Much attention is paid to the arrangement of the kitchen. This is a room that should have all the necessary elements of comfort and convenience. These devices include a hood, which removes unpleasant odors and purifies the air. The air duct is an important part of the system. To work effectively, you need to choose the right device and install it.

The difference between the hood and the ventilation system

According to the existing sanitary standards, devices that support air exchange must be installed in any living room. In connection with these requirements, a ventilation system is being made in an apartment building. It is a chain of channels that are located in the walls and bring air masses to the roof. Fresh air enters the apartment through the cracks in the door and window openings. Such a system is not able to quickly remove unpleasant odors that form in the kitchen during the cooking process.

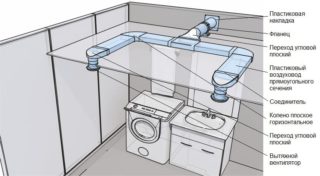

Compulsory ventilation systems are used to effectively remove odors. They are also called hoods. Their principle of operation is based on the absorption of vapors that come from the hob. After that, the air masses are discharged by means of an air duct into the ventilation duct. Instead, new fresh air flows from windows and doors.

Duct classification

Air ducts for hoods in the kitchen can be divided into groups according to different indicators: material of manufacture, performance, type of construction. Ventilation for the hood in the kitchen is selected individually for each room.

By design type

All products can be divided into two types:

- Flexible. Can be placed at right angles. They can be compressed and stretched, but it must be borne in mind that a weakly stretched duct has better resistance to air flows. Usually such structures are made of aluminum. The disadvantages include the impossibility of creating a corrugated box with a length of more than 3 meters due to a decrease in system performance.

- Tough. They are characterized by ease of assembly and have a smooth and even inner surface. The air flow is unobstructed due to its smoothness, which is why such systems are more efficient.

The cost of rigid models is higher, but their positive qualities justify the costs. The choice of system is determined by the number of bends that the pipes must pass. It is recommended to reduce the number of turns to avoid turbulence.

By form

There are several main options:

- Rounded. These are products that are used in homes with high ceilings. Due to the design and size of the duct, they are rarely installed. When connecting to a ventilation duct for a square or rectangular hood, you will need to use special connectors.

- Rectangular and square. Universal air ducts, which are most often installed in houses and apartments. The installation can be done behind the cupboards in the kitchen. There is a possibility of laying along any trajectory.

- Oval. They have similar characteristics to rounded models.

- Flat. This is a subspecies of rectangular structures that are almost invisible.

Rectangular structures are used more often than other types. Manufacturers produce products in several sizes.For hoods with a capacity of not more than 300 cubic meters / hour, air ducts with a cross section of 110 × 55 mm are used. For devices with a capacity of 350 cubic meters per hour, products of 120 × 60 mm are suitable. Devices with a capacity of up to 1000 cubic meters / hour require a section of 240 × 60 mm.

Based on materials

Air ducts made of plastic and various metals are popular. Each material has its own characteristics and advantages, which will be realized in certain conditions.

- Plastic. These are the most popular designs for kitchen hoods. They are round and rectangular in shape. The main advantages include corrosion resistance, ease of assembly and installation of the exhaust pipe, smoothness of the walls, low price and low weight. During operation of the hood, such systems do not emit noise. The disadvantages include the need to purchase adapters and connectors for connecting parts, as well as instability to high temperatures.

- Aluminum. Structures for ventilation systems are often created from this material. The advantages include low price, simplicity and versatility, ease of installation, resistance to high temperatures. However, aluminum has serious drawbacks that limit its use - it is high thermal conductivity, due to which condensate will accumulate; unpresentable appearance and weak structural strength.

- Steel. For air ducts, stainless or galvanized steel is selected. It is a durable material that is inexpensive, has an even base, does not deform and does not emit harmful substances. The popularity of steel products decreases every year. This is due to the need to use the most reliable and stable clamps, the complexity of cutting metal pipes, heavy weight and noisy operation.

Despite the reliability, metal air ducts are used less and less. They were replaced by plastic products.

