Installing a cooker hood in the kitchen is optional and is initiated by the property owners. The presence and use of this technique allows you to absorb most of the steam, heat from the oven, oil and grease vapors. Even if the food on the stove burns, the installation will prevent smoke from forming in the apartment by removing combustion products. Correct installation of the cooker hood will ensure a longer service life of furniture and finishes that are always clean and presentable. Installation of the product is not particularly difficult and can be done independently. A clear diagram, a headset and a description of the fixing rules are attached to the devices. In this case, it is necessary to ensure the inflow of clean air and the removal of exhaust air, otherwise the technique will be useless.

Rules for installing hoods in the kitchen

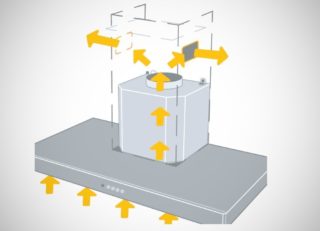

The selection and connection of the hood is carried out based on the layout and size of the room, the location of the stove and the characteristics of the device itself - type, shape, size, weight, set of options. Various models can be hung on the wall or ceiling, built into a headset or worktop. According to the principle of operation, the products are divided into exhaust, where contamination is removed through pipes, and circulation, equipped with filters. In the first case, cleaning is more efficient, but the structures are more difficult to install and require additional investments. It is easier to install a circulation system, but it does not remove heat, does not retain all vapors and moisture.

When installing the hood, it is recommended to adhere to the following rules:

- compliance of the strength of the load-bearing wall or element of the kitchen set with the weight of the product;

- design and size that matches the interior of the room;

- lack of contact with the gas pipe;

- the distance between the hob and the appliance is within 65-80 cm;

- the screen size is equal to or larger than the surface of the slab;

- power, providing high-quality ventilation of the room;

- ease of maintenance and operation;

- the ability to connect yourself.

The person's height should be taken into account. The protruding screen should not be at the level of his head, otherwise cooking will be inconvenient and hazardous to health. But if you attach the technique too high, its effectiveness will decrease. In addition, you will have to use a stool to turn the device on or off.

DIY installation features

Installation in a private house does not imply any significant restrictions, since the owner of the home himself chooses the layout of the object. The choice of design is largely determined by the material from which the building is built and its height.

Installation features:

- Lack of a ventilation shaft. An additional channel must be laid. In this case, you can choose any option that is most suitable from an aesthetic and practical point of view.

- Low building height. Because of this, there is not enough natural draft. It is necessary to install a mechanical system, which in a wooden house is associated with the complexity of laying the electrical network.

- Compliance with fire safety rules. If they were initially taken into account in apartment buildings, then the private owner needs to develop a project on his own.

It is much easier from a technical point of view to install a hood in the kitchen of a city apartment. Initially, the project provides for vertical shafts passing through all levels of the building. You can connect to them without obtaining special permission from the management companies. The owner of the home has to choose the hood, fix it on the base and connect it to the general communication.

In this case, the following nuances should be taken into account:

- Do not carry gas pipes on your own. If there is a need to put the stove in another place, a certified hose can be pulled from the riser to it.

- Ventilation shafts can have different purposes. They serve to remove combustion products, sewage vapors and emissions from living quarters. It is not allowed to connect structures of different purpose in order to prevent the penetration of exhaust gas into the highways passing through the halls and bedrooms.

- To ensure high-quality fasteners in brick houses, it is necessary to use anchor bolts with a thickness of 8-10 mm.

Since island-type hoods are practically not used in city apartments, it is advisable to focus on the technology for assembling products of the built-in, inclined and suspended type.

Site selection and instrument preparation

To install a ventilation system for a cooker, no special skills and special equipment are required.

For work you will need:

- hammer drill, electric drill, jigsaw;

- level, tape measure;

- hammer, screwdriver;

- hacksaw for metal, file;

- adjustable wrench or pliers;

- silicone;

- pencil;

- masking tape;

- construction gloves, goggles;

- tow or FUM tape.

Since you will have to work at a height, it is advisable to prepare a stable base. Then you need to think over the preparatory stage. Before you hang the hood, you need to put it on something. For this, cardboard, plywood or chipboard is suitable.

If an exhaust duct is to be assembled, it is advisable to prepare a small stepladder. It is better to move the slab to the side during installation. This will prevent damage to its surface and cover in the event of a hood or heavy tool falling over.

It is allowed to fix the equipment only on a solid and stable base. This requirement is due not only to the issue of equipment safety. If the product falls, it will rupture the gas pipe and power cable. The combination of fuel and sparks will inevitably cause a fire and even an explosion.

Modern hoods are equipped with fixing strips and decorative boxes for masking pipes, if their design does not match the interior of the kitchen. Thanks to this, it became much easier to install the equipment than it was before, when dowels, screws and hooks were used.

The best option is to integrate the appliances into the kitchen wall. This method saves space. It should be noted that the distance from the appliance to the refrigerator and sink must be at least 50 cm. Such rules are due to the safety requirements for handling electrical appliances.

