For the device of ventilation systems, a flexible air duct is often used. The element has the form of a corrugated sleeve that can be bent at different angles. The air duct has an internal rigid frame made of special steel wire of increased rigidity. The element can have multilayer walls for the purpose of heat, noise, sound insulation.

What and how flexible air ducts are made of

The corrugated hose for ventilation is made of aluminum foil, polyvinyl chloride (PVC), polyester compounds, polyolefin film, stainless steel or solid foil sheets.

The manufacturing process for ventilation elements looks like this:

- Spirally bent rigid wire is pasted over on both sides with aluminum or foil strips.

- The outer material is glued together in a spiral. As an adhesive, acrylic glue with special fire-fighting non-combustible impurities is used.

- Depending on the type of corrugated sleeve produced, the layers of the outer tape can be from 2 to 6.

Frameless flexible air ducts were launched into wide production. They are made from soft PVC or solid aluminum sheets. Such elements bend easily at any angle, are convenient to work with, and are light in weight. The cost of frameless sleeves is an order of magnitude lower.

Specifications

Flexible corrugation for ventilation is selected according to technical characteristics.

- Manufacturing material (aluminum, PVC, polyester).

- The working temperature of the refractory and heat-resistant sleeves is from -30 to +140 degrees.

- Inner diameter - from 100 mm and more.

- The length in the compressed and stretched state is from 1.5 m and more.

- The wire thickness of the frame is from 0.8 to 1.7 mm.

- The coefficient of friction resistance is 0.02–0.05. The lower it is, the lower the noise level when transporting air masses.

- Air flow speed - from 20 m / sec.

With the help of a corrugated ventilation sleeve, you can arrange the system in confined spaces or place it under a suspended, stretch ceiling.

Types of flexible air ducts

The corrugated air duct is available in several types:

- No thermal insulation. Non-insulated sleeves are made of aluminum foil with the addition of polyester. More often, such elements are used for the installation of ventilation systems in hidden areas of the room or for joining the main line with ventilation grilles.

- Equipped with thermal insulation. Such sleeves are obligatory for those rooms in which there is no heating. Otherwise, condensation will form in the line, which sooner or later will disable the entire system. Insulation is placed between two layers of aluminum foil or PVC. It is difficult to install such elements on your own without damaging them.

- Heat and sound insulating. In this case, the corrugated sleeve is designed in such a way that it does not allow condensate to be present in the line and at the same time reduces the coefficient of frictional resistance of the air inside. Most often, insulated types of sleeves have several layers of material. The diameter of the elements varies from 10 cm to 35 cm and sometimes even higher. The pitch of the spiral is from 25 cm.

- Silencers. The sleeves are PVC coated on both sides.Due to this, they have minimal resistance to the flow of air masses, therefore, they have a low noise level in operation.

Flexible plastic ventilation ducts are not prone to build up static electricity. But this does not negate the need to ground the entire ventilation system.

Where products are used

The use of flexible ventilation ducts is noted in the following conditions:

- installation of air conditioning systems in residential and commercial premises;

- at chemical plants;

- in the food industry;

- in pharmaceutical factories;

- in the oil refining industry, etc.

Such elements allow transporting even smoke and other contaminated air masses without harm to their inner walls.

Installation rules and guidelines

To mount a flexible ventilation duct according to all the rules, you need to adhere to the following recommendations:

- In rooms with temperature extremes or in unheated buildings, only insulated air ducts must be installed. For these purposes, it is better to call a professional, since the sleeve has an impressive weight and requires careful handling.

- When installing a heat-insulating corrugated sleeve, the joints between the elements must be glued with a special tape. It helps to additionally retain heat and reduce the noise level when transporting air masses.

- Before starting work, the flexible air ducts must be stretched to their maximum length. This position reduces the air resistance when air moves in the pipes and reduces the noise level.

- To maintain the pressure in the line, it is necessary to make the maximum turning radius. It must be at least two pipe diameters.

- A combination of PVC corrugated pipes with steel or aluminum structures is allowed.

- The main line is located taking into account the direction of the spiral turn in the frame. To do this, you need to focus on the direction of the swirling flow of air masses transported by the hood. Often the direction of the spiral turn is indicated on the packaging with the corrugated element.

