Wavy metal profiles are produced in different sizes depending on the area of application and load. The dimensions of the profiled sheet are needed to calculate the required volume of material, determine the step of the crate. Metal strips are made only with a galvanized, aluzinc coating, a polymer layer is added to increase corrosion protection.

- Description of corrugated board and compliance with the regulatory framework

- Advantages and disadvantages of a professional sheet

- Production technology

- Application area

- Types of profiled sheets

- By form

- Other varieties

- Decoding of sheet marking

- Total and usable material width

- Length of corrugated sheets

- Material thickness

- Metal profile weight

- Tolerances and deviations of the dimensions of the corrugated board

Description of corrugated board and compliance with the regulatory framework

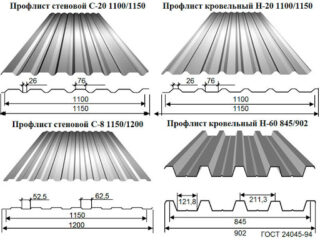

Corrugated material is a rolled product with periodic trapezoidal stiffeners with a height of 15 - 160 mm for roofing decks, and 8 - 44 mm for fences. On request, types of corrugated board are made for walls with a height of more than 44 mm. The corrugations are placed on the surface with the same pitch.

The performance characteristics of rolled metal are influenced by the following parameters:

- base metal and thickness;

- galvanized thickness;

- type of applied coating;

- the thickness of the polymer layer on the surface;

- waveform and stiffeners.

In the manufacture, they use GOST 19.904 - 1990, where the regulatory framework for cold-rolled sheet base is collected, GOST 30.246 - 1994 with specifications for the production of steel sheets with a decorative coating for building materials. GOST R 52.146 - 2003 contains standards for the production of hot-dip galvanized sheets with a polymer layer on continuous conveyors.

Advantages and disadvantages of a professional sheet

The profiled sheet is a finished product that does not require processing before being installed in the installation position. Installation is simple, and the length of the strips up to 12 meters allows you to avoid making joints on long slopes.

All types of coated profiled sheet have positive properties:

- Corrosion protection. The polymer layer on the surface protects against chemical attack and mechanical shock.

- Wide range of colors and patterns. Layers are made with a thickness of 25 - 20 microns, painted in different colors, drawings of stone, leather, wood, and others are made.

- Low weight. Thin sheets of iron are used in the base, and strength is obtained due to stiffening ribs and additional grooves.

The disadvantages of the profiled sheet include sound conductivity, this is especially important for the roof. The problem is eliminated by installing sound insulation, organizing air gaps in the roof structure.

Production technology

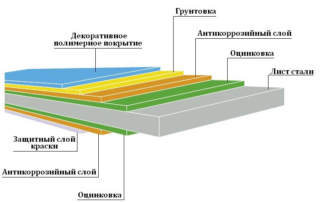

The material is produced from galvanized sheets by cold rolling on bending equipment. In the process, the metal is profiled, giving the waves a square or other shape to increase the rigidity and strength of the profile. The quality of the rolling equipment matters, since the thin film on the surface can be damaged during the production process.

Manufacturing steps:

- galvanizing steel sheets for corrosion protection;

- passivation of the applied layer to obtain an oxide film;

- priming the surface to increase adhesion;

- coloring with polymer compounds, varnishing;

- applying a protective composition.

Galvanized and painted profiled sheet is produced according to the same technology until the moment of painting. The polymer layer does not replace zinc plating, it only enhances the protective properties.On a thick film (150-200 microns), embossing is performed along the relief of the selected pattern, so that the profile can look realistic.

Application area

Galvanized types with different sheet sizes are placed as a fence and wall fencing. In industry, an inexpensive type of material is used for hangar roofs, large area sheds are assembled, and internal partitions are installed. Galvanized sheets last up to 20 - 25 years. Compared to the dyed ones, this is half the size (40 - 50 years).

Polymer-coated professional sheet is used as:

- facades cladding;

- roofing;

- fences for fences;

- self-supporting structures;

- fixed formwork;

- filling between elements of frame structures.

