The presence of an autonomous heating system requires the installation of a chimney through which the products of fuel processing are removed. Installing a chimney through the wall is considered the most practical option if it is carried out according to all the rules. For this purpose, it is necessary to know the design features and the principle of operation of the device, to study its main elements, to deal with the specifics and nuances of the connection.

Design features and principle of operation

Chimneys installed from the outside can be wall or root, in the second case they are placed on a separate foundation near the building. The pipe can be made of brick, single layer steel, sandwich pipe, asbestos cement or ordinary cement. The most difficult thing is to build a brick pipe, for this you need to have the skills of a bricklayer. Asbestos-cement options are quite fragile, it is difficult to select components for them, they also require additional insulation, and they can collapse under the influence of the condensate component. The best option is considered to be steel pipes that do not cause problems during installation and do not require the laying of insulation, while they are inexpensive.

The work of the chimney to the stove is based on the reaction of combustion substances, which, when heated, rush upward. The heated gases are able to expand, as a result of which their density decreases, then they pass into the elevated atmospheric layers. After raising the spent components, a rarefied layer is created inside the furnace, to which fresh air is added. For the constant supply of oxygen to the fuel, the thrust is responsible, which is influenced by the height of the chimney, the insulation of the channel and its cross-sectional area, the location of the head section in relation to the top of the roof, as well as the flow of the required amount of air.

The chimney is needed to remove waste products of combustion outside the house. This is the most important element, without which the normal operation of any oven is impossible.

The main elements of the chimney

A chimney of any kind consists of a vertical box, a gate valve, a head piece, cleaning hatches and a foundation, if necessary. The number of parts varies according to the material of the tube. The brick chimney includes a neck for connection to the furnace, a riser with sliding parts, a slope, a stainless steel liner, an otter, which is an extension for the pipe walls above the roof, and a metal cap. Asbestos-cement and steel options consist of pipes, a cap, adapters connected to the combustion chamber, insulation and outer casing, if required.

The most modern and durable are chimney elements made of sandwich pipes, consisting of three layers, or made of ceramics. They are assembled from ready-made factory parts, a large assortment of which makes it possible to quickly create a design with the desired parameters. The main parts of such pipes are straight or swivel parts, tees, elements for collecting condensate, adapters, deflectors and conical parts. Sandwich pipes are made from two layers of metal sheets, between which insulation is placed.Ceramic analogs are assembled from expanded clay concrete, a standard ceramic box and an insulating material.

Basic rules and steps for installing a chimney through a wall

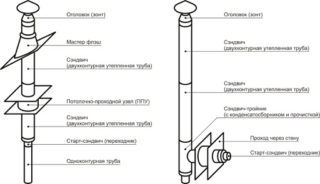

To install a standard chimney through a wall, basic safety rules and techniques must be followed. The installation scheme can be external, and the part is also placed through a wooden or frame wall.

On the outside wall

With this installation, the heating device influences the main parameters of the chimney. To regulate smoke fluctuations, you will need to create bends, the joints of which must maintain the desired angle. The branch elements are fastened to each other using a tungsten electrode, then dampers and special windows are mounted. If necessary, the barrier elements are placed in branch parts, pipes or transitions at the required distance so that they cannot come into contact with the tube wall. In addition, you will need to mount a stand for triple parts; for this purpose, a square tube is used, holding the part on the wall with dowels. Close attention must be paid to the distance between the wall and the chimney.

The output of such a chimney through the wall is carried out by tees made of stainless steel with thermal insulation. Due to them, the device is connected to the chimney, after which the tees will be used as outlet parts for condensate particles, cleaning and checking construction details. Branch pipes or inspection windows are placed at the bottom or on the side of the tees, which are straight-through, prefabricated or solid. For the complete installation of the chimney, brackets are used; in some cases, auxiliary fasteners may be needed. They are necessary to give the structural part of the load resistance.

The outside chimney always requires a layer of thermal insulation, the tube is placed in a protective cover, which is made of galvanized or stainless steel, as well as other materials with resistance to corrosion.

