Fallen logs are sawn into pieces to produce material that is conveniently shaped for construction and other work. They use coniferous and deciduous tree species, use all kinds of woodworking methods, as a result, various types of lumber are obtained. The products are intended for different purposes: construction, decoration, furniture manufacturing, etc.

Lumber classification

Plast they call the wide plane of the sawn material, also - any of the sides of a square bar or other product of a similar section. From the side of the core, the layer is called internal, and from the side of the sapwood - external. The narrow longitudinal sides at the sides are called edges, and ribs are located at their intersection with the faces. Cross-sections at the ends of the product are named butts... The distance of the lumber between the layers parallel to each other is the thickness, between the side edges - the width, between the end ends - the length of the product.

Depending on the strength materials are divided into types:

- Structural. Category with high values of compressive strength, bending, torsion for the construction of load-bearing elements of a building.

- Finishing. For wall cladding, partitions, production of unloaded structures.

Sort lumber by machine and manual method. In the first case, the indicators of elasticity, stretching are taken into account, in the second, visual rejection is carried out, attention is paid to defects, sizes.

End machining becomes the reason for a different classification:

- trimmed - cut parts to the required length;

- untrimmed - lumber along the length of the tree trunk.

Russia has GOST 84.86 - 1986, which determines the grade of wood materials. They make a distinction between materials in texture, texture. The concept of texture includes the characteristic of roughness, relief, smoothness of the surface, tactile and visual methods of determination are used.

- thin;

- rough;

- moderately thin.

Texture - the pattern of fibers on the plane of the material, which is perceived visually. This visual characteristic depends on the structure of various types of wood, the width of the trunk, and the number of annual rings. Take into account hairiness - raising the fibrous ends when sawing logs.

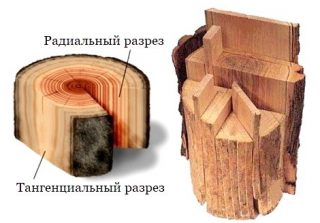

By sawing method

Radial sawing assumes a predominant location of the cuts in a direction close to the radii of the annual layers of the trunk.

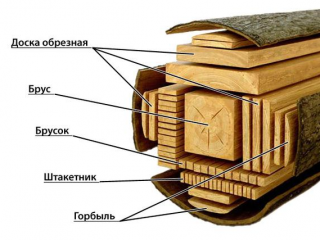

By assortment lumber includes the following types:

- Bar. The material has a thickness and width of at least 100 mm. Elements are prepared from solid logs or glued from separate boards. Distinguish two-piece (carriage), three-cante (timber with three machined planes) and four-cant a type.

- Bar. In this variety, the thickness is not more than 100 mm, and the width is not more than twice the thickness.Distinguish between solid and spliced bars, the second option involves connecting the boards into a single whole. Distinguish between planed and calibrated products.

- Board. Depending on the place of cutting in the log, core, central and side boards are distinguished. According to the type of processing, planed, one-sided planed and double-sided planed varieties are distinguished. The sizes of the boards are different depending on the needs.

- Sleeper. Release soaked elements for main railway lines, and untreated - for secondary tracks and station entrances. Products are edged (processed from all sides), semi-edged (on three sides), unedged (hewn from the top and bottom sides).

Obapol and croaker are similar in structure and shape. They are cut from the lateral surface of the trunk when making a square bar. The slab has only the inner face, and the outer one does not. In case of obapol, the outer side may also not be sawed off, or it may only be cut in half or for the entire length of the element.

By processing method

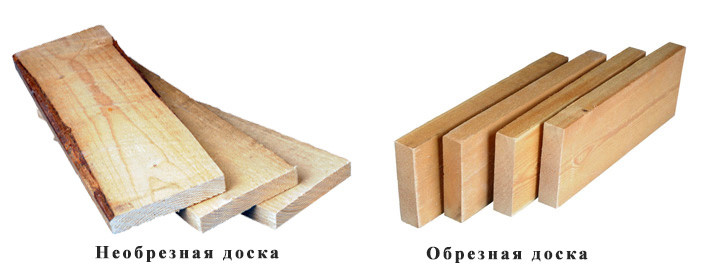

Edged board is a product with edges that are cut perpendicular to the face. On the surface, there may be wane in the amount allowed by regulatory documents. Runway edges can be parallel or non-parallel.

Edged lumber is made from logs by the method of longitudinal sawing, while cutting off the edges on which there is bark. The absence of such a coating protects against the development of rot, fungus, and insect settlements.

Unedged boards - material with partially sawn-off or completely not removed edges. The sweat is a volume that exceeds the permissible amount according to regulatory documents. Unedged lumber is also obtained by longitudinal sawing of logs. Conifers are used, deciduous ones are less common. They are used for ancillary work and where a beautiful view is not required.