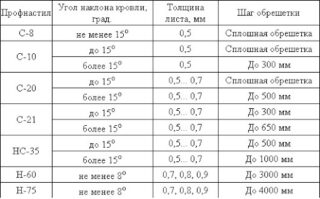

The material does not load the foundation, therefore, when cladding the walls of the house, reinforcement of the base is not required. The professional sheet is used for inclined slopes, and flat roofs are also made. Durability allows it to withstand the weight of accumulated snow and ice on the surface. Profiled sheeting saves material on the crate when constructing slopes with a large slope.

Types of profiled sheets

Each type of profile differs in geometric parameters, due to which the indicators of bearing capacity, stiffness, and reliability change.

Types of corrugated board are produced, depending on the original workpiece and production technology:

- metal profiled sheet without any coating;

- galvanized corrugated board with oxide film;

- galvanized profile with decorative protective layer;

- metal profile with a base of aluminum, chromium-nickel iron, copper;

- special-purpose products with perforation, embossing, bent and others.

The distance between the protrusions matters. The working width of the profiled sheet for the fence, roof, facade cladding depends on this, since the material is placed with overlapping waves.

Profiled sheets are distinguished depending on the characteristics:

- area of use;

- the height of the stiffeners;

- corrugation shape;

- the dimensions of the corrugated board.

Width, length, thickness are also standard indicators, taking into account the useful and total area of the strip.

By form

More often, a profile with a trapezoidal section is produced, but the corrugation is also made of a different shape. European standards allow lugs with rounded ridges, reinforced wall and ridge, with a groove on the top of the wave.

Available in waveform varieties:

- Triangular. Used for lightly loaded roofs, wall cladding.

- Wide corrugation. A common option is used for roofs, fences.

- Composite. A complex pattern requires the installation of lathing elements under each undulating ledge along the length of the profiled sheet.

- Deck. More often put on the cladding of walls, fences, cover sheds, pavilions.

Products with a constant cross-section are produced along the entire length of the profile or relief stamping is performed on the shelves and walls. Alternatively, you can consider traditional metal tiles with a complex structure of waves, which are repeated along the length of the sheet.

Other varieties

The galvanized profiled sheet is additionally protected with a polymer coating. Films on the surface have different thicknesses and properties

Varieties are used:

- Acrylic. They are referred to as short-lived layers that fade after 3 to 4 years and begin to peel off. The thickness of such a coating is 25 microns, and sheets are used for temporary buildings, utility hangars, sheds.

- Polyester. The second type of budget material with improved properties. The thickness is also 25 microns, but the UV resistance is increased. The film is easily damaged by careless use.

- Plastisol. Contains PVC particles, plasticizers. The thickness of 200m km will allow you to make relief embossing, the coating loses its color intensity over time.

- Pural. The composition contains polyurethane, polyamide, acrylic. The 50 µm layer works well without degradation, even in an aggressive environment.

The most durable coating is considered to be PVDF (polydifluorionate).Placed in a chemical industry, in structures on the shores of salt lakes and seas.

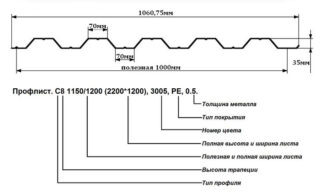

Decoding of sheet marking

The first letter of the marking means:

- H - bearing type of profiled sheet used for roofs with insulation, taking into account the load from wind, snow;

- NP - used for loaded floorings of reinforced concrete floors, fixed formwork;

- NK - for roofing with enclosing and bearing function;

- C - wall decoration, filling device in frame buildings, decoration of fences;

- NS - a universal profile for roofs and facades.

The number after the first letter indicates the height of the ribs in millimeters. The second after it is the thickness of the profiled sheet. The third indicates the installation width of the strip, and the last indicates the length of the item in the package.

Total and usable material width

Usually, sheets are produced with a width of 0.98 - 1.85 meters. Distinguish between useful and total stripe size. The working width, which is used when calculating the number of elements, will always be less than the total. The parameter is important, along with the wave height.

According to the technology, the sheets are placed with an overlap by one wave, while the adjacent protrusions overlap in the course of the row. As a result, the width is partially absorbed, and the actual consumption of the strips increases. For this case, the concept of useful width is used, which is introduced as an additional characteristic. The parameter corresponds to the clearance that the corrugated sheet can overlap after overlapping.