Through the frame wall

It is often required to install a stove in a house with a chimney through a frame wall. In order to obtain the desired result, the entire structure is treated with materials of an insulating type, for example, slag concrete, mineral wool or fiber insulation. The upper part of the tube is wrapped in aluminum foil and held in place with cable ties. Sometimes they immediately install sandwich chimneys with an insulation element, the installation of which is not difficult. They include two pipes with different diameters, a small one is embedded in a larger one, insulation is used as a filler for them.

Through a wooden wall

To install a fireplace chimney through the wall of a wooden building, you will need to strictly follow the rules regarding fire safety. The tube is lined with a strong fire-resistant frame, it can be bricks or asbestos. This procedure prevents the wood from drying out in areas adjacent to the chimney. Often, during the installation of the tube in wooden buildings, systems with two circuits are used.

Ideally, it is necessary to create a chimney layout where the horizontal connecting pipe would have a short length. The structure of such a chimney includes an element called a "gate", it helps to control the process of draft. As in the outgoing elements of the previous type, the neck is covered with a special cap. At the same time, the parts of the tube are fixed, maintaining a distance of one meter at a distance from each other, creating a chimney passage through the wall in a wooden house.

Specificity and nuances of connection

The chimney is considered the most complex part of the heating system, since the life and health of the owners of the building will depend on this element.During installation, it is necessary to fully comply with all the conditions of the standards, this will become a guarantee of safety and help to avoid possible problems.

Installation of a chimney from sandwich pipes

If you need to install a chimney with your own hands, for this purpose it is worth using practical, lightweight and easy-to-install sandwich pipes made from one-piece factory parts. The main disadvantage of such pipes is their inflated cost, but the owners can also save money by installing on their own. The absence of problems during installation allows you to install a safe chimney and connect it to any heating device. The main rules should be observed and ensured:

- optimal selection and calculation of the diameter of the pipes from the inside, including the calculation of the chimney height;

- observance of suitable distances from the surface of the pipes to walls and other structural elements;

- full insulation of the chimney duct;

- optimal sealing, correct and secure attachment to wall surfaces;

- mandatory installation of containers for collecting condensate;

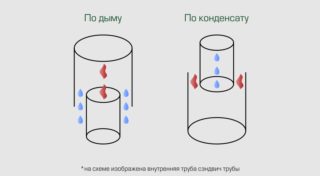

- assembly of condensate parts or the use of special modules that can be collected from condensate or smoke.

It is possible to put a good chimney with your own hands and bring it through the wall, observing the conditions of regulatory documents. Despite the absence of difficulties during installation, this work requires certain skills.

Professional advice

It is not recommended to reduce the diameter of the chimney opening, this can provoke a stoppage or decrease in draft. The chimney must be cleaned of soot twice a year, and the head part of ice, snow or condensation frozen on it. Sandwich pipes do not need additional insulation, except for the passage through the partition or wall. For this purpose, it is better to use refractory insulation and exclude the use of glass wool. The section in which the pipe runs through the wall must be insulated with ceramic or basalt wool, asbestos or foamed vermiculite. The use of asbestos does not cause problems; at the final stage, the product will not begin to dust and release hazardous substances.

When working with walls made of wood, it is necessary to remember about the danger of fire, therefore it is much more difficult to install chimneys in such buildings when compared with brick ones. When the chimney is taken out through a wooden wall, it is necessary to strictly observe the distance from the pipe to the wall, it should not be thicker than 260 mm. Additionally, you need to take care of the insulating part and treat the walls with fire retardants. When placing a chimney in such a structure, it will be necessary to isolate the surfaces of the walls near the monotube and the outlet pipe from the heat generator. This insulation is created using combustible materials such as tiles, plaster, stone or metal sheets.

The walls of buildings made of bricks, concrete and aerated concrete are much more resistant to fire. But they must be insulated without fail in the places where the pipes pass, before they are brought out to the roof through the hole to the desired floor, keeping the distance to the walls not exceeding 130 mm.