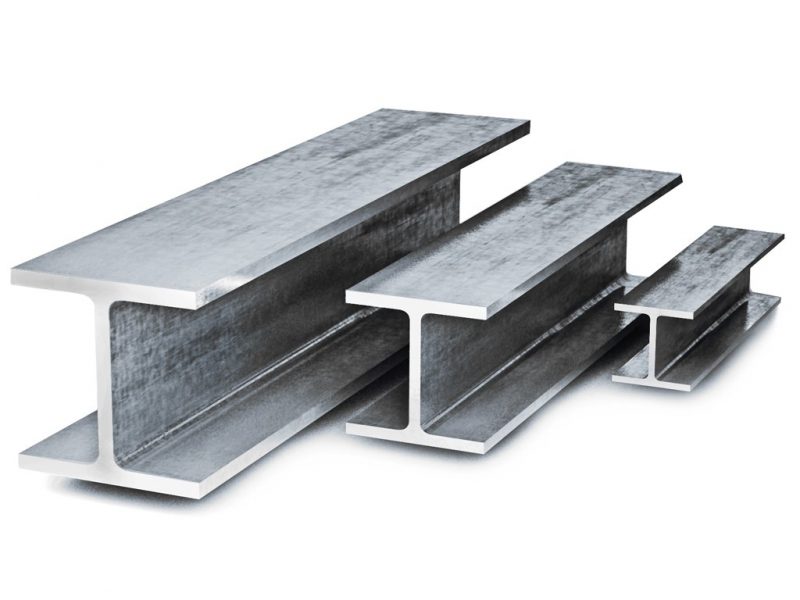

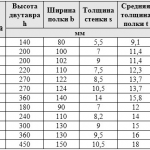

- Beam - I-beam. They represent a profile with an H-shaped section. Differs in high strength, resistance to loads of different types. Used in heavy construction: in the construction of bridges, the arrangement of oil wells.

- Square - a kind of long products.The calibration square serves as a blank for obtaining metal products: fasteners, cutting tools. Made of black steel, stainless steel.

- Sheet - a variant of flat metal products. It is used as an independent product - roofs are covered with galvanized sheet iron or tin, and as a basis for obtaining metal products of any kind. The determining parameter when choosing is the thickness of the sheet, and not the dimensions of the product.

- Band - an element whose length is significantly greater than its width. The thickness can be very different, since both simple products, like nuts, and complex mechanisms and heavy metal products, like an angle, channel, curved profile, are made from strips.

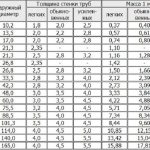

- Trumpet - the most famous high-quality rolled metal products. In terms of shape, sections are divided into round and profile - rectangular, square, oval, triangular. The configuration determines the purpose. Round and oval ones are designed for transferring liquid and gas, profile ones serve as a replacement for solid rods, since they have the same high bearing capacity with a lower metal consumption. Pipes are made in different ways. Hot-rolled and cold-rolled products are produced in mills from a solid billet. Electrowelded ones are made from a workpiece - a strip that is bent, twisted and welded.

- Corner - L-shaped profile. It is extremely widely used in construction: most frame structures are welded from a corner and a pipe.

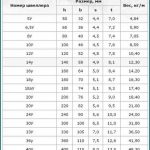

- Channel - U-shaped steel profile. During the construction of buildings, it serves as the main reinforcing material. Used in the construction of bridges, ramps, floors. Channels are produced in different lengths and thicknesses, with different sizes of shelves, as well as special ones - for the automotive industry, car building.

There are other types of rental as well. For example, a hexagon, which also serves as a blank for making a tool. Or a complex element like a spring. Its basis is a spring or a torsion rod.

Rolled metal weight

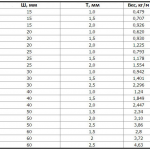

The mass of rolled metal is determined by its dimensions - the length, width and thickness of each element, as well as the density of the material used. Products like pipes or channels are rarely weighed on scales. When buying, deal with theoretical weight, which is calculated according to the formula developed for each type of rental.

Find out how much rolled metal weighs a standard form, for example, a flat sheet, can be done by simple calculations. To do this, the dimensions of the sheet or square are multiplied by the thickness to find the volume, and then multiplied by the specific gravity of the iron alloy used. You can use the given in tables weighing 1 running meter. The data can be found on the internet. There are online calculators that allow you to determine the theoretical weight of any product.