Planed lumber - at least a single face or two side edges are planted. A smooth surface is obtained by processing on machines. Smooth products are used for front processing, which do not need additional decorative finishing.

Variety calibrated lumber is products that are dried to the standard moisture content and processed to the required dimensions. The category includes lining, Euro planks, special-purpose boards that have a certain section according to the standard.

Wood species

Conifers breeds are almost all evergreen, they are subdivided into light conifers (spruce, fir, cedar, etc.) and dark coniferous (larch, pine). Deciduous are represented by trees and shrubs, these include birch, aspen, alder, hornbeam, beech, ash, etc.

In the forestry and manufacturing industries, there are breed categories:

- The main. A woody variety that meets the requirements for environmental and management purposes.

- Secondary. Has less national economic significance.

- Unwanted. The breed does not meet the objectives of the industry in the current economic circumstances.

- Prevailing. Most common in a particular region or country as a whole.

Coniferous trunks show different strength indicators:

- Siberian cedar - 40 N / mm²;

- spruce - 80 N / mm²;

- pine - 100 N / mm²;

- larch - 105 N / mm².

Larch the most dense, therefore it is especially appreciated and expensive. It is used to make lining, high quality decking. Density pine trees below, but such material is easy to process. Spruce has less strength, but its plasticity allows it to be produced from running materials, for example, a rail. Cedar used where there are no heavy loads, wood is used for the manufacture of finishing materials.

Hardwood subdivided into types:

- solid;

- soft.

Oak durable, flexible, resists decay, durable veneer, plywood for joinery and furniture production is made of it. Ash has a beautiful texture, due to increased flexibility, it does not crack when dried. Elm characterized by heavy and elastic wood. Beech beautiful on the cut (white with a reddish tint), which is great for decorative purposes.

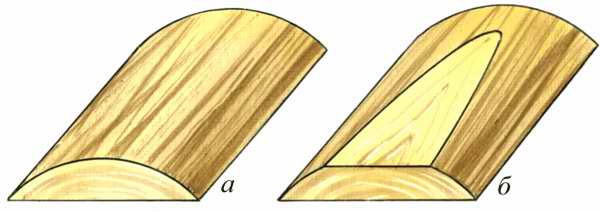

Plates and Quarters

Such blanks are obtained longitudinal sawing of logs, while the saw blade is carried out parallel to the wood fibers. Cutting is done by the method tossed (through), a bar is used, the cut is oriented tangentially or radially to the annual rings.

Varieties of elements:

- ridge the whole tree trunk from which the bark was removed is called; the diameter of such an array must be at least 25 cm;

- plate is a half of a ridge, divided along the direction of the fibers;

- quarter - half of the blank of the plate, if it is cut in half along the direction of the wood fibers.

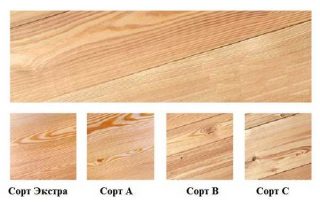

Grades of materials

Various materials have varieties:

- coniferous wood products (bars and boards) are divided into 5 varieties, while class 1-4 are classified as selected;

- bars are subdivided into 4 grades;

- products from deciduous trees are produced in three varieties.

When attributing to a certain class, they take into account the compliance with the dimensions, the parallelism of the edges and wide sides, the presence of defects, moisture, roughness and many other indicators.

Define classes with multiple methods:

- visually finding vices;

- forecasting probable strength according to several measurable indicators;

- a combination the first two ways.

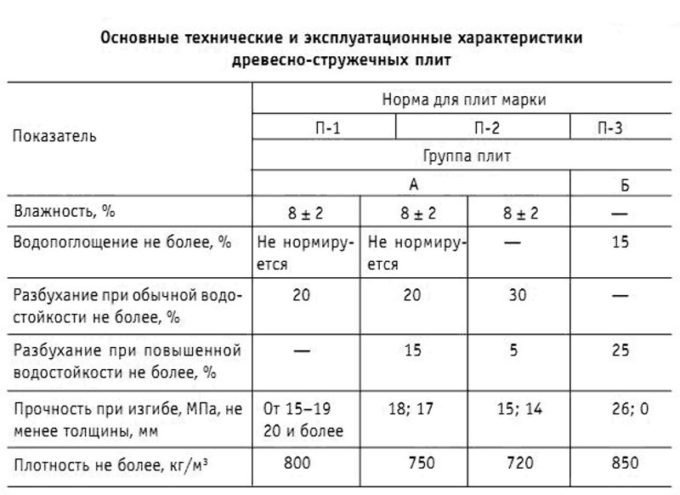

Chipboards

By density distinguish between products:

- low - up to 550 kg / m³;

- medium - 550 - 750 kg / m³;

- high - over 750 kg / m³.

