Gas boiler ventilation

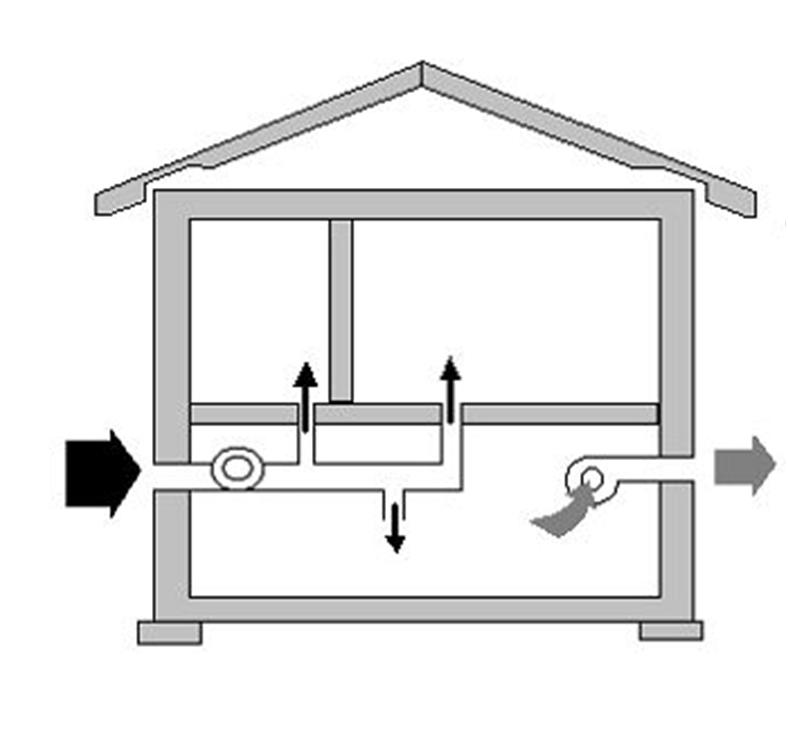

Boiler ventilation is installed with natural draft only. Forced ventilation can be dangerous in the event of a gas leak or boiler breakdown.

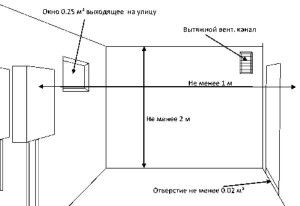

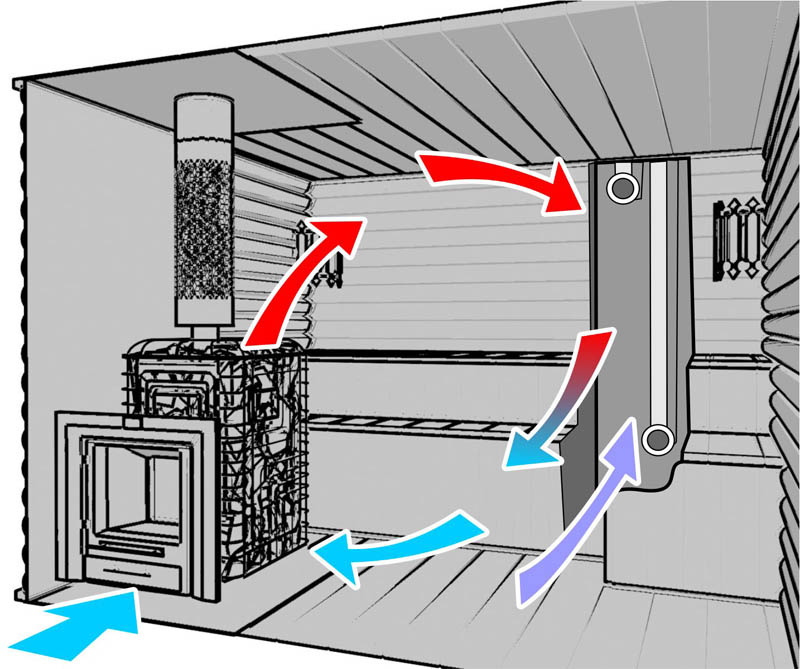

Exhaust ventilation for a gas boiler provides for a chimney. Since the hot combustion products are less dense than air, they are removed through the chimney from the boiler to the street. The colder it is outside, the more efficiently such an exhaust system will work. The calculation of ventilation when installing a gas boiler provides for:

- Blowing out per hour is equal to three times the volume of air in the boiler room;

- The inflow replenishes the extracted air plus provides the volume of air burnt in the boiler.

The parameters of the chimney are determined based on the temperature difference, the cross-section of the pipe and refer to the compulsory ventilation calculations when installing a gas boiler. Draft will be poor if the chimney runs down the street and is not insulated.

Features of ventilation for a gas boiler

From the ventilation pipe for a gas boiler to the walls, there must be at least 5 centimeters (if the walls are wooden at least 25 centimeters). It is allowed to make no more than 3 turns of the chimney. Air supply is provided only by natural supply ventilation for the boiler. The easiest and most effective way to supply air to the boiler room is to install a vent.

But when this is not possible, a supply air valve or an infiltration valve is installed. The valve is a pipe, the length of which is determined by the owner, depending on the thickness of the wall. The diameter is selected depending on the power of the boiler (from 80 to 160 mm). The valve itself is put on the pipe from the inside. Even in the most severe frosts, the device is not covered with ice. This is a very convenient and inexpensive solution for supply ventilation for the boiler, providing the necessary amount of oxygen to the burner and preventing the room from cooling down, as it can be with a conventional window.