The ventilation grill is the most visible element of the air distribution system. It has many important tasks. The lattices differ from each other in color, shape, size, material. In this variety, the simplest plastic stampings are adjacent to electrically heated devices.

Ventilation grilles

The frame, which provides rigidity, is the backbone of any ventilation grill. The frame is fixed to the wall or built into the duct. Frames of large gratings are divided into sectors. This increases the strength required for eg basement ventilation.

The working area of the device is covered with a removable panel or movable blades. Depending on the type of panel, distributors are:

- undirected action. The air flow passes through them unhindered. They are mostly decorative;

- directional action (adjustable).

The blades are positioned horizontally, allowing the louvers on the ventilation grill to change the direction and intensity of the air flow. The cover plate can be removed for cleaning. On the inside, all decorative overhead ventilation grilles are covered with a mosquito net, which can be removed if necessary.

More sophisticated devices are equipped with shut-off valves... The ventilation grill with a valve protects against backdraft, insects and dust. The valve works automatically, letting air through the grill only to the outside.

A similar function is performed by blinds of inertial or gravity type... Functionally, they can be called an analogue of a ventilation grill with a check valve, where the air flow is blocked by movable horizontal strips. Lightweight materials such as aluminum or PVC are used in the manufacture of ventilation grilles with gravity blades. Gravity grilles are installed on the chimney.

If necessary, the movement of the air flow is completely blocked by a ventilation grill with a damper. These models are indispensable in steam rooms and saunas.

Lattice shapes and materials

On the shelves of hardware stores, you can find rectangular, round and square grates. Such forms harmoniously fit into the interior. Sometimes fancy-shaped lattices are made on special orders. Usually these are distributors for luxury cottages or fireplace grates. Such products are made in the same style as the design of the room and can be of a wide variety of colors, shapes and even from unusual materials, for example, ceramics. For the production of air distributors use:

- aluminum alloys;

- Cink Steel;

- brass;

- plastic;

- wood;

- ceramics.

Aluminum ventilation grilles They are lightweight, resistant to moisture, active substances. Therefore, they are used in the construction of industrial and residential buildings. The ventilation grilles made of aluminum and other metals are additionally resistant to a special coating: powder paint of various shades.

The only drawback of these universal products, which narrows the range of their application, is the high price.

Metal ventilation grilles are widely used in industrial ventilation. Ventilation grilles made of metal can withstand powerful air pressure, aggressive substances and particles. Such grilles are reliable and durable, therefore, the external ventilation elements are always made of metal. External ventilation grilles are coated with special especially resistant compounds to prevent corrosion.

Disadvantages of metal gratings: heavy weight, high price.

Plastic ventilation grilles made from polystyrene or polyvinyl chloride, installed on ceilings, walls, doors. Initially, they are usually white in color, which can be applied with any colorant from a spray can. Plastic ventilation grilles are installed in the ventilation of apartments, cottages, offices. Round plastic ventilation grilles resemble ceiling lights and are therefore often installed on complex multi-level ceilings. Adjustable circular ventilation grilles are called diffusers.

Disadvantages of plastic ventilation grilles: after a while they turn yellow, the smoothness of the surface is lost.

Wooden ventilation grilles - these are most often modifications with valves for baths and saunas or decorative items of individual design. Sustainable wood is becoming more and more popular, and ventilation grilles with a shutter perfectly complement the interior.

Disadvantages of wooden gratings: they are not cheap and require periodic treatments with special compounds.

Exhaust grille types

PVC and metal ventilation grilles are installed on air ducts for various purposes:

- supply air;

- exhaust.

The place of installation determines the type of product:

- internal;

- outdoor ventilation grilles;

- overflow.

The most popular types of ventilation grilles

There are many types of ventilation grilles in construction stores: round, rectangular, external and internal.

