Fences made of profiled sheet are distinguished by sufficient strength, presentability, durability and the ability to do it yourself. The protective qualities of the structure allow you to reliably protect the site from intruders. An integral part of the structure is a lock on the gate made of corrugated board. Depending on his choice and the correct installation, this part of the fence can be both the weakest and the strongest link. To achieve a high-quality result, you need to understand the classification of locking devices, their pros, cons and installation features.

Description of species

Choosing a door lock made of corrugated board, you should initially decide on the type of its installation.

The following types of products are on sale:

- Hinged. They consist of a body, into which a removable or folding bow is inserted. The closure is done by inserting the bow into the hinges welded to the frame. The design is simple, reliable, but extremely vulnerable, since all its parts are freely available.

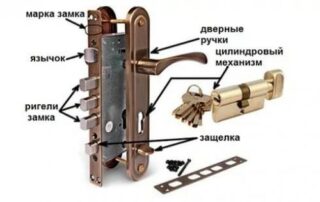

- Mortise. The body is inserted directly into the goal post. From the outside they are unlocked with a key, from the inside there can be both a well and a latch. Products are distinguished by increased reliability, provided that the frame is strengthened and the gap between the sash is closed with a metal strip.

- Overhead. The easiest option in terms of installation. The device is simply bolted to a metal pipe, and a turnkey hole is made in the canvas. Opposite the body, a counter bar is attached to the support for receiving the crossbar.

The design takes into account such parameters as the ratio of the width of the wicket itself, the size of the front plate of the lock, as well as the depth of its body.

Next, you need to choose the most suitable type of locking mechanism.

Manufacturers offer the following designs:

- Electromechanical. Reliable devices in all respects. They are distinguished by their strength and versatility. The combination of numbers can be changed as needed at least several times a day. The weak point is dependence on electricity, but there is duplication with a simple key. Connecting to an uninterruptible power supply solves this problem.

- Code. Quite common, but not the most popular devices. Their opening is carried out by simultaneously pressing several buttons, and closing by simple slamming. The disadvantage is that the operating buttons are quickly overwritten and attackers can easily determine the desired combination.

- Electromagnetic. Such devices (intercoms) are installed on the doors of multi-storey buildings. The leaves are held closed by two electric magnets. When an electronic key is applied to the remote control, the signal is interrupted and the doors can be opened. On the one hand, it is convenient, but not reliable, both in terms of the dependence on the current and the ease of selecting the signal frequency.

To ensure more complete safety of their valuables, many property owners put several different types of constipation, where the principle of duplication is applied.

Criterias of choice

When choosing a street lock for a wicket made of corrugated board, it is necessary to take into account that it must be very reliable, so that instead of a means of protection from outsiders, it does not become an obstacle to the penetration of property owners into their territory.

The device must meet the following criteria:

- sufficient strength to withstand burglary and perceptible mechanical stress;

- long service life, at least a ten-year resource of opening-closing cycles;

- ease of use, the application of little effort to perform certain actions;

- resistance to moisture, no parts prone to corrosion;

- maintaining performance at extremely high and low temperatures;

- the possibility of self-service, repair or replacement.

Locking profiled systems should not weaken the bearing indicators of gates and wickets.

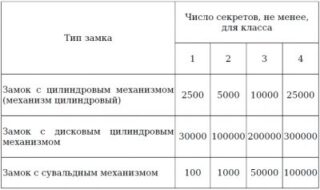

Another selection criterion is the security classes of the locks.

Cylinder systems are the easiest to open. Even the most complex larvae are easily opened by robbers experienced in such matters. The plus is that the cylinder is easy to replace in the event of a breakdown.

Lever devices are much more reliable. Their minus is rather large. The advantage lies in the collapsible housing. Gaining access to the internal mechanisms allows you to timely clean them from dirt and change the lubricant. If you have locksmith skills, you can change worn out levers.

It is almost impossible for outsiders to open smartlocks, but they need electricity to work. The opening is performed after scanning the personal data of the owners with a laser - the retina of the eyes, fingerprint, characteristic points of the face. It is almost impossible to open such devices, as well as to put them on your own.

The cost of products directly depends on their complexity, used in the manufacture of materials and technologies. The price of padlocks varies between 300-600 rubles, overhead locks 500-1200 rubles, electromechanical locks reach 3000 rubles, and the most effective smartlocks can cost up to 12,000 rubles without installation and configuration services. However, it is not recommended to save on the protection of real estate, which is estimated at millions.

DIY installation

Step-by-step instructions for equipping a wicket or gate with locks comes down to three main steps:

- Design, implementation of markup.

- Making holes for the tongue and fasteners.

- Product installation, installation of strips, handles, latches.

To work, you will need a drill, grinder, tape measure, screwdrivers and wrenches. Gloves and goggles should be used.

The sequence of mounting the padlock:

- Basting eyelets for supports. It is better to take titanium corner hinges, as they are very durable and will not rust. It is necessary to check that the parts do not interfere with the shutters freely closing and diverging.

- Spot tack welding. Correcting their position. Making the final seam.

- Cleaning metal from scale, processing with a primer and high-quality paint to match the color of the supports.

- Attaches a bolt to the inside of the frame to close from the inside. It should be no less powerful and sturdy than the outdoor device.

- Removing the inner leaf of the sash. Studying the rack. If necessary, it is reinforced with an additional strip or a box is welded on top.

- Transfer of the contour of the case to the racks in accordance with the attached instructions.

- Drilling holes for bolts, wrench in column and outer blade. Making an opening for the body. It is better to first make the holes, and then connect them with a grinder.

- Treatment of the edges of the hole, openings with anti-corrosion agent.

- Lock inset. It is first inserted into the opening, then bolted into place. Surplus is cut off.

- Making a counter opening on an adjacent rack. It is easier to outline it with the help of toothpaste applied to the tongue of the constipation.

- Assembling the device, returning the canvas to its place, attaching strips and handles.

- Fitting the product to the frame, drawing points for drilling.

- Hole making, anti-corrosion metal treatment.

- Screwing the body to the frame, attaching fittings.

Finally, a striker is welded to the support. If the metal is thin, it is better to bolt it.

What is forbidden to do when installing the lock

Errors when installing the lock on corrugated structures are fraught with jamming and even breakdowns.

It is not allowed to perform the following actions:

- Embed the lock into wooden posts or thin pipes. They can break under stress.

- Weld the lugs to the supports. Such a connection is extremely unreliable, the hinges can be easily knocked down with any hard and heavy object.

- Screw the lock to the profiled sheet. This design will fail almost immediately.

- Violation of geometry. The crossbar should walk smoothly and freely, not clinging to any obstacles. If there is a bias, then this negatively affects the internal mechanism.

- Leave the bolt heads on the outside of the guardrail. There they can be easily unscrewed or cut off, after which access to the house does not present any particular difficulties.

The most important thing is not to weld the lock to the pipe. From strong heating, its body and internal parts are irreparably deformed.

Initially, the bolt must be closed with a visor to protect it from snow and rain. This will not help with condensation. A universal solution is to completely fill the body and the inside of the larva with liquid silicone. At least once a year, the product must be disassembled, dirt removed and fresh paint applied. Distortions must be corrected immediately using appropriate repair methods.