When organizing a ventilation system, it is necessary to calculate the permissible thickness of the air ducts at which they function in normal mode. Installing an air box or pipe with thinner walls will lead to malfunctions. First, it is necessary to understand the conditions in which the elements of ventilation systems are operated in apartment buildings and at other facilities.

Main characteristics of air ducts

In accordance with the normative documents for ventilation, the technical characteristics of the used air ducts must be within the framework of the requirements. In this case, the quality of air purification in the manned premises is considered satisfactory. These requirements relate to the shape, the permissible dimensions of the structures used and the materials from which they are made.

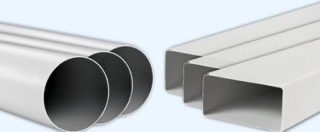

According to the cross-sectional shape, all known types of air ducts are divided into round and rectangular. According to the wall thickness of steel billets, they fit into the following standard row: 1 mm, 1.2 mm, 1.5 mm and 2 mm. There are samples with large indicators (3.0 and even 4.0 mm). One of the main characteristics of these elements is the area of the air channel, which is usually taken into account when choosing its shape.

Round products have a smaller wall thickness, since, all other things being equal, they are able to withstand high pressures. Their cross-sectional area is 12% less than the same indicator for rectangular specimens. When comparing the lengths of the sides, the difference increases to 40%. This allows, without loss of efficiency, instead of one rectangular air exchange channel to make a pair of circular ones, located in parallel.

Duct classification

In accordance with the set of rules for joint venture Ventilation, the air ducts used in these systems are divided according to the following indicators:

- developed internal ultimate pressure;

- the speed of air movement in the supply or waste channels.

In accordance with the first indicator, they are divided into low (less than 900 Pa), medium (900-2000 Pa) and high pressure (over 2000 Pa) air ducts.

According to the speed of air movement in the channel, there are low-speed (less than 15 meters / sec) and high-speed (more than 15 meters / sec).

Low-pressure ventilation systems with relatively low flow rates are installed in small apartments. In rooms of a larger area and especially in high-rise buildings, pipe ducts with high pressure and high permissible air velocities in the air ducts according to SNiP are in demand.

Use of thin steel

Unscrupulous companies in the production of air ducts use steel somewhat thinner than required by the standards in force in Russia. As a result of technological deviations, the walls are thinned by 0.5 or even 1 mm. These violations can be identified at the low cost of the proposed samples, the manufacturers of which are trying to maintain their positions in the competition.

The use of thin metal air ducts is a gross violation of construction technologies and a threat to the health of people at the facility. Ventilation, mounted on the basis of such blanks, quickly deteriorates or will be extremely ineffective. This is due to the fact that strong air currents will quickly destroy the thin walls of the structure and lead to a decrease in the outflow of contaminated masses.

Also, a violation of technology leads to the following undesirable consequences:

- decrease in the efficiency of all equipment;

- unjustified costs of paying for electricity;

- increased noise levels and increased vibrations;

- rapid corrosion of the surfaces of hoods and air ducts.

All these manifestations lead to the need to update the equipment, which will require additional costs or cause downtime of the ventilation network.

Types of materials for boxes and pipes

When choosing a high-quality duct, in addition to the wall thickness, you will need to decide on the metal that is used in the manufacture. The most common types of such materials:

- stainless steel;

- galvanized stainless steel;

- aluminum and its alloys;

- black rolling.

The first two positions are the most suitable for serial production of air ducts. In terms of their strength characteristics, they meet the requirements of current standards and are suitable for use in industrial ventilation networks. The air in the latter is saturated with harmful substances and industrial wastes, which, despite their destructive effect, do not harm pure stainless steel. In accordance with GOST, galvanized steel air ducts are only slightly inferior to the first of the listed materials.

The use of aluminum in the manufacture of air ducts has its positive aspects. Due to the smoothness of the inner surfaces, the air flows in the box are practically unobstructed. The speed of their movement in normal and emergency situations increases significantly.

Features and Benefits of Black Steel

The materials are used when the air transported through the channels has a temperature above 80 degrees. For their manufacture, as a rule, steel rolled products of cold or hot type are selected. In this case, the pipes themselves are made welded, for which the appropriate equipment is used. The thickness of the walls can vary depending on the category of the object on which they are used.

By design, welded black steel air ducts are:

- straight;

- shaped;

- with non-standard contours.

Black steel differs from other materials in its increased fire resistance. Its disadvantages include low corrosion resistance, which forces manufacturers to additionally treat surfaces with a special primer.

Standardized dimensions of air ducts

According to the current standards (SNiP for ventilation 2.04.05-91-2003), the thickness of the walls of steel pipes and boxes should be commensurate with their outer dimensions. For greater clarity, the corresponding ratios are summarized in special tables.

Round air ducts

Most of the characteristics of the duct depend on the shape of the section, since it sets the norms for the speed of air movement in the room and inside the ducts. This parameter determines the efficiency of the entire exhaust system (natural or forced) as a whole. If you evaluate the air ducts from this position, the circular cross section is the most preferable. When it is used, vortices are practically not formed inside the pipes, the forces of friction against the inner surfaces of the walls are minimal.

All other things being equal, the round shape of the duct is suitable for obtaining the maximum efficiency of various types of hoods.

Rectangular ducts

Sanitary standards and other permits are allowed to install rectangular pipes (boxes) made of stainless steel or black steel. The air moves along them not as well as in the version with a circular cross-section, but in this case, they proceed from the design features of the premises - it is not always convenient to mount pipes. This explains the frequent use of rectangular structures, which are significantly inferior in efficiency to the first.

Disadvantages:

- Individual parts of the boxes are mated with flanges with seals, through which air leaks often occur.

- The air mass flows in the internal spaces are unevenly distributed, creating turbulent zones.

- The noise rises.

When designing systems using large-sized boxes, the negative effects only increase, significantly reducing the efficiency of ventilation. In addition, additional funds have to be invested to pay for the electricity spent to compensate for the considered shortcomings.