Safe and uninterrupted operation of gas boilers is achieved when all building and fire safety standards are met. The boiler flue pipe plays an important role in ensuring the normal functioning of heating. For self-construction or control of the work of builders, you need to know all the rules and requirements for gas outlets.

- Types of boilers and flue ducts

- Open chamber boilers

- Features of equipment with a closed chamber

- Guidelines for the arrangement

- Requirements for the installation and outlet of the chimney

- Allowed Materials

- Where to bring the chimney

- External parts construction

- Geometrical dimensions and configuration

- Output of coaxial channels

- Thermal insulation

- Features of apartment heating systems

- Selection and arrangement errors

Types of boilers and flue ducts

The industry produces various models of gas heating boilers, but all types are built in two possible schemes: with an open or closed chamber for gas combustion.

It is better to decide which boiler to buy at the design stage of the house. The chosen scheme determines how and where to build a boiler house, as well as how the combustion products will be discharged.

The project must be coordinated with the gas supplying organization - if the construction technology is violated, the use of unacceptable materials, the gas equipment cannot be put into operation, and alteration of the gas disposal system may require significant financial costs.

Open chamber boilers

Oxygen for fuel combustion is supplied from the surrounding space. This feature imposes additional requirements on the organization of room ventilation.

Installation of equipment is carried out only in a separate room. To ensure functioning, two channels are built for supplying air and removing products from the burnt gas.

Among the advantages is the relative simplicity of the design without additional fans, which means without "extra" mechanical parts that are most susceptible to wear and tear. The disadvantages should be considered a lower efficiency and the need to build a vertical chimney at a level above the roof ridge.

Features of equipment with a closed chamber

Air is forced into gas boilers with a closed chamber. The chamber does not communicate with the room air, and the exhaust gases are removed by the blower.

Boilers with a closed chamber are economical, do not require the arrangement of vertical channels, one coaxial pipe is used. The combustion products are discharged through the inner insert, and outside clean air enters through the cavity between the pipe walls.

It is not necessary to build vertical structures to remove gases, which reduces the cost of the estimate. On the other hand, this type of boilers and pipes requires more frequent maintenance. Turbines periodically fail, which entails additional operating costs.

Turbines generate noise, so it is better to install the boiler in a separate room.

Guidelines for the arrangement

Gas equipment is not difficult to operate, but the use implies compliance with a large number of rules at the design, construction and daily operation stages.

The rules for arranging the boiler chimney are determined:

- SP (Code of Rules) 60.13330 - 2016

- SP 402.1325800.2018

- SP 7.13130-13

- SP 282.1325800.2016.

Each of the documents refers to many SNiPs, GOSTs, SP.

The most complete information on how to properly make a chimney for a boiler with your own hands in a private house is contained in SP 402.1325800.2018, in Appendix D - "Smoke and ventilation ducts".

Requirements for the installation and outlet of the chimney

The requirements can be divided into several parts:

- materials permitted for construction;

- geometric dimensions and configuration;

- options for connecting to common building channels:

- thermal insulation.

Allowed Materials

Chimneys for gas boilers are made of materials that do not support combustion, the roughness of the inner surfaces of which is not more than 1 mm. The material must ensure tightness class B, and the joints must exclude air leaks.

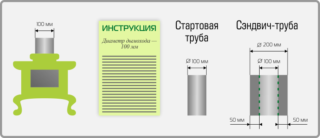

The material for the channels can be: ordinary ceramic or clay bricks, heat-resistant concrete, ceramic or steel insulated sandwich chimneys.

The outer surface of brick channels is made of frost-resistant bricks. The use of asbestos-cement pipes without an outer brick or concrete shell is not provided.

It is allowed to use industrial chimneys that come with gas-fired boilers - the products are subject to mandatory certification.

It is forbidden to make chimneys from cinder concrete and other materials of a porous structure.

Where to bring the chimney

Channels in newly built houses are placed in the cavity of the inner walls or attached structures are made. In existing buildings, external walls or annex structures are used to accommodate pipes. The demand is due to improved energy savings - heated internal walls increase the temperature inside the premises, rather than heat the street.

It is forbidden to combine chimneys of gas equipment in built-in premises of residential buildings with ventilation ducts of apartments.

In newly built and reconstructed private houses, a separate canal is arranged for each boiler.

In houses of an old building, it is allowed to connect 2 units of gas-using equipment to the channel, if the inputs are separated by 0.75 m - if necessary, they arrange incisions of the required length. In houses commissioned, it is allowed to use already existing smoke channels made of non-combustible materials.

The rules allow connecting periodically connected devices to the boiler chimney, for example, water heaters. An important condition for this is that the boiler and heater must not work at the same time. The method is applicable when a double-circuit boiler is operating during the heating season (heating and preparation of hot water), and only the heater is operating in summer.

It is forbidden to combine chimneys of any gas equipment with chimneys of solid fuel stoves.

