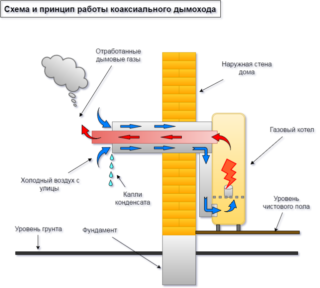

A coaxial chimney is used to organize the removal of combustion products and the supply of fresh air in one pipe. The design of the channel includes two contours of different sections, located one in the other, while the distance between the walls will be the same along the entire length. Complete tightness and gas tightness of the heating system is achieved when using such a discharge channel.

Definition of a coaxial chimney

The device works on the principle of combining the functions of a chimney and a supply ventilation system in one product. Combining the channels increases the boiler performance and efficiency. The temperature in the chimney is leveled, the appearance of condensate drops is excluded, due to the mutual redistribution of heat between the internal and external flows.

The coaxial type is suitable for gas boilers with a closed system and natural or organized forced draft force. A small fan is installed inside the pipe. The design of the line includes a condensate collector and inspection holes for cleaning.

Heat losses are minimized because cold air is supplied in an outer tube that heats up from an inner hot gas duct. Warm air enters the room and reduces heat loss. There will be clean air in the boiler room, since the coaxial channel simultaneously acts as supply ventilation.

The pipe can be installed vertically or horizontally, installed in a wall form under the ceiling, led out through the roof structure, walls or window. Pipe dimensions and power are selected in accordance with the calculation. The fuel burns out completely and less hazardous substances enter the atmosphere, gas is saved. Combustion products are discharged through the inner channel, while the outer side maintains an average temperature, therefore, the risk of fire is reduced.

The principle of operation of the device

Features of the functioning of a coaxial chimney:

- fresh air is supplied from the outside along the outer shell to support combustion;

- the inner passage is used to remove smoke outside the room.

The main line of coaxial pipes is made up of separate standard modules, as a result, the chimney can be of different lengths or heights. With the help of straight pipe sections, adapters, corners, tees, a pipeline of various configurations is made, which takes into account the architectural features of the structure.

Unified elements are selected for pipes of various cross-sections in accordance with standards and technical requirements. Air in heating systems with a single chimney is taken from the boiler room, so the room becomes stuffy and breathing is difficult.Another option for oxygen supply involves taking from the street, but requires connecting an additional air duct pipe.

Varieties of coaxial chimney

The pipe material is aluminum, stainless steel, plastic or combinations are used. A plastic chimney is connected to condensing gas units, but its disadvantage is a short service life. A heat-resistant polymer is used, which does not collapse when the smoke is heated up to + 205 ° C, so the plastic can only be installed on boilers with a temperature regulator for exhaust gases. Plastic lines are lightweight, do not require a frame. Installation of inexpensive pipes is quick and easy.

According to the standards, stainless steel is the most resistant material, since it resists the acids contained in condensate and can withstand gases up to + 550 ° C. Manufacturers have developed several design types of internally separated pipelines. Products are used for a long time without loss of quality, are used in mansions, apartment buildings and industrial buildings. Coaxial stainless pipes are produced in a heat-insulated and simple version.

Heat-insulated products are used for a two-channel chimney and serve for more than three decades. The design uses a combination of materials such as polymer and high alloy steel, stainless steel and aluminum.

Outdoor and indoor systems

The chimney can run inside the building or be located outside the wall. Structures from the outside worsen the appearance of the facade, therefore they are placed in the space of the room. Compliance with the installation rules, which are spelled out in SNiP-91, paragraphs 3.70 and 3.71, is checked.

Before installation, the internal flue exhaust systems are checked for compliance with the dimensions of the connecting outlet of the boiler and the pipe. The diameter of the outer hole in the enclosing structure or roof is made according to the size of the pipe section. The internal chimney is installed from the stove or fireplace, fastened to the walls with clamps, crimped with bolts. Decorative overlays, wooden or plastic, are placed on top of the pipes. They do not pose a fire hazard, since the outer layer is cooled by passing air from the street.

The installation of an external exhaust flue also starts from the boiler. When passing through the wall, the correct insulation of the hole is made. For a set of the required length, the coaxial chimney can be lengthened and built up, but this cannot be done in the thickness of the wall. The outer parts are fastened to the fence with clamps. The assembly is carried out until the required height is reached, a deflector is placed at the end of the pipe to increase traction.

Insulated and non-insulated systems

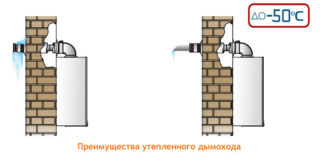

Cold insulated stainless coaxial pipes are ideal for outdoor flue gas venting. The aerodynamic characteristics of the channel are improved thanks to the insulating layer. Boilers with forced or free draft are connected, but the first option works more efficiently.

Insulation from cold is needed because the external air supply chamber freezes at sub-zero temperatures, which reduces the volume of supplied oxygen. Gas burns unevenly, the boiler efficiency deteriorates. The difference between the temperature of the inner pipe and the outer compartment increases, which leads to the formation of condensate and accelerates the destruction of the coaxial chimney for a gas boiler.