If the walls are made of plasterboard, you will need to make an installation. Profile pipes made of stainless steel are best suited for this. Metal can not be decorated, but left as it is. If the supporting structure does not fit into the interior, it is painted to match the color of the walls, pasted over with tiles, wallpaper, or enclosed in a homemade box made of non-combustible material.

In large kitchens, the work area is sometimes located in the middle of the room or against the wall opposite the headset. In the first case, an island-type hood with a ceiling mount is selected. The device is equipped with filters or a separate exhaust duct. To hide communications, you can install a stretch ceiling by lowering it 1-2 cm below the duct.In the second case, the best solution would be a wall-mounted chimney hood. To connect it to the ventilation shaft, a duct made of plastic pipes of round, rectangular or square cross-section is used.

The main stages of installing the hood in the kitchen

If safety requirements permit, it is better to install the stove and the hood opposite the outlet to the general ventilation system. If this is not possible, you will have to buy pipes and deal with their laying. The option with filters can be considered as temporary, since the circulation system does not differ in the proper efficiency of air purification and removal of contaminants.

Regardless of the type of equipment, any work begins with unpacking and control inspection. The product may have received internal and external damage during transportation. Then a test run of the device should be carried out in order to check its operability. It often happens that the supplied screws and brackets do not meet the required strength. If their reliability raises even the slightest doubt, the products must be replaced.

Step-by-step installation of mounted models:

- Marking. A vertical line is drawn from the center of the slab and a horizontal line is drawn to mark the bottom of the screen. Then a second horizontal line is made, along which the bracket is attached.

- Suspension installation. First, holes are drilled, then dowels are hammered into them. If there is a layer of protruding apron trim below, a wooden batten with through holes is used to compensate for the vertical drop. The horizontal is checked last and the mounting plate is screwed on.

- Hood hanging. This should be done slowly and carefully so as not to lose balance and not drop the product. The slots on the back cover of the case are aligned with the protrusions on the bar, after which it must be lowered down until it touches the wall.

The final step is to fix the filters in the seats.

Embedded models require more time and effort to install. To build the hood into the wall of the kitchen unit, you will need to perform the following manipulations:

- Check with a level the horizontal of the cabinet to which the equipment will be attached. Correct if necessary.

- Remove the cabinet, disassemble it so as to gain free access to the bottom and lid. It is better to remove the door so that it does not interfere with work.

- Glue the template to the bottom with masking tape, transfer the marks for the holes for the bolts and air duct to it. Repeat the operation on the lid.

- Using a drill and a jigsaw, make holes of the required diameter, treat them with a primer or acrylic paint to protect them from dampness.

- Install the adapter for supplying the ventilation duct to the hood.

- Place the cabinet on the appliance, align the holes, connect the objects.

- Hang the assembled structure on the fasteners on the wall.

- Install the ventilation duct.

A cabinet with a pipe running through it is not a decorative element. It can be used to store dishes, spices and other kitchen items.

Installing the duct

The air duct is designed to remove heat from the stove, food vapors, smoke, moisture and fuel combustion products. The structure is a pipeline, one end of which is connected to the hood, and the other is brought out into the ventilation shaft or outside through a hole in the wall of the house.

There are such options for arranging the duct:

- Aluminum corrugation. The product is inexpensive, easy to install and corrosion resistant. He also has enough minuses. Corrugation makes a lot of noise, dirt accumulates in the folds, aesthetics leaves much to be desired.

- Plastic boxes. Parts are sold with a length of 50-200 cm.The section is round, square and rectangular. Complete with couplings, elbows, adapters and strips.

- Iron pipes. As a rule, they are produced in a square shape with a side size of 10-20 cm. The connection is made in a socket, possibly subsequent decoration for furniture or kitchen decoration.

To assemble an air duct for a kitchen hood, you must perform the following measures:

- Carry out measurements, draw up a drawing of communication. Based on the data received, calculate the required materials.

- Attach a strip to the wall through which the pipe will come out.

- In accordance with the scheme, cut out the fragments of the canal, remove the burrs from the edges, slightly round off the outer corners.

- Assemble the air duct, starting from the hood. Eliminate bugs, if any.

- Disassemble the structure, lay out the fragments in the order of connection.

- Reassemble the duct, but using silicone to seal the joints. Remove excess solution with a damp cloth or sponge.

If the ventilation hole in the kitchen is the only one, it should not be completely covered with a pipe. This will disrupt the circulation of air in the room. In such cases, it is necessary to use a combined grille, where the upper part is covered with a removable mesh, and the lower one is equipped with an opening for the air duct inlet. To prevent the penetration of neighboring odors into the home, it is better to purchase a grill with a check valve.

Cooker hoods are not very powerful and safe in terms of the risk of electric shock. They can be plugged into a standard non-grounded outlet. If the cable is not long enough, it can be replaced or an additional socket can be connected to the device. To mask the cable, a plastic box or pipe is used.