Manufacturers are obliged to indicate the useful width in millimeters so that the buyer can immediately see from the marking what size one strip will cover.

Rules for using parameters:

- useful width helps the user to count the number of lanes;

- the total is indicated in the registration of the check when calculating the purchase price;

- the useful area is calculated by multiplying the corresponding width by the length of the sheet.

To independently calculate the useful width of the sheet, you need to subtract the transverse size of the wave from the total, which will be covered by the protrusion of the adjacent strip. The difference between the two indicators directly depends on the width and height of the wave itself. The more convex the corrugation, the greater the difference between the working area and the total area.

For the construction of fences in the height of one sheet of corrugated board with transverse stripes, a total width is used. The parameter will show the true fill height, since the elements will not connect with the overlapping wave.

Length of corrugated sheets

The convenience of the material is that the developer orders the length of the metal profile according to the length of the roof slopes. This makes it possible to abandon the transverse joints, which increases the tightness of the coating. The length can be ordered in the range from 1.0 to 12.0 meters.

Installation features:

- order a profiled sheet in length in multiples of 0.5 or 1.0 m (depending on the manufacturer);

- if they acquire a composite length, the overlap is taken into account;

- it is better to order composite strips at the factory, since when cutting at the facility, the sewn layer at the place of the tool passage is broken;

- the amount of overlap depends on the slope of the roof - decreases with increasing angle.

In private construction, the size of the slopes rarely exceeds 6 m, so the elements are lightweight. They can be installed on their own, if there is no strong wind outside (windage matters during installation).

Material thickness

Profiled metal is produced with a thickness of 0.4 - 1.0 mm, the most purchased are sheets in the range of 0.45 - 0.55 mm. Such parameters allow builders to move along the roof material without deformation.

Use the thickness for different types of corrugated board:

- marking H - made with a thickness of 0.55 - 1.0 mm;

- NS designation - 0.55 - 0.85 mm;

- view C is the thinnest - 0.4 - 0.7 mm.

The value is taken by the thickness of the metal base. Protective zinc plating, polymer films are measured in microns, and not in millimeters, so they do not significantly affect the overall thickness.

In accordance with GOST 24.045 - 2010, a deviation from the indicators indicated in the passport by 0.06 mm in one direction or another is allowed. For example, with a thickness of 0.45 mm indicated in the documents, an indicator of 0.39 - 0.51 mm is allowed.

Metal profile weight

You need to know the length, width of the sheet to find the area, and the weight per square meter to calculate the total mass of one strip. The weight of the profiled sheet depends on the thickness, the gap between the waves, the height of the corrugation, the type of polymer coating.

Weight of individual species:

- Wall S. The basis is high-quality steel, and the weight per square meter ranges from 4.25 to 6.78 kg.

- Bearing N. Weight directly depends on the thickness of the workpiece material, the estimated mass of the square of the profile varies in the range of 8.67 - 17.17 kg.

- Universal NS. A square of a multivariate variety weighs from 4.5 to 15.1 kg, depending on the height of the corrugation.

The weight of the profiled sheet is needed for technical calculations that determine the total weight of the roof. The data is used to calculate load-bearing structures (walls, beams, foundations).

Tolerances and deviations of the dimensions of the corrugated board

Deviations occur during production and often depend on the quality of the rolling conveyor.

Maximum permissible parameter changes:

- for a profile with a height of 8 - 18 mm, it is allowed in height ± 1.0 mm, in width - ± 8.0 mm, in length - ± 2.0 - 6.0 mm;

- 20 - 59 mm - in height ± 1.5 mm, in width and length similar to the previous type;

- 60 - 74 mm - in height ± 2.0 mm is allowed, width and length - the same;

- 75 - 160 mm - height tolerance 2.5 mm, width ± 15.0 mm, length - ± 2.0 - 6.0 mm.

If the discrepancy in length exceeds the norm, by agreement with the user, this may not be considered a gross violation.

The crescent shape is not allowed more than 5.0 mm for every 3 meters of length with a length of up to 6 m, and after 6 m, only 1.5 mm is allowed for each running meter. Waviness should not exceed 1.5 mm on flat surfaces and 3.0 mm on extreme shelves.