Selection Tips

The arrangement of the ventilation system requires the owners of a house or apartment to take into account all the features of the premises. To facilitate the choice, you need to follow the recommendations:

- You should buy equipment only in official stores. The kit must include instructions and a warranty card.

- Exterior design must also be taken into account so that the hood with an offset air duct fits into the interior.

- Brand and product value. It is recommended to take air ducts from trusted companies with an optimal price-quality ratio. It is better not to buy cheap products, since their characteristics will not correspond to the declared ones.

- Performance. It should be sufficient for a particular room. In the case of poor ventilation, the air flow will be renewed more slowly, unpleasant odors will stagnate.

- Low noise level.

- The ability to quickly remove extraneous odors.

When planning the system, it is recommended to use the principle of minimalism - the fewer turns and additional parts, the more efficiently the duct will work. In the case of a cooker hood, a duct with three turns is sufficient. An increase in this value leads to a decrease in efficiency by 10-15%.

Bandwidth is the main selection criterion. The cross-sectional area on which it depends must be commensurate with the air outlet pipes. To determine the section, use the formula S = 3.14 × (d / 2) ² for round pipes, where d- the diameter of the duct; and also for rectangular S = L × Hwhere L and H - length of 2 sides of the structure. There is no need to add a margin to the obtained values, since it will not affect performance.

The installation of an air duct for a kitchen hood can be done independently. Before you do how to make an air duct for a kitchen hood with your own hands, you need to create a plan for its placement and choose a way to mask the pipes.

Installation features

The air vent for the hood can be supplied by hand. Corrugated products are the easiest to install. They are cut into pieces of the desired length using ordinary scissors or a hacksaw, and then attached to the ventilation shaft and hood. For more efficient operation, it is recommended to replace the regular grille with one that has a connecting pipe. The fixing of the air duct is carried out on special clamps. The contact points should be treated with sealant for greater strength.

In a similar way, PVC air ducts are installed. Using a hacksaw for metal, the pipe is cut into parts of the required size, after which they are switched using clamps. It is important that the pipe goes into the branch pipe at least 5 cm. The contacts are worked out with a sealant.

If a cooker hood with a capacity of more than 600 cubic meters / hour is used in the kitchen, back draft may occur. Check valves are used to combat this phenomenon. They are sold in the form of a plastic disc on an axle or filmy. The installation of the product is carried out vertically so that there are no false alarms under its own weight.

Duct decor methods

Pipes adjacent to the hood and vent can spoil the design of the room. For this reason, the owners of the apartment decide to hide it. There are several ways to disguise the air duct:

- Plasterboard sheathing. A crate is made along the duct, on which sheets of drywall are fixed. Further, the resulting box can be finished in the same way as the entire room. An important disadvantage of this method is the complex approach to pipes if necessary.

- Plastic box. Manufacturers offer ready-made plastic structures in which the duct can be placed. This is a simpler and cheaper analogue of plasterboard sheathing.

- Installation of pipes above a suspended or stretch ceiling. In this case, the structure should be planned even at the stage of renovation before finishing work. The air duct is laid over the ceiling structure, after which the coating itself is installed. If you need to access the pipes, you will have to disassemble the ceiling, which is a significant drawback.

- Built-in hood and air duct in furniture and kitchen sets. A cabinet is hung on the wall through which the pipes will pass. This method has an important drawback - a visual reduction in space.

- A budget option for the previous method is to use a hanging canopy on the cabinet. Then the box is not mounted under the ceiling, the duct pipes are taken out of it upward and connected to the ventilation shaft. From above they are covered with a visor.

- Laying the duct close to the wall. Suitable for high and deep cabinets that protrude significantly above the surface. Then the pipes will not be visible.

- Painting. This is the cheapest way. The duct is painted in colors that match the interior. It is important to choose the right coloring composition so that it also protects the pipes.

For small kitchens, methods with a cabinet are not suitable due to the visual reduction in space. The best option would be to lay pipes above the false ceiling or use ducts and paint.