Ventilation in the bath is necessary, since it is built in such a way as to make it as tight as possible. The high temperature and humidity of the air contribute to the formation of mold, and the lack of oxygen prevents the normal combustion in the stove and the breathing of people during bath procedures. It is especially important to have an effective ventilation system when using gas and solid fuel stoves. Thanks to high-quality ventilation, the flow of fresh air is provided, the microclimate is normalized, the wood remains unchanged: it does not rot and does not become moldy, unpleasant odors are eliminated.

- Types of ventilation

- Natural

- Forced

- Combined

- General rules and nuances when planning ventilation in a bath

- Firebox in an adjacent room

- Heating chamber inside the steam room

- Operating ventilation systems

- Inflow near the furnace

- Blower as a hood

- For a bath with a wet floor

- Openings in one wall

- Recommendations for arranging ventilation

- Adjustment during use

Types of ventilation

The principle of arranging ventilation in a bath and a sauna is to organize a supply and exhaust system. For this purpose, two holes are made: an inflow and an outflow. Fresh air of lower temperature displaces heated air.

You cannot make an inflow from the premises, for example, a dressing room, and an outflow to the street, or vice versa. Due to the temperature difference, such a system will not work properly. You can make the entrance and exit to the dressing room, but experts recommend that both of these openings face the street.

There are three ventilation options based on the principle of operation.

Natural

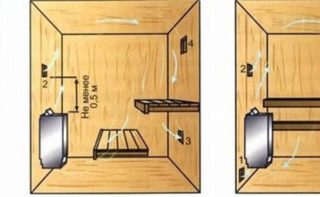

Such a system is highly efficient, profitable and works due to the difference in temperature and atmospheric pressure. The location of the holes is determined based on the size of the steam room and the place of installation of the stove, shelves, material of the walls of the bath. According to the general rules, the inflow in the bath is done at the bottom, and the hood is at the top.

Forced

Benefits of forced ventilation:

- maintaining the set temperature and humidity level;

- even distribution of heated air masses;

- accelerated air exchange;

- independence from weather conditions;

- the ability to install air filters.

Forced exhaust ventilation is optimal for quick drying and ventilation.

The risk of short circuits and fires due to wiring in a wet room increases.

Installation of forced ventilation is recommended in the following cases:

- The steam room (bath) has a large area.

- The bathhouse is built of bricks, foam blocks.

- Cannot place the inlet and outlet correctly.

- Powerful oven.

There are no particular difficulties during the installation of equipment, but when purchasing forced ventilation, it is necessary to check that the device has maximum protection against moisture.

Combined

Combines the advantages of natural and forced ventilation. A fan is installed in the exhaust hole.In order to have the possibility of natural inflow, it is necessary to arrange the inflow and outflow in accordance with the rules, then the streams of hot and cold air will mix.

The disadvantage of combined ventilation in the steam room is that in order to regulate the air exchange, the exhaust opening will sometimes need to be covered with a damper. This creates an unwanted load on the fan. If the hole is not covered, the room will have to be heated more intensively to maintain the high temperature.

General rules and nuances when planning ventilation in a bath

When planning ventilation in the bath, it is necessary to determine the location of the holes. The larger they are, the faster the bath will be ventilated. The inlet and outlet in the bath are equipped with control valves. When closed, they must ensure tightness.

The difference in the diameters of the inlet and outlet openings does not affect the operation of ventilation. If the outlet passes 1 m³ of warm air per hour, exactly the same amount of cold air will be drawn into the room, only the flow rate with a narrower inlet will be higher. The backdraft effect occurs if the wind blows into the wall from the side of the exhaust outlet or the inlet is closed.

When planning forced ventilation in the steam room, it is necessary to accurately calculate the fan performance. If it turns out to be too powerful, the air exchange will be too intense. To calculate the performance, you need to find the volume of the room by multiplying the area by the height of the ceilings, and multiply the resulting value by the recommended air exchange rate. For baths, this figure is five.

If it is necessary to subsequently reduce the ventilation intensity, you can set a timer so that the fan turns off at regular intervals.

Firebox in an adjacent room

The firebox is taken out into a room adjacent to the steam room - a dressing room or a rest room. This placement has its advantages:

- In the rest room, you can arrange a semblance of a fireplace by closing the firebox instead of the door with heat-resistant glass.

- The firebox heats not only the steam room, but also the adjacent room.

- It is convenient to allocate a place for storing firewood in the rest room or dressing room.

- The steam room does not accumulate dirt and debris.

At the same time, the heating and ventilation device has some features. The furnace is connected to the furnace using a furnace tunnel. It is laid through an opening in the wall, performing thorough thermal insulation with basalt wool.