For various conditions of use (humidity, chemical action), they are produced 7 types of chipboard with markings from P1 to P7... Produce slabs with sanded and unpolished surface that is fine-textured or smooth. Distinguish between products solid, hollow, layered and single-layer, there are options with an additional reinforcement organic and cellulose fibers.

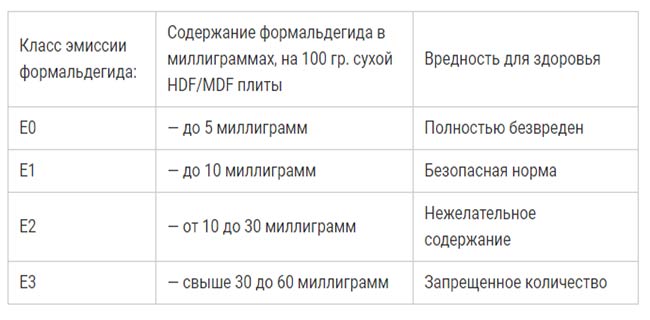

Formaldehyde content in mg per 100 g of dry panel are distinguished emission classes:

- E0 - no more than 5 mg (non-hazardous);

- E1 - 5 - 8 mg (can be installed in housing with a restriction);

- E2 - 8 - 30 mg (outdoors only).

Concentration limit harmful substances in the air of the room 0.5 mg / m. A person perceives an unpleasant odor even at a concentration of 0.4 mg / m3. The manufacturer indicates the emission class in the labeling on the product and in the certificate of conformity.

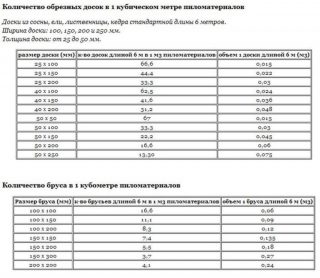

Sizes of lumber

Dimension standardization is needed to be able to calculate the required amount of material for a specific job.

Lumber is produced in sizes:

- lining, floor and edged board - width 65 - 275 mm, length 1000 - 6000 mm (gradation 250 mm), thickness 16 - 75 mm;

- bars and beams - width 40 - 275 mm, length 1000 - 6000 mm, thickness 40 - 275 mm;

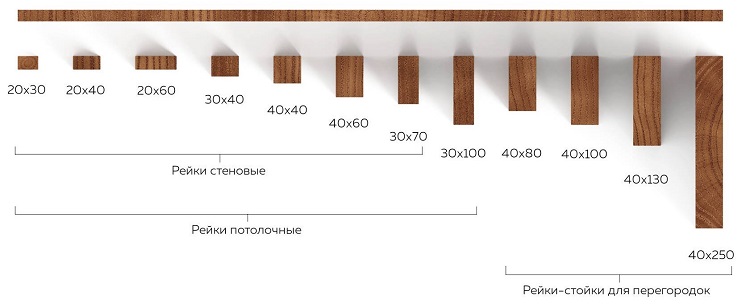

- rail - 25 x 50 mm, 25 x 40 mm, 20 x 40 mm, 22 x 50 mm;

- fence - length 500 - 1800 mm, width 40 - 100 mm, thickness 16 - 40 mm;

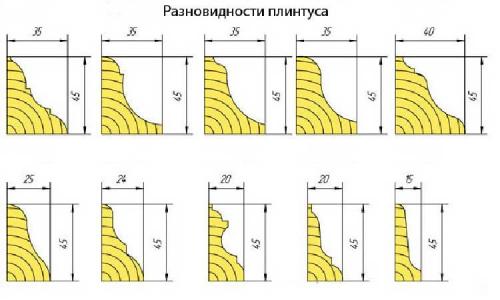

- plinth - length 1000 - 2000 mm, width 15 - 60 mm, height 40 - 80 mm;

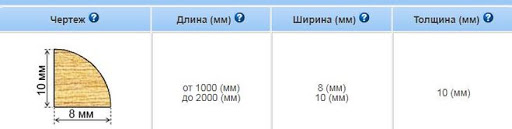

- glazing bead - length 1000 - 2000 mm, width 8 - 10 mm, thickness 10 mm.

Dimensions take off with a moisture content of 20%... Allowed tolerances of 5 mm in length, 1 - 3 mm in thickness.

Applications

Each industry has its own sawn timber and products.

The tree is used:

- in shipbuilding and mechanical engineering as a skin and frame for boats, ships, boats, lake and sports transport, decking, for bodies, other machine parts;

- in agricultural business they make machine parts from wood, build outbuildings, warehouses, hangars;

- in the construction industry lumber is needed for repair and maintenance work and for the construction of capital structures, surface finishing, manufacturing of window and door fillings, and ancillary work.

Lumber of a certain quality is used in the furniture industry and in the production of packaging.