When building a country house, all engineering communications are carefully calculated, including elements of the ventilation system of the selected type. Without a well-equipped canal designed to organize natural or forced removal of polluted air, not a single commission will accept the rebuilt housing. Therefore, it is so important to understand the features of the ventilation output to the roof of the building and familiarize yourself with the procedure for its installation within the roof space.

Things to Consider

In one- or two-story suburban-type buildings, ventilation pipes to the roof, coming from living quarters, kitchens and bathrooms, must be taken out in a special place prepared for this. With their arrangement, the vertical structure rises directly above the roof and allows you to get maximum traction. According to SNiP, when designing such a conclusion, it will be necessary to take into account the following points:

- All vertical sections of the future engineering structure are made even (without bends), which guarantees free air outlet to the outside.

- It is not allowed to combine several air streams together; channels from living rooms, kitchen, attic and sewers are made separate.

- Ventilation outlets are installed as close as possible to the ridge or directly on it.

- If it is impossible to install a straight span over the shaft, a corrugated pipe is used, which allows connecting adjacent nodes laid at different angles.

- Be sure to equip the fan section - the channel connects the sewer riser with ventilation and allows you to remove unpleasant odors.

- Air exchange is required, organized in the attic or in the attic area of the building.

In reality, the owners of private houses have to equip ventilation in an already finished building. In this case, it is necessary to take into account the peculiarities of the layout of all premises in the house.

Selecting the type of pipes

According to standard projects, the following types of pipe blanks are used to design ventilation ducts on the roof:

- asbestos-cement;

- based on PVC;

- typical sewer products, the diameter of which varies between 110-200 mm.

Ventilation in a private house with access to the roof is sometimes designed as a superstructure made of brick or concrete. In any case, the head of the ventilation duct is equipped with a special device that protects it from rain and snow - a deflector. Through such an umbrella, it is possible to increase traction in strong winds.

Benefits of roof outlet ventilation

The advantages of arranging air ducts on the roof of a house include:

- ensuring good traction, obtained due to the large difference in altitude (pressure);

- ease of arranging vertical structures with a minimum of turns and bends;

- the ability to monitor the state of the pipe head and its maintenance.

In addition, this approach to organizing the ventilation outlet allows you to combine taps from several types of engineering communications in one channel.

Specifications

The ventilation pipes presented on the domestic market have technical characteristics that depend on their type. Asbestos and ordinary sewage products are described by the following parameters:

- Basic standard size (working diameter).

- The degree of resistance to mechanical stress and the effects of chemically active environments.

- The temperature range in which they remain functional.

- UV resistant.

Plastic pipes are characterized by approximately the same indicators tied to the characteristics of a particular material. For example, polyvinyl chloride (or PVC) is resistant to UV rays, is not very expensive, the operating temperature range of pipes not based on it is from -10 to + 70 degrees. Most of all, it is suitable for arranging ventilation systems in bathrooms and kitchens.

Polypropylene is somewhat superior to PVC in its technical indicators, since it can withstand temperatures up to + 85 degrees. In addition, it is resistant to chemically aggressive environments and is available in a fireproof design. Fluoroplastic is characterized by an increased heat resistance (up to + 200 degrees), and is also resistant to UV and easily transfers contacts with active chemicals (alkalis and acids).

Polyethylene is characterized by a wide range of operating temperatures - from -50 to +80 degrees. It is UV resistant.

Features of installation of ventilation with access to the roof

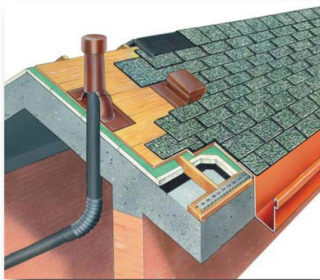

Features of the arrangement of ventilation are considered on the example of a typical air duct laid between the roofing and the ceiling of a residential building. It is very important to choose the right place for its output to the attic, in which important building elements should not be located. In addition, increased attention is paid to the layout of the ventilation under the roof, since the strength of the floor structures, in which a hole is made for the duct, depends on this.

The height and diameter of the pipe depend on the conditions in which it will be used, as well as on the type of ventilation and the volume of the room. Special attention is also paid to the following points:

- On pitched roofs, the head of the ventilation structure is made next to the ridge, which makes it possible to do without additional fixation.

- With this approach, most of the pipe is located in the attic or attic, where it is reliably protected from sudden temperature changes and strong gusts of wind.

- The exit to the roof is designed in such a way that rain and snow do not fall under the roof covering.

- To connect the individual elements of the duct, you will need special flanges, which can be purchased at any hardware store.

Particular attention should be paid to the tightness of pipes where they exit through the roof. For this, special shaped products have been developed, which are in the form of a branch pipe with a flexible metal base, outwardly it resembles a typical flange. During installation, it is tightly pressed against the roofing, taking the relief of the roofing material from metal, for example. During the installation of the duct outlet, they try to place this unit in such a way as to achieve perfect sealing of the joints.

The pipe itself, with a deflector installed on the head, is, if necessary, secured by means of special wire braces.

Ventilation pipe protection methods

Regardless of the material chosen, the roof ventilation pipe must be reliably protected from the following factors:

- mechanical (deformation) loads;

- climatic phenomena (snow and rain);

- accumulations of condensate in ventilation ducts;

- strong gusts of wind.

Unlike the option of an exhaust hood in a private house without access to the roof, in this case, additional protective measures have to be taken. In this case, the type of roofing material (corrugated board or a similar covering) is very important, depending on which a particular decision is made. When the pipe is brought to the surface, nozzles of a special design are used, which excludes the possibility of rainfall falling under it.On soft roofs, you will need to use several rubber pads to protect the surface from damage.

It is possible to eliminate the formation of condensate inside the ducts and their pipe extension in the following ways:

- insulation of the ventilation duct;

- moisture removal;

- replacement of the existing system with forced (supply) ventilation.

In the first case, it is recommended to use standard insulating materials (mineral wool, polystyrene or foamed polyethylene) for insulating air ducts. It is possible to remove the moisture accumulated in the cavity of the ventilation duct by arranging an additional pipe mounted on top of the main one. The latter option is used in cases where it is not possible to get rid of the condensate by other means. Guy wires will help to protect the pipe from strong gusts of wind.