Outdoor supply air

External ventilation grilles are presented in the following options:

- Frontal grille specially designed for ventilation of attics. It is always carried out with a wide edging, which makes it more decorative;

- Basement ventilation grilles with dimensions of 15x15 cm, 24x24 cm, 37.5x37.5 centimeters must be reliable and protect the basement from rodents;

- Door ventilation grilles used instead of a supply valve, if there are no other ways to organize the supply of air to the house;

- Floor ventilation grilles indispensable for the organization of the inflow, displacing the exhaust air from the bottom up. Floor ventilation grilles can be adjustable and stationary. In the first case, blinds are inserted into the metal frame, which can be rolled up.

| Lattice name | Installation locations | Functions | Additional features |

| Internal | Outlet of supply and exhaust air ducts in the room | 1. Correction of the direction and intensity of air flows. 2. Room design | Blinds, latches |

| Outdoor | External outlet for air ducts of any type | 1. Protection against ingress of birds, mice, dry leaves into the air ducts. 2. Decorative function | 1. Heating to avoid ice build-up in winter, 2. Dampers, gates, blinds. |

| Transfer | Interior partitions and doors | Ensuring free movement of air in the room | Sound and light insulation, blinds |

Table 1. Main characteristics of ventilation grilles

Internal exhaust

- Surface-mounted ventilation grill used in living quarters equipped with natural draft. The mosquito blanket protects the apartment from insects. If the ventilation grill is equipped with a non-return valve, the occupants are not at risk of reverse draft. Ventilation grilles with or without blinds are installed in kitchens and bathrooms. The throughput of the ventilation grill is regulated by movable strips;

- Ventilation grill with valve and kitchen hood connection... They are made of PVC, can be equipped with a check valve or inertial blinds. Simultaneously provide natural draft and air outflow from the cooker hood;

- Slotted ventilation grilles installed where ventilation should be invisible. The dimensions of the ventilation grilles are matched to the ceiling design and are hidden between levels or decorative elements.

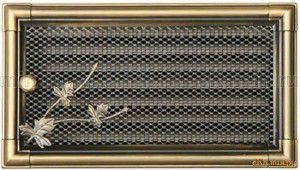

Internal supply

Internal supply grilles are made of various shapes and colors, sometimes with attractive designs. The round shape of ventilation grilles is popular among architects as the most harmonious and invisible. Supply ventilation grilles are never equipped with valves. Designer pieces are created using manual woodworking, forged elements, laser cutting. Through fireplace ventilation grilles the air in the hall is warmed up. The cold convective flow enters the fireplace through the lower grate and enters the room when warmed up through the upper one. Therefore, a pair of ventilation grilles must be located in the fireplace channel.

Ventilation grilles for fireplaces are made only of refractory and infusible materials. They can be categorized as decorative ventilation grilles for their variety of colors and ornaments.

Ventilation grill installation

Installation of a ventilation grill is not very difficult even for a novice home craftsman. We offer several mounting options:

- Ventilation grille frame is installed directly into the duct and fixed dowels to Wall. In order to avoid rattling in the future, the connection is sealed with a rubber gasket;

- As fasteners you can use liquid nails, silicone or mounting glue... The entire perimeter of the mesh is carefully processed with glue. The ventilation grill is applied and glued only to a dry wall. For a day, the structure is fixed with paper tape;

- Quickly and conveniently, the aluminum ventilation grill is installed on spacer spring partsthat come with some models. The advantage of such fasteners is the ability to remove and install the grille several times. But the springs will not press the grille tightly enough against the opening unless it is fitted with a properly sized mounting frame.

The most reliable way of attaching ventilation grilles is with various connectors. The largest and heaviest grilles are installed on latches or wraps. The fasteners are not visible, but first, a counter frame must be inserted into the opening.

Video instructions for installing a laid-on plastic ventilation grill:

We need a lattice in the attic, size 40 * 60

You need a so-called "front grill". They are selected based on the appearance, the size is standard for all.