Recovering heat in a house or industrial building saves the energy spent on using the ventilation system. This mechanism is especially useful in conditions of limited thermal resource or the impossibility of providing sufficiently efficient heating of the room.

Description and operating principle of the heat recuperator

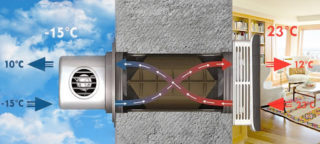

The literal meaning of the term "recuperation" is "return back". Heat recovery in ventilation systems implies the transfer of part of it from the exhaust air masses removed from the room to the cold air coming from the street. As a result, the latter is able to heat up by 2/3 of the difference between the internal and external temperatures. The use of an air recuperator allows to reduce the cost of heating and ventilation of the room.

Industrial devices of this type operate on electricity. However, they can be left on around the clock.

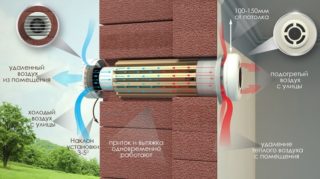

The principle of operation of the recuperator is implemented as follows: air masses from the street are sent to the serviced building through the ventilation duct. In the ventilation unit, they are cleaned from dust, heated up and go into the room. Stale air from toilets, utility rooms, from the kitchen passes into the apparatus and gives off heat to the masses coming from outside. Waste air is discharged into the external environment after it has cooled.

The devices are equipped with control panels, through which you can perform the following actions:

- regulate the temperature of the air masses entering the room;

- adjust the frequency of filter change;

- control the fan speed.

You can set a mode in which the air exchange is not so intensive on certain days or times of the day. This move helps to save energy.

Varieties of recuperators for ventilation

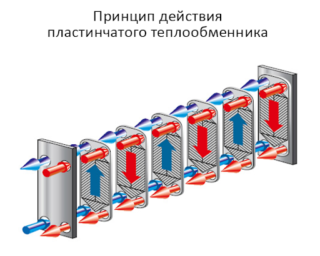

Lamellar

The models are very popular due to their affordable price and high efficiency. Simple installation also contributes to this. Often they are purchased for cottage buildings, commercial premises. Air recuperation in them is carried out while passing through a structure of a large number of plates. The structure of such devices predisposes to the accumulation of condensed moisture, therefore, they are often equipped with shutter devices that prevent the fan from sucking in and directing water into the ventilation duct. In winter, there is a risk of ice floes.

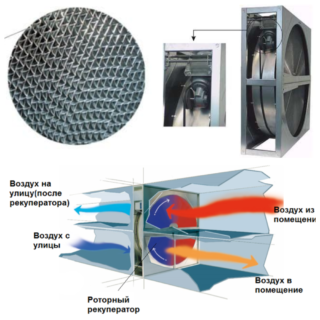

Rotary

The heat recuperator is equipped with a rotating rotor. It transfers heat between the supply and exhaust paths. The driving speed determines the recuperation values. The devices have a high efficiency (up to 90%) and a corresponding cost. They are used in large premises for industrial and other purposes. The openness of the design increases the likelihood of odors transferring from the exhaust air to the incoming air.

With intermediate heating medium

Usually, plain water acts as a heat transfer fluid circulating between a pair of heat exchange elements. Ethylene glycol solution is sometimes used. One exchanger is mounted in the supply ventilation duct, the second in the outflow duct.The liquid is heated by the exhaust air and gives off heat to the supply air. Due to the closed structure, dirt and odors from the exhaust duct do not enter the supply duct. Such a recuperator has a low efficiency (50-60%), therefore, it is installed in those places where it is important to exclude mixing of streams. This usually implies high pollution of the exhaust air or its saturation with harmful compounds.

Chamber

The design is based on a chamber divided into 2 zones by a partition. The exhaust air heats up one of the parts. The partition changes the direction of the air flow so that the supply masses are heated from the warm inner surface of the chamber. The device is quite effective (up to 80%), but there is a possibility of odors and dirt getting into the jet entering the room.

Heat pipes

This design is based on tubes filled with freon. The spent masses, passing through the device, transfer their heat to the pipes, the gas evaporates. When the air coming from the street passes through the system, vapor condensation occurs with the transition of the substance into a liquid form. The efficiency of such a recuperative device is low (up to 70%).

Advantages and disadvantages

The main advantage of these devices is the ability to regulate the inflow and outflow of air masses and their ratio. Thanks to the heating of the exhaust gas flow coming from the street, the amount of energy spent by the heating devices to achieve the required air temperature in the room is reduced. This saves energy costs. This applies to using the device in an industrial setting, buying an inexpensive home model, or making it yourself. It is economically unprofitable to purchase an expensive recuperator for your home.

