Wave asbestos slate is used for roofing, flat to create light walls in summer showers, kitchens and storage rooms. After dismantling, the material remains in demand. Fences for beds and vegetable gardens are made of it, they are dug in along the fences as counter-digging. The question of the dangers of slate for human health and the environment for many property owners remains in the background. To assess the real danger of asbestos-cement slabs, you need to understand the technology of their production and operation features.

Slate creation technique

The slate includes cement, water and asbestos fiber. To give the finished product strength, raw materials are added cellulose and fiberglass fillersand the panels are treated with hydrophobic impregnation.

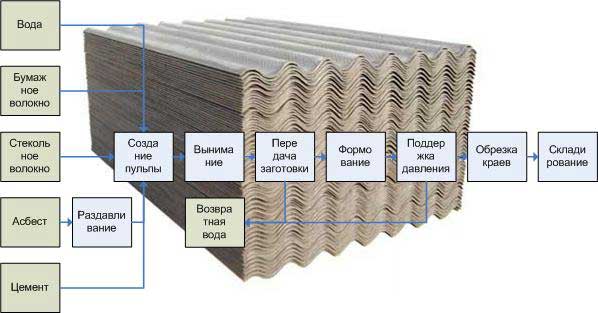

The production cycle consists of the following stages:

- Pulp preparation. The ingredients are mixed in a mixer until smooth.

- Dosing of the substance, her partial dehydration.

- Loading raw materials into molds, the formation of a workpiece of a given shape. Pumping out excess water.

- Pressing and drying... Produced by a powerful press.

- Cropping to the appropriate GOST or TU sizes.

- Processing of products by impregnation. Some models are additionally painted. This significantly increases the resistance of the material to moisture and ultraviolet light.

The pumped-out liquid and cuttings are sent for recycling and again put into production. This approach reduces the cost of goods and the burden on the environment.