Wall ducts are allowed to be arranged in a mine shared with ventilation pipes. At the same time, along their entire length, they are separated by partitions with a wall thickness of at least 120 mm.

It is forbidden to lay chimney paths through bathrooms, toilets, living rooms.

External parts construction

Smoke ducts are led out above the roof. The mouths of the canals leading to the roof are protected from atmospheric precipitation. Caps made of galvanized steel or roofing iron are used, it is allowed to use cement mortar.

Geometrical dimensions and configuration

The section of the chimney pipe is chosen not less than the section of the boiler outlet pipe. This is in contrast to the chimneys of wood-burning stoves, where the minimum internal dimensions are strictly specified.

The total area of the gas outlet is selected based on the simultaneous operation if two boilers are connected to the channel. In this case, the cross-sections of the pipes are summed up.

There should be no ledges in the flue ducts, the pipes must run strictly vertically.It is permissible to make a slope at an angle of up to 30º for a deviated section with a length of no more than 1 m. The structure is necessary for bypassing the roof with an external channel or for connecting a boiler located not strictly under the chimney.

The total length of horizontal sections should not exceed 3 m for buildings under construction and 6 m for existing buildings.

It is allowed to arrange up to 3 turns for each chimney, the radius of rounding cannot be less than the diameter of the pipes used.

Below the place of connection of the chimney to the ducts, a "pocket" is provided with a hatch for cleaning. Access to the hatch must always remain free.

Gas-using equipment is connected to the channels with couplings and adapters made of roofing or galvanized iron. The minimum wall thickness of which is not less than 1 mm. It is allowed to install corrugated pipes or elements supplied with the gas boiler.

Output of coaxial channels

For boilers with a closed chamber, it is allowed to exit through the walls without the construction of vertical channels. In these cases, choose coaxial type chimneys. The maximum height of the house in these cases should not exceed 3 floors.

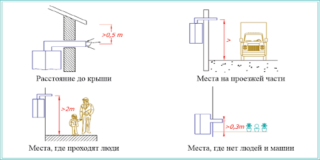

When removing the chimney to the facade of the building, ensure the minimum distances to other building structures:

- up to ground level 2m;

- 0.5 m in the horizontal plane to window and door openings;

- 1 m to the ventilation duct grilles;

- 1 m to the windows above the chimney;

- 0.5 m to the window opening and doors located below the pipe.

It is allowed to connect more than one closed-type combustion chamber boiler to each vertical chimney if the equipment includes a device for forced removal of combustion products.

The smallest permissible distances between the leads of coaxial channels are 1 m in the horizontal and 2 m in the vertical plane. The length of the horizontal part when leading through the wall should not exceed 3.0 m.

Thermal insulation

Chimneys from gas-using equipment passing through unheated rooms are thermally insulated.

Steel pipes running through the attic or along the wall of a building are protected with the thermal insulation necessary to prevent condensation from forming. In this case, the temperature on the surface layer of the insulation should not exceed 45 ° C.

Any freezing of the pipe in winter at the lowest temperatures is prohibited.

The distance from the chimney to the ceiling and walls made of non-combustible materials is maintained at least 5 cm, and to other materials at least 25 cm.The distance may be reduced to 10 cm if the thermal insulation meets the parameters specified by the manufacturer of the gas equipment - in general, the surface temperature building structures should not be higher than 45 ° C.

The thermal insulation material should protrude 15 m beyond the dimensions of the chimney.

Features of apartment heating systems

In recent years, a scheme has been gaining popularity in construction, when a separate boiler is installed in each apartment. This allows residents to independently choose the heating mode and temperature in the rooms.

The trend has caused the need to adopt a separate regulatory order of the Ministry of Construction - SP 282.1325800.2016. Section 7 of the document is devoted to the peculiarities of building systems.

The construction and design of chimneys in these cases does not differ from those described above. There is one important feature - the output of individual chimneys to the facade of multi-storey buildings is prohibited.

Selection and arrangement errors

When building a house, errors of the selected heating system and gas equipment occur at different stages:

- the design did not take into account the type of boiler - after the end of construction, it may be necessary to rebuild the entire ventilation system;

- unsuccessful form - an abundance of turns reduces traction, in some cases it provokes the movement of air from the pipe into the room;

- the possibility of cleaning is not provided, which can be hindered by sharp turns and the absence of technological holes;

- purchase of materials from different manufacturers - components for composite pipes may differ in geometric dimensions, which leads to air leaks or combustion products leaking into the room;

- non-observance of the height of the chimney on the roof, leading to reverse draft;

- the wrong choice of materials for the pipe;

- insufficient insulation.

Guiding documents permit the self-construction of chimneys for gas boilers. The gas supply organization will not accept improperly equipped chimneys into operation, and hidden defects can lead to accidents. It is necessary to study in detail the rules provided for by the governing documents; in case of doubts in their abilities, it is better to entrust construction to professionals.