High-quality air exchange is a prerequisite for creating and maintaining a healthy and comfortable microclimate in the premises. In many ways, the quality of air circulation is determined by ventilation valves, which should be installed in the supply and exhaust openings. This topic is especially relevant for apartments and houses where plastic windows and steel doors are installed, which make the premises airtight and create the effect of a thermos in them.

The need to install ventilation valves

Often, residents of multi-storey buildings have to deal with an unpleasant odor that penetrates into their apartments from the holes in the ventilation shafts. This phenomenon can be triggered by weather conditions or clogged communications. Regardless of the reason, it can be repeated several times, causing a lot of inconvenience to people. This is not the only problem.

The installation of an air ventilation valve is carried out, since in rooms where there is no normal ventilation, the following problems may arise:

- Rollover traction. Air from the street is drawn into the mine and, collecting waste from the sewer, kitchen, rooms, spreads over all floors of the building. In the apartments, extremely unpleasant odors are formed, which make staying in the house unbearable.

- Blowing out the atmosphere from the exhaust vent. In winter, this leads to hypothermia of the rooms, the ingress of snow. In summer it brings in moisture, leaves and insects.

- Penetration of combustion products of fuel boilers into housing. Many property owners do not run chimneys outside, but into shared shafts, saving money on drilling outside walls. Gas can enter the apartment and poison its residents.

- Violation of natural air exchange. Stagnation leads not only to high humidity and damage to interior items. Lack of oxygen provokes a headache, and humidity causes deterioration of clothes, destruction of structures of wooden buildings.

The air valve for ventilation is an important part that, with a small investment, can bring huge potential profits in all areas of human life.

Design and principle of operation

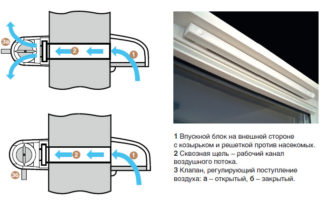

The ventilation valve is a fairly simple device that works in stand-alone mode. The principle of operation is to open it under the pressure of air moving under the influence of traction force. When it disappears, the valve closes, preventing contaminated masses from entering the room from outside the building or from the exhaust shaft.

A standard supply and exhaust valve has the following design:

- Plastic or metal duct. The pipe can be round or square and in various sizes. The length of the channel is up to 100 cm, based on the installation in a thick brick wall.

- A plate that completely covers the duct. This is the working part of the product. It should open as freely as possible, and when closed, completely block the opening. The damper can be one-piece and have the shape of a circle, square, or made in the form of a butterfly that turns in both directions.

- Filter. It is used to delay street debris, prevent the formation of contaminants inside the channel, on the actuator and damper, as well as hoods when installing forced ventilation.

- Fastening mechanism. It represents the axis on which the petals or flap are mounted. Hinges are another option. The valve is freely suspended from them or the products are equipped with a weak spring. Some models are equipped with an electric drive to open and close the channel with low natural draft.

There are exhaust valve options that have a fan and an external grille that is fixed to an external wall. In such cases, the valve is placed inside the channel. When installation is carried out in areas with cold climates, the inlet valve is inserted into the heated wall.

Advantages and disadvantages

As with all engineering designs, exhaust systems using valves have their pros and cons.

Advantages:

- There is no need to frequently open windows to ventilate the premises. Less wear and tear on fittings, less dust and noise in the room, and less risk of objects falling from the window sill.

- The circulation is carried out continuously, without human intervention. The air does not stagnate, there is no high humidity. The device can work in any weather, opening and closing on its own.

- The performance of ventilation devices is much higher than that of air inlets in plastic frames.

- Compact dimensions. The air inlet valve can be easily hidden behind a radiator or curtain in the living room without spoiling its interior.

- The plastic valve can be adjusted to increase or decrease the volume of air passing through it.

Disadvantages of the product:

- The need to drill a through hole in the wall in order to build the system and insulate it in order to prevent the formation of condensation and ice.

- Decrease in indoor temperature in severe frost.

- Complexity of service. The valve must be regularly cleaned of dust and dirt and can be difficult to access.

When choosing a model of room devices, a number of factors must be taken into account in order to ensure high-quality and constant air circulation.

Rules for choosing ventilation valves

When deciding to purchase a ventilation valve, you should pay attention to the following criteria:

- sufficient performance;

- sound volume when the dampers are closed;

- strength;

- resistance to moisture, ultraviolet light and active reagents;

- durability and wear resistance;

- control method (manual, mechanical, electrical);

- appearance (the apartment valve must be in harmony with the interior).

It is worth paying attention to the material of manufacture. Metal products are better in all respects, but more expensive. However, you should not be guided by the price, since the system is being made for decades.

Installation technology

The following options for installing a valve for taking outside air are optimal:

- under the ceiling on the outside wall;

- behind a heating radiator;

- under the windowsill;

- in the blind panel of the balcony door (sandwich);

- over the window opening.

It is not recommended to insert the device from the side of a street with heavy traffic - this way it will quickly become dirty and let harmful substances into the room.

To install the air intake valve, you will need the following tools:

- perforator, diamond-coated crown;

- ruff;

- polyurethane foam, plaster;

- knife;

- screwdriver;

- roulette;

- marker.

If the duct needs to be insulated, a heating cable or heating mat can be used for this.

Installation is carried out in the following sequence:

- Preparation of the base. Markings for drilling are applied from the inside, and hinged panels are dismantled from the outside. Attach a plastic bag or dust bucket to the wall.

- Making a hole. It is necessary to take short breaks to cool the instrument. At the end of the process, clean the canal with a brush, wet cloth or industrial vacuum cleaner.

- Installation of thermal insulation.Its inner diameter should be 5-10 mm larger than the guide tube.

- Channel installation. It should be fixed with polyurethane foam or sealant.

- Valve installation. If it is provided by the project, the fan is installed, its connection is carried out and its performance is checked.

In conclusion, chips are sealed, internal and external grilles are attached.

The operation of the supply and exhaust system of the valve consists in its periodic cleaning. In conditions of severe pollution, this is done once a quarter, in a clean area - every six months. Cleaning is done with a brush and a damp sponge. Grilles, ducts, filters, dampers, fan blades must be processed. Metal parts should be cleaned of rust and lubricated.

Do-it-yourself supply valve

The simplest solution for making a check valve is to use a 100 mm sewer pipe, a ventilation grill, a piece of plastic and small loops. The pipe is inserted into the wall, the plastic is attached to its wall with hinges. Then a sealant is applied to the pipe, and a soapy solution or machine oil is applied to the plate. Both parts are combined until they solidify - an O-ring is formed, which will extinguish the pops. It remains to close the valve with a ventilation grill, using a piece of plastic pipe to provide the necessary space for opening.

Top manufacturers

According to consumer reviews and based on an analysis of the sales market, the products of the following manufacturers have proven themselves best:

- Flakt Woods;

- Vents;

- Aereco;

- Helios;

- Domvent;

- VELCO;

- Era.

The goods should be bought in branded outlets after checking the availability of a quality certificate.