Artesian wells have many advantages, but the construction itself is expensive. Whether or not to make a well in limestone is a matter of finances, but subsequently there will be fewer problems with operation than with cheap Abyssinian and sandy sources.

Artesian well and its varieties

Further, there is groundwater. They lie on a water-resistant layer of clay, on which there is an aquifer of sand. The liquid is absorbed over the entire area of the water vein, and may contain residues from septic tanks or livestock farms. To use the well constantly, you need to ensure the purity of the source. In sand wells, the liquid level changes depending on the season, but mostly there is water all year round.

Interstratal water veins are protected by a waterproof layer located on top, so the liquid in them is cleaner than in the sand layer. In some places, they can combine, so the water is first checked for chemicals and organics. If there is a clean hole in the area, there is no need to drill deeper.

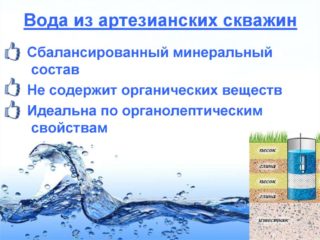

Artesian wells provide the purest water that exists in nature. The recharge source is usually located very far - tens and hundreds of kilometers from the water intake. It can be a deep river or sea. The fluid circulates in layers of limestone, gypsum or marl. They can be pressure or non-pressure. The latter are very rare. Artesian basins are multi-level vertically located aquifers that occupy vast areas.

The depth of an artesian well can be up to 300 meters. Despite this, the level of the liquid is always higher than the level of the aquifer, since the pressure pushes it closer to the surface. In mountainous regions, the artesian layer may be shallow, which facilitates the drilling process.

Advantages and Disadvantages of Limestone Wells

- inexhaustible supply of water at any time of the year;

- absence of seasonal fluctuations in the liquid level, which is a safe moment during the operation of submersible equipment;

- no maintenance is required, unlike sand wells, which need to be cleaned every 5 years;

- service life of more than 50 years, subject to correct installation and use of high-quality materials for the casing;

- quick self-sufficiency of the source, if the water has useful qualities, but then it will be necessary to drill more than 400 m in depth.

There are also downsides. Each region has its own chemical composition of the liquid, since the formations can contain various substances, the ions of which enter the water. It may be necessary to install additional filters to reduce the amount of iron or magnesium.Magnesium gives a bitter taste, and iron precipitates after exposure to air and also has a not very pleasant taste of rusty nails. Excess calcium makes the liquid hard. It is problematic to wash your hair with such water, and it negatively affects the condition of the skin.

The prices for drilling artesian water wells are quite high. Given the depth, the source together with a set of pumping equipment can cost about 100 thousand rubles or more. It is almost impossible to drill an artesian well on your own, so they turn to specialized firms for help.

To obtain permits for the construction of a well on limestone, you need to spend time. Such a document is not required for the construction of a conventional needle well.

Drilling technology

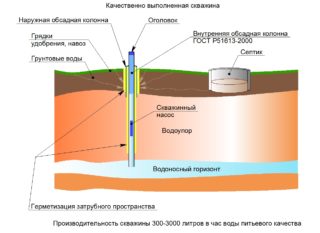

An important rule is that plastic pipes cannot be used at a depth below 25 meters - they deform when soil layers shift, and dirt gets into the water. Metal casings are also not an option, since rust quickly forms on the walls, which passes into water.

Companies that value their reputation suggest not to save money and to make the outer pipe from metal, but the inner one from plastic. It will cost more, but the design will be reliable. It is very problematic to change the pipe at a depth of over 100-200 meters - you will have to get all the casing, and this is the cost of one more well.

Drilling is carried out using several methods:

- rotary rotor with direct flushing;

- blowing;

- backwash;

- shock method.

90% of all artesian wells are rotary with direct mud flushing. The drilling rig is selected depending on the expected drilling depth, the width of the shaft diameter.

An important point: to protect clean artesian water from groundwater, insulation is used. Usually they use an expensive clay that swells in a humid environment and prevents mixing of aquifers - compactonite. Before concluding a contract, you need to find out what type of insulation the company works with, since the material can be cheap and will not perform its functions.

After installing the casing and insulation, the pipes are washed with clean water and samples are taken for analysis. Further, the well is commissioned together with a technical passport.

Operating rules

After completion of construction work, it is necessary to install a submersible pump or pumping station if the distance to the water mirror does not exceed 8 meters. Over the next 3 to 4 months, you should monitor how the fluid level in the well changes so as not to damage the pumping equipment. If the level does not change, then there is no need to lower the water inlet hose or submersible pump below.

The top must be sealed to prevent dirt or organic matter from entering the pipe, which could cause bacterial contamination of the water.

Design options

To obtain a permit for construction work, you need to issue:

- drilling license;

- a license for the well itself.

If you contact the company officially, they prepare the documents themselves and register the source. Delays are possible in case of self-registration.

The first step is to write an application to the Ministry of Natural Resources, after which a commission is created, which decides whether it is possible to equip the well in the selected location. Further, the owner of the site collects documents, receives permission from Rospotrebnadzor and approves the well project in Oblkomvod. All papers are transferred to the Subsoil Use Department, after which a license is issued, which gives the right to apply to companies that are officially engaged in drilling, have a license.

After the completion of construction work, an examination of the structure and analysis of the water is carried out, the conclusion of the relevant authorities is issued. The source is entered in the cadastral register. It is important that by the time of commissioning the first belt of the sanitary zone has been equipped.

To obtain a license for a well for an individual, it is necessary to pay a fee in the amount of 500 thousand to 1.5 million rubles. For legal entities it will cost 2 times more. Document production time - up to 1 year.