The mechanism allows you to reduce heat loss while maintaining the flow of fresh air into the room. A combination of a constant supply of oxygen and maintaining an optimal temperature is provided. When it is warm enough outside, the user may not connect the heaters, which additionally helps to save energy. This ensures effective removal of unpleasant odors and impurities in the air. The advantages include the small size of the units and the ease of installation. They are available in a large number of options - for placement in a bathroom, integration into a niche, etc.

The disadvantages include high prices for devices (from 20 to 100 thousand rubles or more), which encourages craftsmen to create plate-type devices with their own hands. In addition, models with an open design may not be effective enough to remove odors and contaminants from waste air masses.

If the device has become unusable, the complexity of the repair depends on which unit was damaged. Troubleshooting mechanical faults is generally easier and more affordable than troubleshooting complex electronics.

Selecting an installation with a recuperator

The system is designed based on the purpose of the serviced premises, its area and internal structure, as well as the estimated number of people who will live or work there. The duct grid is installed taking into account the pressure losses in the ventilation system.

One of the important factors is the efficiency of the recuperator. It depends on the internal structure of the device, on the material and type of heat exchanger:

- The rotor variants equipped with automatic control by means of sensors are distinguished by high efficiency. However, in winter, such devices can become icy.

- When using a paper exchanger, the efficiency is average (60-70%), but such models are resistant to freezing.

- For aluminum versions, the design of which is prone to icing, additional electricity has to be spent to prevent it.

In any case, the efficiency of devices at very low temperatures (less than -10 ° C) tends to decrease. It is also affected by high humidity.

It is necessary to pay attention to the thickness of the walls of the device and the raw materials from which the cold bridges are made. The thinner the walls, the more they are susceptible to winter frosting. On sale there are often models with a parameter of 3 cm, which is insufficient for winter conditions. When purchasing such a device, it must be equipped with an additional insulating layer when the temperature outside the window drops below zero. The same applies to models with an aluminum body.

Another important parameter is the free head of ventilation devices. In this case, the figure of the indicator is not considered by itself, but in relation to the parameters of the system (in particular, the pressure) in which the device is to be operated. The power of the device and its ability to provide the required volume of hourly air flow are also important. A plus is also high-quality automation with a versatile set of options, which provides the ability to adjust parameters based on sensor readings. In this case, the user does not need to constantly monitor the temperature indicators and quickly adjust the system in accordance with them.

Popular manufacturers

Among the inexpensive compact units is the Nova-300 Sensitive model from the Danish company. Shuft... The company's products, presented on the Russian market, are adapted to the climatic conditions of the country and can operate without preheating at temperatures above -10 ° C. The device has a highly efficient recuperator (declared efficiency - 94%) and high-quality filters that trap dust particles and unpleasant odors. The performance of the model is not very high (up to 200 cubic meters per hour), but it is quite suitable for servicing a home or office space. The heating element is made of ceramic. The fan can operate in 3 modes. The unit has a WiFi module, thanks to which the user can configure it using a smartphone. It is possible to regulate the temperature parameters and link the operation of the device to certain time intervals.

Inexpensive models for apartments and offices are produced by the company Electrolux... One such device is the EPVS-200. It works almost silently. The efficiency of the recuperative device is 85%, there is a frost protection unit and 2 fan operation modes. The system allows you to maintain air humidity at a given level. Implemented remote control option and self-diagnostics of problems. The disadvantage is the lack of an air cooler.

Italian firm Royal clima produces models of the middle price category with high performance (330 cubic meters per hour). The RCS 350 system is designed for suspended installation. Works silently, equipped with a plate heat exchanger with an efficiency of 90%. Functioning parameters can be set remotely by means of the remote control. The recuperator works efficiently at temperatures down to -20 ° C.

The models of a German company differ in a democratic price (less than 15 thousand rubles). Winzel and Ukrainian Vents... Unlike previous devices, these products are of the decentralized type. Both of them are capable of operating at low temperatures without freezing, have a high recuperator efficiency (88 and 90%, respectively), but have a low ventilation capacity (50 cubic meters per hour). Suitable for installation in an apartment or a small private house.

Decentralized plants with plate exchangers are also produced by Royal Clima. They are equipped with additional functions (air ionization, additional carbon filter), but they have a high price. The hourly productivity reaches 150 cubic meters. The control is carried out through the remote control.

The use of heat recuperators allows you to save resources on heating the premises while maintaining the supply of fresh air. The installation must be selected based on the design parameters of the system.