Any living or working space requires fresh air. There are sanitary and hygienic standards according to which air masses must be renewed every two hours. The lack of sufficient oxygen saturation is especially noticeable when performing physical work in production. To ensure the supply of fresh air to the work shop, as well as to clean the room from dust and fumes, the installation of powerful professional ventilation systems is required.

Features of industrial ventilation

The workshop, site and other production facilities require a special air conditioning system. It will be different from a household or office one. This is due to the peculiarities of the room itself. In production, dust and dirt often form in the process of work, harmful fumes in chemical plants, and excessive moisture appears. A professional ventilation system can cope with these problems. It represents a whole range of engineering solutions aimed at uninterrupted purification of air masses and oxygen flow without disrupting the technological process.

The main tasks that industrial ventilation performs:

- Support for air exchange at a given frequency. According to sanitary standards, the air must be renewed every two hours. This figure may vary depending on the type of production.

- Ensuring the advancement of air flows.

- Removal of dust, odors, gases, excess heat from the room.

- Creation of a microclimate suitable for work.

The engineering complex of industrial ventilation can be divided into two types:

- Local. Its main task is the local elimination of harmful substances in the place of their formation. The source of harmful vapors is closed on all sides with shields in the form of a cap, so that substances do not enter the air.

- General exchange. Responsible for cleaning air masses in all production areas.

According to the principle of operation, production systems can be divided into the following types:

- Supply ventilation. Provides free flow of fresh air into the room. Duct fans are widely used in such systems.

- Exhaust type. Contaminated air currents are removed and new air enters in a disorganized manner through doors, windows, crevices and other openings. Exhaust ventilation of industrial premises is used in workshops where work is carried out related to harmful substances, excessive moisture or heat, as well as where many people work.

- Supply and exhaust type. Combines both previous types.

If supply ventilation is selected, there is a classification by installation:

- Monoblock. The devices are simple to operate and maintain, but they are expensive. Air ducts and power are connected to the unit.

- Typesetting. Devices requiring special skills for installing ventilation in production. They are distinguished by a low price.

It is better to install a supply and exhaust system. But before its installation, calculations are required so that air flows do not enter adjacent rooms and are not removed from there.

Air distribution methods

In any room, air can be circulated by stirring or displacement. In the first case, diffusers are placed on the ceiling and wall platforms, through which fresh air flows enter. Inside the building, they are mixed with waste and then removed through a diffusion valve.

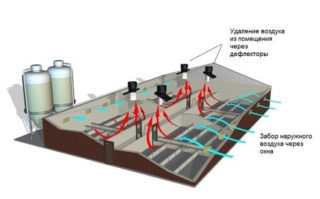

For displacement, low speed air distributors are installed in the lower part of the room, thanks to which the forced supply of fresh air is carried out. New cooled air flows are distributed along the lower part, warm air flows upward and is removed naturally through the roof ventilation.

Organization of natural ventilation in production

Natural ventilation in the room occurs due to the emerging difference in the pressure of the air currents, their temperature and direction of movement. An example of this type is airing a room by opening windows and doors. This method is also called disorganized, since natural physical phenomena occur that a person cannot control.

The positive qualities of natural air exchange include the low cost of the organization. Installation of filters, professional fans, diffusers and other technical equipment is not required. But due to the impossibility of control, such a system cannot be the only one in production. Also, the volume of renewal of air masses is insufficient to maintain an optimal microclimate.

Mechanical ventilation

Mechanical or artificial ventilation is created using fans. Ventilation systems for industrial premises of this type require energy resources and financial costs. The main advantages include:

- Creation of air intake from the required space of the enterprise. In a room that needs enhanced air purification, more powerful equipment can be installed.

- Adjustability.

- Creation of air supply directly to the workplace, exhaust with filtration.

The choice of the right industrial mechanical system depends on the volume of production, purpose and its capabilities.

Calculation of supply and exhaust ventilation

The first step in designing a system is to identify the source of the hazardous substances. The next step is to calculate how much air must be removed for the safe work of employees. In ideal conditions, the calculation is made according to the formula L = N x mwhere:

- L - the amount of air used;

- N - the number of employees;

- M - consumed air per person per hour.

In the case of a ventilated room, M is equal to 30 cubic meters / hour, and in an unventilated room, at least 60 cubic meters / hour.

If various substances are used, their permissible concentration must be calculated. In this case, the air flow is calculated by the formula L = Mv / (ypom - yp)... Here L - the required amount of fresh air; MV - harmful substances entering the room mg / h;yom - specific contamination of the entire area, mg / m3; yп - the amount of substance in the air flow, mg / m3.

Welding Ventilation

During welding, masses of impurities are released into the air, which are harmful to human health. Constant removal of nitrogen oxide, carbon, fluorine and other chemical compounds through ventilation systems is required. The type of ventilation depends on the volume of production, the capacity of the equipment and the time of its operation.

If the production is small and the capacity of the welding shop is small, local ventilation can be organized. It is sufficient for air purification in confined spaces.

In the case of technological processes throughout the entire area of the workshop, local ventilation will not be effective.In this case, it is advisable to use a general exchange air duct. This can be an exhaust hood in the upper and lower parts, as well as the creation of forced flows and heating the room.

Basic requirements for the ventilation system in production

To create an optimal air exchange scheme at production facilities, the norms of SNiP "Ventilation of special and industrial buildings" are used. They contain the following provisions:

- The installation of the system is carried out in any production area, despite its pollution and the number of employees. This is required for safety reasons in the event of an emergency.

- The system must not become a source of pollution.

- The noise should not go beyond the norms established by SanPiN.

- In the case of work with harmful substances and high air pollution, it is necessary to increase the number of pulling devices. In a clean room, a greater flow of air is required. In other cases, a balance must be observed.

- One person has at least 30 cubic meters / hour of fresh air. More accurate calculations take into account room humidity, excess heat, pollution, heating in the cold season.

If all standards are met, you can install any system that will provide the required efficiency of removing polluted air and fresh air.