The extreme "black" way of heating a sauna, when all the smoke from burnt wood remains in the steam room, and carbon monoxide has to be eroded for hours, is a thing of the past long ago. Often, unknowingly, chimneys for a bath are built with gross violations of technology, which lead to fires and poisoning. In order to avoid mistakes, it is necessary to familiarize yourself with the rules for arranging structures that remove combustion products.

- Requirements for smoke exhaust ducts

- Design options

- Components of the external chimney

- Internal chimney device

- Chimney materials

- Metal

- Brick

- Asbestos cement

- Ceramics

- Polymer products

- Thermal insulation of chimneys for a bath

- Mineral wool

- Other thermal insulation materials

- Self-build sequence

- What tool do you need

- Important parameters of the chimney

- Installation features

- Potential errors and maintenance

Requirements for smoke exhaust ducts

Safety measures and microclimate parameters for rooms with stove heating are determined by the Code of Rules (hereinafter - SP) 60.13330 of 2016. The document is called "Heating, Ventilation and Air Conditioning".

The text contains the requirements of laws governing design, construction, as well as the operation of buildings, reflects measures to comply with fire safety and energy conservation. The joint venture gives precise instructions on the observance of the conditions for living, finding, working people.

Compliance with the rules is mandatory for newly built and reconstructed buildings, with overhaul.

You cannot ignore the norms in private households - fires and carbon monoxide poisoning kill thousands of people every year.

The joint venture describes in detail how to correctly lead out chimneys for a sauna stove through the ceiling of the ceiling and walls, what material is safe during construction.

Design options

The same requirements are imposed on any chimney of stoves. Chimneys in the bath must provide:

- effective removal of combustion products;

- lack of toxic substances;

- minimal likelihood of reverse thrust;

- energy saving and energy efficiency;

- ease of maintenance and periodic maintenance;

- fire safety;

- minimal risk of burns.

By the type of construction, external, internal and chimneys in the walls are distinguished.

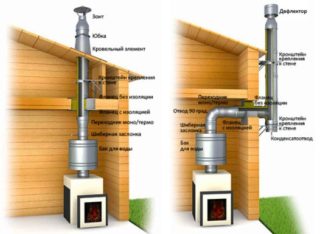

Components of the external chimney

The design received this name, since the main pipe runs outside the walls of the bath.

The external chimney consists of three sections:

- vertical, collecting combustion products from the furnace;

- horizontal or inclined, necessary to bring the pipe to the street;

- vertical, passing along the outer wall.

Advantages of an external gas discharge circuit:

- High degree of protection against fires - the heated chimney does not pass through the ceiling of the steam room and the roof.

- Ease of construction of sandwich structures - parts of the same type are combined in a short time, there is no need to adjust the dimensions of the parts.

- No costs for thermal insulation when crossing the floor.

- The minimum occupied space inside the bath.

Street location also has disadvantages. In cold weather, condensate actively flows down the inner surface, which accelerates the corrosion of metal pipes, destroys brick structures. Ash, while cooling down in the chimney, does not burn completely and is actively deposited on its inner walls in the form of carbon deposits.

Opening ash pans are purchased from the accessories, which are installed at the bottom of the system. The part provides easy removal of unburned residues.

If the owner is interested in an attractive appearance, additional costs will be required for the purchase of factory-made pipes.

Internal chimney device

At the internal chimney, only a small part is outside the bath. The combustion products are discharged vertically upward - the pipe passes through the ceiling and roof. No cornering improves traction. Most of the structure is located inside the room, accelerating the heating of the steam room and adjacent rooms.

The slight temperature difference between the inner and outer surface of the pipe reduces the amount of condensation.

The internal chimney makes increased demands on the thermal insulation of the transition points through flammable ceilings.

The reliability of the building between the ceiling and the roof is approached with great responsibility - you can detect a fire when the fire can no longer be extinguished.

The mixed type includes smoke exhaust ducts passing inside the walls. Such structures are applicable for brick baths, are complex in design, and require thick walls. In private construction, the mixed type is rare.

Chimney materials

Modern industry has established the production of various materials suitable for the manufacture of channels for the removal of combustion products.

Clause 6.6.13 of SNiP 41-01-2003 permits the use of heat-resistant concrete, refractory bricks, asbestos cement and sandwich structures made of stainless steel in the manufacture of pipes. Installation of chimneys from other materials violates the requirements of the document. The owner is responsible for any possible damage.

Metal

Pipes made of ferrous metal are inexpensive, but they are not very suitable for the chimney of the stove.

