A prerequisite for maintaining a comfortable indoor climate is constant air renewal. Before choosing the type of ventilation system, it is important to consider the possibility of controlling the intensity of air flows. For these purposes, special devices are used - anemostats for ventilation. You should familiarize yourself with the principle of operation, characteristics and the list of popular models on sale.

Definition of the concept

Automatic air diffusers are installed at the end points of the duct and are designed to evenly distribute flows in a confined space. In fact, they are analogs of a classic diffuser or a typical grille installed in ventilation systems. These elements are also used in heating systems and various types of air conditioners. The main task of such a device is the distribution of air flows coming from outside or directed into the exhaust pipe.

The supply and exhaust air diffuser is responsible for a number of auxiliary functions:

- adjusting the volume of air taken in from the outside;

- blocking drafts;

- ventilation of premises;

- blocking the air ducts is like a damper.

Some models of these devices contain a filter element that retains dust impurities that are always present in the outdoor air.

What's the difference with a diffuser

The diffuser and the diffuser are intended for the same purpose, but the principles of their operation are markedly different. The difference between these devices is as follows:

- the diffuser is not able to change the intensity of air flows;

- the angles of inclination of its working lamellas are strictly fixed;

- to control the volume of the passed air masses, special devices will be required - manually controlled dampers.

The diffusers do not require any additional elements, since all functions are already included in them.

Differences in purpose

According to their functional purpose (the principle of air flow distribution), anemostats are divided into three types: supply, exhaust and combined. The former contain a special element in the form of a concave plate or shield. Due to this shape, the device has low aerodynamic resistance, which makes it possible to evenly distribute the incoming air flows circulating in the supply ventilation.

In exhaust models, a smooth outer diffuser cover ensures an unobstructed outflow of exhaust air. Combined devices contain two diffuser hoods, access to each of which is selected manually. For this, they have two slots located in the area of the divider plates.

In the supply mode, one of the gaps is open (near the concave plate), and the other is blocked. When the appliance is operating on the hood, everything happens the other way around. When the two modes are used together, both slots remain open.

Product characteristics

After choosing a distributor, you should evaluate the desired model according to the following parameters:

- diameter of the splitter plate;

- the size of the holes-slots;

- optimal valve travel.

The working diameter of the head of the installed diffuser is selected in accordance with the standard size of the ventilation duct.On boxes of 100 mm, for example, a switchgear with the appropriate size is installed. The standard values for this parameter range from 80-200 mm. If it is necessary to close off a ventilation duct with a larger cross-section, conventional diffusers are used.

The size of the slot affects the throughput of the entire switchgear, and the margin along the way of the check valve determines the range of its opening when the divisors move along the normal. The higher this indicator, the wider the scope of the anemostat action. The extreme values of the limits of adjustment in various models are from 8 to 30 mm.

Criterias of choice

When selecting the required model, the following device parameters are taken into account:

- the material from which it is made;

- working dimensions of the device;

- the spread of the dimensions of the plates;

- the area of the slots controlling the work.

All these indicators are selected taking into account the peculiarities of operation.

Lightweight materials are used in the manufacture of anemostats: aluminum, galvanized steel or plastic. Elite samples of products are made from wood blanks. The use of each of these names has its positive and negative sides.

Metal

The metal exhaust diffuser and its varieties are characterized by increased wear resistance and long service life. Added to this is an attractive exterior design that is combined with modern style solutions in the interior of the kitchen. The disadvantages include the complexity of installation and high cost. The material is ideally suited for specific production conditions where highly heated air is required to be removed and supplied. Heat-resistant diffusers are installed in smoke removal systems, stainless steel products are in demand in baths, saunas and combustion chambers.

Plastic and wood

Plastic counterparts are more suitable for domestic use, in shopping centers, offices and ventilation systems in public buildings. These products are also used in wet areas: showers, laundries, bathrooms, kitchens and swimming pools.

The advantages of polymer-based anemostats include:

- increased resistance to moisture;

- lightness of material and ease of installation;

- variety of sizes and colors;

- ease of care and maintenance;

- relatively low cost.

The disadvantages of plastic products are considered to be low strength and the inability to work in high temperatures.

Wooden specimens are extremely rare. They are in demand when the design of the kitchen requires it. Such devices are ideal for baths, saunas and other wooden buildings.

Installation of anemostat

The procedure for installing the device with your own hands can be represented by the following sequence of actions:

- From the main outlet of the ventilation system, a section of a flexible air duct is supplied to the area of the proposed installation of the divider.

- A hole is punched in the ceiling with a diameter corresponding to the size of the diffuser.

- The nozzle outgoing from the device is connected to the tubular base of the air duct.

- The outer part is fixed with self-tapping screws of a suitable standard size.

When installing automatic models, you will additionally need an electrical cable connection and a switch installation. At the final stage of work, the support part of the divider is placed inside the serviced air duct and securely fixed. A plate supplied with the device is attached to it by means of self-tapping screws.

Overview of some models

On the domestic market of ventilation systems, devices are represented by many models from various manufacturers, including anemostats with electric motors. The sales leader is the products from the Vents firm.At the same time, products from such well-known manufacturers as Dospel, Blauberg, Systemair and Lessar are very popular.

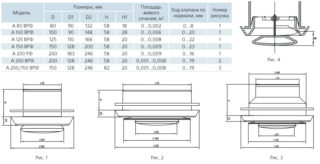

The difference between products from the Vents lineup is manifested in their design features. Among them are widely represented anemostats with a flange (series A 100 VRF) and with a special limiting ring, thanks to which it is possible to fix the distributor without unnecessary trouble. Models marked А200ВР, А200ВРФ and А200 / 150ВРФ are provided with two regulating elements that guarantee effective redistribution of air flows.

Supply air diffusers of rectangular shape under the designations A * PR and A * PRF are produced in two versions with diameters of 150 and 200 millimeters. The cross-sectional area of these varieties is 0.011 and 0.012 square meters, and the normal travel of the plate is 21 and 22 mm.

Prices for Vents models range from 4 to 9 euros.

Metal models of universal or combined devices ("AM * VRF" and "AM * VRF N") are presented on the Russian market with standard sizes of 100, 125, 150 and 200 millimeters. The valve travel range for these products is 2-22 mm.

Air distributors from Dospel (Poland) are presented in three different categories:

- AN * - plastic air inlets;

- ANM * EV - metal exhaust air diffusers;

- ANM * SV - supply version of the previous type.

The diffusers of the AN series air diffusers are available in diameters of 100, 125 and 150 millimeters. The maximum value of the opening value of the adjusting flaps for these models reaches 16, 13 and 21 millimeters.