To heat a small technical building, a stove is often used, but before installing it, you need to select and equip a combustion product outlet structure. Most often, a chimney is installed in the garage through the wall.

Chimney device

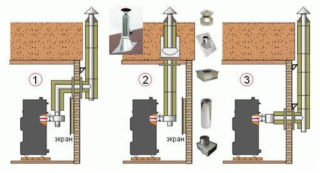

The design scheme provides for the use of several structural elements: pipes, bends, deflector. Such a withdrawal of combustion products is easier, but it is not always possible to use it. The pipe comes out at the level of the stove outlet or at a height of 20-25 cm from the ceiling.

The second option is preferable - by heating up from the smoke, the pipe turns into a kind of heat exchanger, which additionally heats the space. The first type of design provides for the output of the element outward at the level of the stove. Its vertical part is fixed on the street on the wall. This option is the safest in terms of fire.

Materials and design features

To make a chimney for a potbelly stove in a garage with your own hands, you need the following materials:

- pipes made of metal with thick walls (the length and diameter of the product is determined at the design stage);

- tee equipped with a plug;

- a cap for closing the chimney from debris or precipitation;

- adapters for connecting the stove to the outlet pipe;

- heat-resistant sealant, outside pipe insulation material, asbestos cord.

The garage is additionally equipped with a ventilation system. In order for the chimney to be resistant to ignition, the following design features are observed:

- The stainless steel chimney is assembled from component parts. In this case, it is easier to clean and easier to dismantle in case of breakage.

- All joints and seams are carefully sealed. For this, an asbestos cord is used.

- If the stove will be used frequently and for several hours a day, it is better to divide the structure into 2 parts: a heat exchanger and a flue duct.

To avoid the smoke of the garage, a tight lock is installed in the pipe. The valve system will allow you to independently regulate the strength of the flame.

Pipe selection recommendations

The correct chimney for a potbelly stove in the garage must effectively remove the combustion products. The brick option in this room is not welcome. This design is heavy and bulky. For its arrangement, skill is needed, as well as strengthening of the foundation.

Asbestos pipes are difficult to install. They do not withstand high temperatures and crack at 300 degrees. Products of this type are heavy. They absorb condensation, making them difficult to clean.

The best material for making a chimney is stainless steel or corrugation. Corrugated elements are suitable for creating a structure inside the garage. It can be easily routed to a tee against a wall or roof. Stainless steel is a versatile product that is laid not only inside the garage, but also on the street.

It is better to use alloy steel. It can withstand ultra-high temperatures and can last up to 10 years.

Instructions for the construction of a chimney in the garage through the wall

The complexity of the construction of a chimney through the wall depends on the characteristics of the building material from which the garage is made, the placement of the stove. You need to prepare for work. Measurements of the diameter and total length of the pipe should be made. The first parameter must be at least 2 times greater than the volume of the combustion chamber. Otherwise, the thrust will be insufficient.

It is necessary to determine the number of parts for the connection. To prevent condensation from impairing the smoke output, a method is provided for its removal. For this purpose, a tee is installed. The chimney pipe should rise 1.5 m above the slate and roof ridge.

The orifice for the nozzle is prepared in advance. Here it is necessary to ensure the fire safety of building materials in contact with the pipe. For this, heat-resistant materials are used.

Chimney assembly

To arrange the hood, all the parts must be laid out in a given sequence. This will help to fold the structure correctly. If a sheet of stainless steel is used for work, scissors, a pipe bender, a hammer are required.

Installation of all components

The wall behind the chimney must be lined with heat-resistant material. If the pipe will be led out through a wooden wall, it is placed in a heat-resistant box, which is filled with glass wool or fine expanded clay.

The pass-through knot is fixed not only from the outside, but also from the inside. Further, the pipe of the potbelly stove is connected to the lower part of the chimney. For this, a heat-resistant seal and a special clamp are used. Since the outlet is in the wall, the next element to be installed is the elbow with the desired angle.

After the branch pipe is brought out into the street, an element is put on it, which sets the chimney in a vertical position. The outer part is insulated, a protective mushroom is put on the pipe itself. Doors are installed at the folds for inspection and cleaning of the structure.

Since you can make chimneys for potbelly stoves in garages with your own hands, the design is not expensive. Before its final fixation, the heating system is checked. During the melting of the potbelly stove, the draft in the chimney should be assessed.

Maintenance and care features

The structure is checked annually for mechanical damage. Cleaning the garage chimney is required every six months. For this purpose, brushes or chemicals that dissolve soot are used. The mechanical option is more effective, but unacceptable for stainless steel. In this case, the use of a hook is permitted.

Before the start of the heating season, the tightness of all chimney connections is checked. To prevent the appearance of soot on the inner walls of the pipe, you can use aspen firewood. The special chemicals used to treat the logs are capable of dissolving the soot. This method is safe for a metal pipe.

If the product shows through damage, it must be replaced. They will reduce draft and smoke into the room.

If you correctly build and operate chimneys from a profile pipe for stoves, the heating structure will fully fulfill its functions. It is necessary to follow the rules for operating the structure.