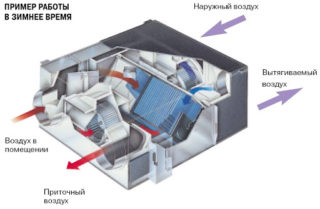

A good ventilation system creates an inflow of fresh air masses from the street and the discharge of spent air into the external environment. In the cold season, a lot of heat is lost; low temperature air gets into the room from the street. In order not to waste fuel on heating the street, homeowners often consider connecting a recuperation device. Ready-made devices have a high price, but you can make an effective recuperator for a private house with your own hands.

What is a recuperator

Devices transfer heat from already heated air masses to cold ones coming from the external environment.

Heat exchangers for a recuperator are of several types. The most common are plate and tube recuperators.

The economic effect of using the device is determined by investments in its installation and maintenance, as well as the planned duration of operation.

Recuperator types

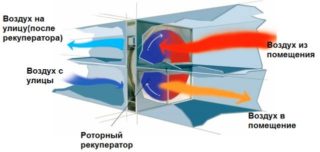

Devices differ in design, mechanism of operation, nature of air movement.

By the type of movement of the coolant

Air flows are directed differently for different devices. In direct-flow models, the supply and exhaust flows run in the same direction parallel to each other. In countercurrent devices, their vectors are opposite to each other. For cross-flow devices, they are directed at right angles.

By design and principle of operation of the heat exchanger

One of the most common types of devices is rotary. The device of such a recuperator includes a sealed body and a drum placed inside, moving thanks to an electric motor. When the rotor spins, it enters the area of warm air masses, then into the cold area. During the process, the drum is heated and cooled. Such a scheme of the recuperator operation ensures the transfer of heat to the air coming from the external environment.

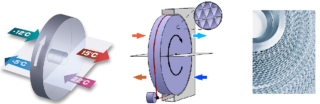

In a plate device, the heat exchange cassette consists of a large number of flat elements of a rectangular, square or other shape. There is a distance of several millimeters between adjacent components. When heated air passes through the plate structure, heat is transferred to the elements, which then give it to the cold stream. Heat transfer is realized due to the parallel heating and cooling of the plates.

If you want to assemble a recuperator with your own hands, it is better to give preference to the plate version due to its simplicity.

Advantages and disadvantages

Plate models often attract attention due to their low price, compactness, simple structure without moving elements. But in cold weather, under the influence of condensation, the plates are subject to freezing. This forces us to look for ways to combat this phenomenon.The most effective of these is to install a cellulose cassette to absorb excess liquid. In this case, water from the condensate is directed into the dwelling and humidifies the air. Such a device works in all weather conditions.

Recuperator selection rules

When considering a model for purchase, it is necessary to assess how much its characteristics correspond to the data of the room in which the device is planned to be installed (height, area, required exchange rate). To calculate these parameters, it is advisable to contact a professional, since this procedure requires a good knowledge of building codes and laws of movement of air flows, and it will be expensive to replace the device in case of an error in the calculations.

It is important to determine how much air in cubic meters should flow into the room in 1 hour. According to sanitary standards, the minimum value is 30 m2 per person. In reality, this indicator, associated with the performance of the device, will be higher due to a large number of costs: duct resistance, the size of the room served, etc.

Also, when choosing, attention is drawn to the sensitivity and reliability of the automation unit. Many modern devices are equipped with one or another additional functions: regulation of the power of ventilation devices, air flow pressure (the amount of carbon dioxide in the hood is estimated), etc.

The degree of noise generation of the device should be assessed.

Some units are wall-hung, while others are floor-mounted. There are horizontally located models. A suitable version is selected depending on the installation location and system parameters.

Making a recuperator with your own hands

An air recuperator for a private house can be made by hand from different materials. Sometimes enthusiasts assemble devices using sewer pipes as a basis. You can make a foil recuperator. Plate devices are distinguished by simplicity of execution and at the same time efficiency. Blanks for flat elements can be made of aluminum or polycarbonate.

When making a recuperator for an apartment with your own hands using sheet aluminum, it is preferable to take thin raw materials - in this case, heat exchange is more efficient. In addition to metal sheets, a homemade recuperator requires the preparation of materials and tools:

- mineral wool 2-3 cm;

- wood slats 2 mm thick and 10 - wide;

- plywood sheets for the body;

- hermetic and adhesive compounds;

- fan;

- 2 pairs of flange elements (for tube section);

- hardware.

The height is adjusted in accordance with the total number of plates and their thickness when fastened to the rack elements. The diagonal parameter is made identical to the width of the heat exchange element.

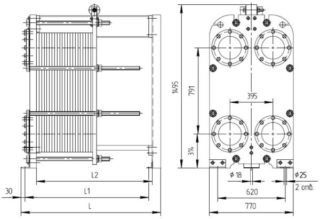

Schemes and drawings

DIY drawings for a recuperator include a blank for the plate. The side of the square is usually made 0.2-0.3 m. The total number of plates should be at least 80. For them, slats are also prepared according to the dimensions of the sides of the square. They are covered with linseed oil and are connected with glue to the inside of each plate. Only one metal square is left without the rail.

The components are connected to each other. It is advisable to alternate horizontally and vertically located plates, so that each is at right angles to the neighboring ones. This increases the efficiency of the device. A square without a frame is placed on top. The cracks must be filled with a sealing compound.

Flange fasteners are made and the structure is placed in a prefabricated housing. The heat exchange element should abut the corners against the side walls, like a rhombus. Holes are made in the device for flange parts, and in the lower part, a hole is made to drain condensed moisture through a hose. Then the homemade air recuperator is covered with mineral wool.Connect the device.

Power calculation

The performance of the device in cubic meters per second can be calculated if the volume of air mass inflow per person required by the standards is known. If we denote the first value by the Latin letter Q, and the second - L, the calculation formula will take the form:Q = L * 0.355 * (tlump - tst)where:

tlump - required room temperature;

tst - the value of the indicator on the street.

To find the efficiency of a device, you need to know 3 temperature indicators: t1 - on the street, t2 - parameter of the air entering the dwelling after passing through the device, t3 - home air before recuperation. Then the efficiency will be equal to (t2 - t1) / (t3 - t1).

The use of recuperative devices helps to minimize the flow of warm air from the room to the outside during the cold season. Self-manufacturing of the device will cost less than buying a ready-made one, but modern industrial recuperators are equipped with a large number of additional options.