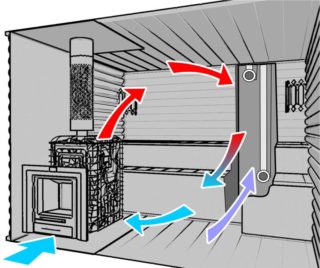

The inlet is made closer to the floor, placing the end of the duct at the bottom of the firebox, at a distance of several centimeters from the metal sheet that protects the floor from fire. Supply ventilation in the steam room will work due to the ventilation ducts of the furnace and the supply air duct. The exhaust outlet is best placed on the opposite wall, 30 cm from the ceiling. It is recommended to make another hole under the shelves. Both holes must be connected with a vertical duct. The lower hood is slightly opened when taking procedures in the steam room, the upper one is closed at this moment. It is such a system that will save heat and at the same time provide ventilation.

Heating chamber inside the steam room

If the firebox is located inside the steam room, the principle remains the same, but the supply ventilation scheme changes. It is necessary to equip the inflow channel in order to maintain the combustion process. The ventilation system is controlled by two doors located one above the other. First, open the bottom, cold air does not enter. When the oven is warmed up, the top door is slightly opened. The air in the steam room will circulate through the doors, gradually heating up more and more.When the temperature in the steam room is acceptable, the lower door is closed and the upper door is left open. After fully warming up, close both doors.

Operating ventilation systems

There are several rules and schemes for ventilation in the bath. Their effectiveness has been proven by numerous examples from practice.

Inflow near the furnace

The ventilation opening can be located next to, under or behind the oven, at a distance of 25-35 cm from the floor. Direction of flow: along the floor and then along the opposite wall. If the inflow is located behind the stove, the oxygen inflow will promote vigorous combustion.

Blower as a hood

The stove can perform the main function in the ventilation system. Effective ventilation is ensured by exhausting air from the steam room through a blower. In this case, the furnace is installed below the level of the finished floor.

The heated air will be removed through the chimney, and it can enter the steam room in different ways:

- through the ajar door;

- through the hole at the bottom of the door, which is closed with a decorative grill;

- through the cracks in the floor;

- through the window.

In the latter case, an uncomfortable microclimate can be created in the steam room, since the window leaf is usually located above the firebox, and the heater is at the opposite wall. Cold air will "cut" the steam, heading for the exhaust port, without having time to heat up.

The advantage is that the ventilation speed is controlled by opening and closing the oven doors. So that the air entering the room has time to warm up, the inlet must be placed behind the stove.

Disadvantages:

- the presence of dead zones;

- dependence on weather conditions;

- low productivity.

The blower as a hood is suitable only for a small bath.

For a bath with a wet floor

In a bath with a leaking floor, where the top layer is represented by a grate, there is a high risk of decay of the floorboards and the spread of mold, since steam, moisture from the ground and foundation, and condensation affect the wooden flooring. In this case, it is important to place the holes under the floorboards, in the wall or in the foundation. When airing, the upper surface of the floor will dry, and when the hood is opened, the lower surface. At the same time, it is advisable to provide for the drainage of water outside the bath when developing the project. Ventilation can be natural or forced. Despite the high efficiency of the system, no drafts are generated.

Openings in one wall

This placement is not the most successful, but it takes place if other options are not suitable. For example, the inflow and outflow on one wall is done if the other surfaces are adjacent to residential buildings. In this case, a fan must be installed on the exhaust outlet.

Recommendations for arranging ventilation

Since a bathhouse is a series of interconnecting rooms, the problem of ventilation is relevant for each of them.

- In the attic, an inlet should be made under the canopy of the roof, and the hood should be on the ridge.

- It is best to organize forced ventilation in the washing compartment, thanks to which excess moisture will not accumulate.

- In the shower compartment, it is enough to make air vents under the ceiling.

If each of the rooms is equipped with supply and exhaust openings, dampness can be avoided.

Since the dressing room is located next to the steam room, steam also penetrates here, condensation forms on the walls. Here you can design ventilation of a similar type or simply make windows that will allow you to quickly ventilate the room.

Adjustment during use

A correctly calculated and equipped ventilation system is still half the battle. If you do not know how to use it, there will be little sense from it.

Step by step guide:

- When the oven just starts to melt, all openings - both supply and exhaust - are closed.

- If the temperature in the steam room has reached the desired values, you need to slightly open the doors of the stove or dampers.

- The more fresh air is required, the more openings are opened.

- When airing the steam room after the procedures, the valves are fully opened.

The principle of adjusting the ventilation system when the firebox is located in the steam room is somewhat different.

Thanks to a carefully designed ventilation system, it is possible to create a comfortable microclimate in the steam room and protect the tree from mold and rot. The regulation ensures a constant supply of fresh air during bathing procedures and at the same time preserves heat.