- For the vertical sections of the line, rigid steel elements are used.

- The maximum temperature load on flexible air ducts must be taken into account when choosing them.

- Under no circumstances should corrugated ventilation sleeves be installed in the ground.

- To seal all joints, special flexible inserts are used.

- Bending or sagging more than 5 mm is not allowed between adjacent fasteners.

- The flexible ventilation line must not come into contact with heating elements.

A competent approach to the organization of the ventilation system will save you from unforeseen costs associated with the repair or replacement of equipment.

Tools and materials

For a flexible ventilation device, it is necessary to prepare the following materials and tools:

- roulette;

- marker;

- nippers;

- pliers;

- knife;

- screwdriver;

- protective glasses and gloves;

- hose clamps;

- mounting tape.

For independent work, it is recommended to use the help of a friend or neighbor. It is easier for two to lift and fix flexible air ducts.

Stages of work

To perform an independent installation of a small section of the ventilation system, you must do the following:

- Measure the distance from the exhaust outlet to the final point of the ventilation system, which will be connected to each other by means of a sleeve.

- Choose a flexible plastic duct or aluminum sleeve of the desired size. The diameters of the outlet and flexible duct must match.

- Connect one end of the sleeve to the hood in the kitchen and fix it with a clamp.

- Stretch the corrugation as much as possible from the point of attachment to the hood towards the outlet.Make bends to the recommended radius so as not to disturb the pressure in the system.

- If the length of the line is long, secure the hose with clamps with rubber gaskets in increments of 1–1.5 m. The diameter of the clamp must match the section of the hose. Otherwise, the pinched sleeve will not work correctly.

The passage of a flexible metallized or PVC element through the wall is carried out only with the use of a rigid sleeve. The same applies to the insulated corrugation for ventilation. All joints must be sealed.

Sagging of the pipe is possible no more than 5 cm for each meter of the line length.

Restrictions on the use of flexible duct

No matter how convenient the flexible sleeve is in installation, it is not always possible to use it. The following conditions and situations are prohibited:

- vertical highways with a height difference of 6 m (above 2 floors);

- ventilation systems with a temperature of incoming air masses from +120 degrees;

- systems and lines with excess heat in their individual sections;

- outdoor ventilation lines (except when the reinforced corrugated hose is protected from atmospheric precipitation and solar radiation);

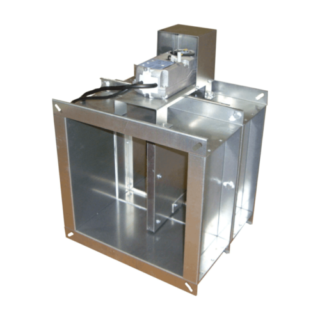

- laying the line through walls and floors, where it is necessary to use a smoke exhaust valve or automatic fire-prevention damper;

- laying a line through the walls of buildings that have a fire resistance rating of more than 1 hour;

- direct contact of a metal or PVC element with aggressive media or abrasives.

In addition, it is unacceptable to install flexible ventilation in industrial kitchens, ironing rooms, laundries, unless otherwise indicated by the manufacturer.

Popular manufacturers

The most popular on the market are air ducts from such manufacturers:

- ALUDUCT. The brand manufactures products that can be operated at temperatures in the system from -30 degrees to +140 degrees. Maximum working pressure up to 2,500 Pa. And the speed of air masses is 30 m / s.

- VENTPROFIL. Russian-made products. The average price is from 430 rubles for a 10-meter sleeve with a section of 102 mm for non-insulated material. The working temperature of the air ducts is from -30 to +100 degrees. Maximum working pressure up to 2500 PA.

- Dec. Russian manufacturer of products. The main feature of Dec air ducts is that they can be used in systems with a high content of aggressive substances.

- Diaflex. Russian-made products. The company offers hoses of the Economy, Classic and Premium series in all types of air ducts - non-insulated, insulated, sound and noise absorbing.

- AIRONE. Another major Russian manufacturer of elements for ventilation systems. The products are of high quality and optimal technical characteristics. The working temperature of the elements is from - 30 to +100 degrees.

When choosing a flexible hose for the ventilation system for your home, it is imperative to take measurements of the diameters of the inlet and outlet of the hood.