Materials used:

- mineral wool;

- basalt masses;

- glass wool;

- polyurethane foam, polystyrene foam.

The insulated version of the pipe is a structure containing three pipes of different cross-sections, nested inside. One cavity (outer) is filled with a cold insulating material.

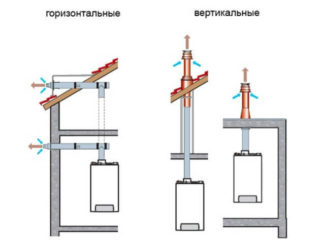

Horizontal and vertical output

Coaxial chimneys were originally planned as horizontal ducts, but this arrangement is not always convenient in the house. The number of turns of the chimney should not be more than three. A 90 ° turn denotes an extension of the pipeline by 1 meter, a 45 ° bend angle - by 0.5 meters, the total length of the pipeline should not be more than three meters.

To install a horizontal pipe can cause problems:

- small boiler room;

- a large number of windows (for the front part);

- the presence of foreign structures in the gap between the boiler and the wall with a hole;

- inability to provide a standard slope of 3 ° for condensate drainage.

The smoke outlet is organized vertically and in a mixed version. Vertical withdrawal is used if the roof structure allows it. This option requires high-quality insulation of the passage. For fastening, brackets are used to provide a distance from the roofing elements, since attention is paid to preventing fires. A protective cover covers the connection point.

Collective and individual designs

The division of chimneys is introduced depending on the scheme and the number of users served. The collective chimney is a shaft system to which separate pipelines from each heating unit are connected. Individual branches are thermally insulated, which increases their traction characteristics.

In multi-storey buildings, separate passages to the common vertical outlet are provided during the construction phase of the building or added during the reconstruction process. External wiring is used less often, while the gas units of an apartment building are connected, and the main vertical channel is located on the street side.

The individual pipes are connected using a tee adapter with gaskets, inside of which there should be no obstacles or protrusions. Extend the length with the elements of the adapters, ensuring the tightness of the joint with the help of tightening clamps.

Individual chimneys are used for domestic purposes, serve one heating boiler and do not have branches. To collect condensate drops in the line, collectors are provided in the form of standard pipeline inserts.

Advantages and disadvantages

Benefits of using coaxial pipes:

- the isolation of the system excludes the ingress of carbon monoxide into the house;

- reduced fire hazard excludes fires;

- the versatility of installation allows you to install pipes horizontally and vertically, use in an apartment or a private house;

- saving space by combining two functions in one channel;

- installation does not require professional skills or special tools;

- reduction of air emissions due to increased productivity and complete combustion of fuel.

The disadvantage is that the coaxial chimney serves gas units with a closed firebox, and is not used for other boilers. External pipes are installed three-chamber, with factory thermal insulation, and if you carry out additional insulation of a two-chamber pipe, you need to finish the element on the facade in accordance with the exterior of the building.

Features of the choice of size

The technical passport of the heating unit contains information about the diameter of the connected pipe and the length of the coaxial channel. Increasing the parameters leads to a decrease in performance. The diameter is written in the article after the letter designation and contains 4 numbers. The first ones speak of the internal section of the pipe, and the last two indicate the external size of the chimney.

The length of the line cannot be more than three meters, according to the installation procedure, but individual manufacturers change this characteristic based on the technical indicators of their products.

Pay attention to the diameter of the unit outlet pipe, which must match the pipe size. Do not install a flue pipe with a diameter smaller than the same size of the pipe. In the technical documentation, a selection table is attached, which takes into account the nuances of choosing the diameter, length, slope and number of channel turns.

Installation rules

Installation of a chimney from coaxial pipes is not difficult. The axis of the forced draft pipe can be moved relative to the unit to the right or to the left.

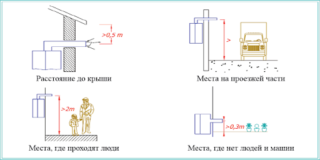

Installation features:

- from the boiler to the outlet through the wall must be at least 0.5 m;

- height above the horizontal pipe inside the room - from 0.2 m;

- the outer outlet of the pipe is more than 0.3 m;

- the height of the horizontal outer pipe from the ground - 2 - 2.5 m;

- distance from the head of the vertical pipe to the nearest wall - 0.6 - 1.5 m;

- adjacent windows or ventilation openings - no closer than 0.6 m from the chimney outlet.

The chimney is attached to the unit by means of a corner piece (elbow), tightening clamps are used. An inlet is marked on the wall, the width of which exceeds the diameter of the pipeline by 5-10 cm.

Do not use adhesive tape, scotch tape and sealants when connecting the line elements. Special gaskets or rubber are used. The passageway is insulated from the flow of cold with a non-combustible insulation. Vertical pipes are recruited to the required height, which is always higher than the ridge of the roof and openings of the neighboring house. After installation, the operation of the system is checked.