One of the aspects of human health is a favorable microclimate. Comfortable temperature, room humidity and air purity are of great importance. The purification system plays an important role here. This is all the more relevant in connection with the use of building materials that clog the internal space. Ventilation in a private house with wall access helps maintain a healthy living environment.

- Common ventilation problems

- Organization of ventilation with access to the wall

- Natural extraction

- Forced action settings

- Combined ventilation device

- How to calculate a wall exhaust

- Installation in premises for various purposes

- Range hood in the kitchen

- Ventilation in the toilet and bathroom

- Channel laying in a concrete wall

- Advantages and disadvantages of outdoor hoods

Common ventilation problems

Due to the rising cost of energy, homeowners are trying to reduce their costs through the use of energy-efficient technologies. To reduce heat loss, plastic windows and doors with airtight gaskets are installed everywhere. Achieving a positive effect in the field of saving heat, people lose in another area - in the natural circulation of air masses through microcracks and cracks in building structures.

The next factor of insufficient filtration ventilation in houses where air handling units are installed is their incorrect organization. It may consist in insufficient power in terms of the area of the building and in poor-quality installation of lines. As a result, due to low efficiency, not the entire volume of air inside the house will be renewed in time.

The result of all this is increased humidity, accumulation of harmful gases and the development of pathogenic microflora in private housing construction. Damage to interior finishing materials is the most harmless thing that can happen, more dangerous is the aggravation of respiratory viral diseases and allergic reactions.

Organization of ventilation with access to the wall

The life support system of housing construction in terms of filtering and ventilation cannot be built on any one principle. An integrated approach is important here. Constant air exchange can only be ensured if there is sufficient air flow. Therefore, natural paths for the penetration of clean air and ventilation in the forced wall are important. In the first case, we are talking about airing the house by opening windows.

In winter, when the temperature difference in the house and outside is significant, the traction capacity of the filter ventilation is much higher than in the warm season.

Natural extraction

Natural exhaust is understood as a set of measures for the organization of exhaust ducts without the use of forced fans. Due to their low performance and depending on the weather conditions outside, such systems need good air flow. When equipping a house with a natural ventilation pipe, it is necessary to think about its outlet to each room of the building and about equipping such spaces with supply valves that are installed on the wall opposite the exhaust hole.

Natural filtration ventilation is more beneficial for the human body, since the movement of the mass flow does not create unwanted drafts. The pumped volume is in the range of 0.9-0.7 cubic meters per hour.

Forced action settings

Compared to natural cleaning, the forced draft through the wall into the street has an electric motor with an impeller, which sucks exhaust air out of the apartment. Depending on the area of a particular room or the entire building as a whole, such units may have different performance. A full-fledged circuit is also equipped with supply fans, pumping the masses from the street inside, which work simultaneously with the exhaust fans.

The speed of movement of the air flow in the house in such conditions reaches 5.5 - 3 cubic meters per hour, which is felt as a light breeze. Therefore, such settings can be uncomfortable for particularly sensitive people.

A forced supply and exhaust cleaning device can be equipped with a separate room or the whole house by laying multi-channel shafts.

Combined ventilation device

The mixed filtration ventilation scheme is based on the principle of laying a network of branched hoses for natural convection of air masses and equipping individual rooms with supply valves. In addition to all this, in places of the greatest accumulation of vapors and moisture, forced ventilation is organized through the wall to the street in the form of overhead appliances.

Such a system is the most productive, as it allows a flexible approach to the issue of cleaning. With good external traction, you can not use electrical equipment, thereby saving money.

How to calculate a wall exhaust

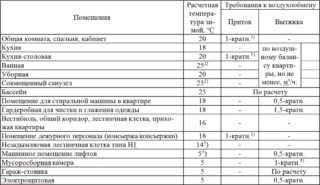

The simplest calculation of the filtration and ventilation of a private house comes down to determining the performance of the electrical equipment required to ensure air exchange. For this, the multiplicity method can be applied. Its essence lies in the fact that for each type of room the volume of air mass must be replaced a certain number of times per unit of time (one hour). The power of an electric fan is also calculated by the ability to pump out a certain volume within an hour. Therefore, to calculate performance, the formula is usedM = n x Vwhere:

- M - calculated fan power;

- n - the frequency of changing the volume of air in the interior space (for each type of room it has its own and is regulated by standards);

- V - the volume of a particular room.

All these calculations are relevant for any type of electrical exhaust equipment:

- axial structure models;

- centrifugal fans;

- in-channel installed devices.

In addition to basic devices, a standard supply and exhaust system may contain supply valves, check valves, round and rectangular pipes, decorative and protective grilles, mosquito nets.

For efficient operation of the equipment, you should take devices with a small margin of performance.

Installation in premises for various purposes

There is no difference in the organization of the technical part of the hood in different types of premises. Everywhere this process is accompanied by laying channels, supplying electricity, installing fans. The difference can only be in the power of the installed equipment and the rules for the outputs of these air ducts relative to the levels of the ceiling, floor and the relative position of the supply and exhaust pipes. All these points are stipulated by building codes and regulations. For the layman, you can consider simplified schemes for organizing the cleaning principle.

Range hood in the kitchen

According to the rules, the ventilation system in the kitchen should be formed on the basis of two exhaust ducts: one local above the stove and a common one, and an air inlet, which can be an ordinary vent.

If the kitchen is equipped with a natural gas stove, the air exchange rate per hour should be about 140 cubic meters. In the case of using an electric hob, this figure can be reduced to 110 cubic meters.

Ventilation in the toilet and bathroom

The minimum parameters of the air exchange capacity in the bathroom and toilet correspond to 50 cubic meters per hour, the maximum reaches 150 cubic meters. All of this applies to standard rooms. Since the places for receiving bath procedures are not always equipped with windows and there is no way to open the window, the air flow must be carried out through the holes in the lower part of the door leaf or through the supply pipes.

The hood inlet must be in close proximity to the source of humidity. In combined bathrooms, the exit must be done both above the bathroom and above the toilet.

Channel laying in a concrete wall

As a rule, it is more expedient to make a passage channel through a concrete wall with a round diameter. Drilling of the material is carried out using diamond cutting, the so-called victorious crowns. The diameter of the crown must be larger than the diameter of the device seat, taking into account the laying of the pipe and insulation on it. In the absence of insulation, condensation may accumulate on the walls of the channel, so it must be laid with a slight slope towards the street, but this only applies to the forced filtering ventilation scheme. The duct material should be made of thermostable plastic or stainless steel. Reinforcement in concrete can be carried out using polyurethane foam.

Advantages and disadvantages of outdoor hoods

Forced scrubbing through the wall allows for efficient air exchange regardless of natural draft conditions. For the organization of the system, as a rule, large labor costs are not required, the energy costs of such equipment are also minimal. Adjustable fans can be easily adjusted to any operating mode.

Among the shortcomings can be noted the presence of a certain noise in the work, slightly felt drafts, dependence on electricity.