Single-wall products:

- Warm up quickly to dangerous temperatures. Hot walls can ignite adjacent materials, touching them with severe burns.

- Thick-walled pipes are inconvenient to install due to their large mass.

- Thin metal products burn out quickly and will need to be replaced.

- Condensation forms inside the pipe, which accelerates the formation of through holes. Carbon monoxide flows freely into the room.

The Code of Rules allows the use of stainless steel chimneys for the bath only.

Low cost is the only important advantage of a single wall pipe.

Brick

The rules allow the use of ceramic and refractory bricks. Chimneys inside the bath are most often built from such material.

For self-production of external channels, a brick is less suitable:

- The conclusion of the chimney through the wall is within the power of experienced stove-makers.

- An additional foundation is required for a massive structure.

- A layer of soot is deposited on the rough inner walls, the removal of which will require additional labor costs.

- Part of the heat is spent on heating the pipe, which is not energy efficient.

- Without additional protection of the outer layer, brickwork is rapidly destroyed with frequent alternation of heating and freezing cycles, which happens if the bath is heated from time to time.

A plus can be the appearance of the pipe, built by master masons.

Asbestos cement

The advantage of the material is its low cost. Accurate geometric dimensions and the ability to cut without the use of special tools simplify installation.

Asbestos cement products are more often used for the manufacture of internal channels.

The industry produces only couplings, so making chimney turns is problematic.

Another application is the assembly of the outer part of the chimney, after the combustion products have already been discharged through the wall to the street.

An external chimney from an asbestos-cement pipe must be insulated, otherwise the porous structure of the material absorbs condensate, which gradually destroys the pipe in winter.

Insulation will require the creation of a multi-layer structure, which dramatically increases the final cost, which approaches the price of sandwich pipes.

Ceramics

Ceramic chimney pipes are durable, easy to clean. Due to the low thermal conductivity, a minimum of condensation falls on the inside.

Ceramic chimneys serve as the inner layer of brick or foam block channels. It is impossible to make a chimney only from ceramics.

Polymer products

The advertised concept of "polymer chimney" means just a liner in the pipe.

The polymer channel is not damaged by high temperature, easily bends, which makes installation easier.

The maximum operating temperature is 250 ºС. This means that it is impossible to attach a polymer pipe directly to the furnace; an adapter is required - a metal pipe.

The main purpose of polymer pipes is the removal of combustion products from fireplaces and gas water heaters.

Thermal insulation of chimneys for a bath

Single wall pipes have three main disadvantages:

- strong heat that can cause fire or burns;

- temperature difference between the outer and inner surfaces of the pipe, leading to condensation and increased wear of components;

- increased heat transfer into space, especially for external structures.

To prevent undesirable consequences, chimneys are insulated using various materials. The requirement is mandatory in accordance with clause 4.4.4 of SNiP 41-01-2003.

Mineral wool

Minvata is a common name for several materials:

- stone made from basalt rock;

- glass, produced from broken glass container production;

- slag from by-products of the metallurgical industry.

The use of mineral wool is limited for each type:

- Glass wool, when wet, loses its insulating properties. The material is not technologically advanced during installation - increased measures of protection of the respiratory system and eyes are required.

- Slag wool, when heated, emits harmful substances and is unsuitable for indoor insulation. When wet, it quickly cakes, becomes useless as a heater.

Any wool, including stone, is protected from precipitation. Pipes are wrapped with sheets of material, secured with steel clamps and covered with an outer layer - tin sheets, brickwork, etc.

Other thermal insulation materials

Basalt cardboard Is a material similar to stone wool, a substance for bonding fibers, in which bentonite (a special type of clay) is. The material is safe for nature and humans.

There are two types of basalt cardboard - with or without an additional layer of foil.

The structure and thickness of the sheets are suitable for thermal insulation of the wall.

Fireproof drywall outwardly does not differ from the usual, but the surface of the sheet is impregnated with a fire retardant. The material is used to protect the wooden wall cladding, from heating by the chimney.

Glass-magnesium (glass-magnesite) sheets consist of five layers: a central heat filler, closed on both sides by external decorative layers and a reinforcing mesh.

The flexibility of the material makes it possible to protect geometrically complex surfaces.

Minerite made on the basis of cement and fiber reinforcing material. Plates do not emit toxic substances, well insulate surfaces from heating and detain extraneous sounds. The material is suitable for enclosing combustible surfaces, and is suitable for insulating pipe passages through walls and ceilings.

Self-build sequence

The construction of a chimney duct consists of several sequential operations, each of which is important.

There are stages:

- choice of design: external, internal;

- design based on geometric dimensions;

- preparation of building materials and tools;

- direct construction;

A trial heating and elimination of the identified deficiencies completes the process.

What tool do you need

A set of necessary accessories and tools is usually in the arsenal of a home craftsman. Powerful specialized electrical appliances, such as a jackhammer for making holes in brick walls, are more profitable to rent.

The list of tools includes:

- Devices for making a hole for a chimney - the choice depends on the material of the walls, ceiling.

- Rotary hammer or drill with impact function.

- Angle grinder.

- Hammer, tape measure, plumb line, level, set of screwdrivers.

- Stepladder or scaffolding for work at height.

- Mason's set: mortar container, shovel, trowel.

Electricity supply is carried out before the start of work. Pay attention to the integrity of the wire and the cross section sufficient for the operation of a powerful power tool.

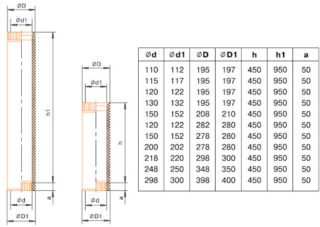

Important parameters of the chimney

Smoke and unburned soot are completely removed to the atmosphere with the correct choice of channel characteristics.

Critical important parameters:

- inner diameter;

- pipe height to create thrust;

- minimum number of turns.

Currently, SP 7.13130.2013 is in force, which regulates the rules for using stove heating in terms of fire protection measures. Failure to comply with the set of rules entails administrative responsibility.

The design takes into account the minimum requirements for the use of solid fuel furnaces:

- the stove should not heat more than 3 adjacent rooms;

- it is forbidden to use ventilation ducts for chimney;

- the minimum allowable pipe diameter for the chimney into the bath depends on the furnace power: less than 3.5 kW - 140x140 mm, 3.5 - 5.2 kW - 140x200, from 5.2 to 7 kW - 140x270 mm;

- the passage in the valves is at least 15x15 cm;

- the minimum distance from the pipe to the combustible walls is 260 mm, for structures made of bricks, blocks or concrete 200 mm;

- the distance to the walls should ensure the laying of a layer of heat insulator of such a thickness that the surface temperature of the building structure does not exceed 40 ° C.

The project must take into account the requirements for the location of the gas outlet:

- the height of the pipe should not be lower than 5 m from the grate of the furnace to the upper point, the cut should protrude 50 cm above the ridge;

- it is allowed to divert pipes from the vertical axis at an angle of no more than 30 °;

- inclined segments can only be smooth-walled;

- the length of horizontal bends is not more than 1 m;

- the number of turns is not more than 3.

Given these requirements, they draw a diagram or prepare a drawing that will help calculate the required amount of building materials.

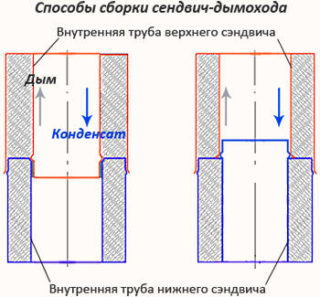

Installation features

The installation of internal chimneys requires special attention to several operations:

- The assembly of sectional pipes is carried out in the direction of the condensate drainage - the narrow part of the upper section is inserted into the socket of the lower pipe. It is recommended to additionally protect the joints with a heat-resistant sealant.

- When passing through the floors, a heat-shielding box must be made, 40 cm larger than the outer diameter of the pipe. After installing the channel, the voids are filled with heat-insulating material. Builders and salespeople refer to the element as "butchery".

- The top and bottom of the box are covered with galvanized iron.

- The walls next to and above the stove are protected with heat-insulating plates.

- Wooden roof sheathing is cut through.

- Provide for waterproofing the roof.

- The overhang of the roof (for outdoor systems) is bypassed at angles of 30 and 45 degrees.

- The cut is protected with an umbrella or deflector.

When entering the chimney through the wall, special attention is paid to the thermal insulation of the pipe.

Potential errors and maintenance

When arranging a chimney, mistakes are often made that affect the durability and safety of use:

- smoke assembly leads to rapid destruction, as condensate enters the gaps between the sections;

- use of prohibited materials;

- the location of the pipe close to building structures;

- non-observance of parameters - height, tilt angles, internal section, etc.

The chimney requires constant attention:

- conduct regular inspections to identify through holes or cracks through which carbon monoxide enters the premises;

- the inner part is cleaned of carbon deposits and soot accumulations as necessary.

Independent installation of the chimney is carried out in compliance with the rules and regulations. In this case, the structure will fulfill the assigned functions, it will be safe and durable. If you have doubts about your abilities, it is better to contact a specialized organization.