If in winter, in a severe frost, you turn on the water tap, and the water does not flow, then most likely the pipe is frozen.

Why did this happen? This could happen for several reasons:

- the pipes were not deep enough, they lie at the level of soil freezing or higher;

- low quality insulation or its absence;

- the water supply is turned off, or the flow is very low.

If the pipeline is installed at a shallow depth, and it is possible to access it, it is required to determine the freezing area and warm it up.

- How to determine the location of freezing

- Required tools and materials

- The main methods of heating pipes

- How to warm up a pipe from the outside

- Heating the pipe with hot water

- Warming up from the outside with a building hairdryer, a heat gun

- Using a fire, blowtorch, or torch

- Heating cable application

- Using a welding transformer

- How to warm the pipe inside

- Defrosting with hot water

- Using a steam generator

- Making and using a homemade heater

- Preventive measures

How to determine the location of freezing

- First, we examine the pipeline at the entrance to the house. This is a likely problem area.

- We are looking for an area with thermal insulation - freezing may occur there due to damage to the insulation. We check the joints.

- We inspect the condition of the entire pipeline. If the material is plastic, then a fragment with an expanded diameter signals the presence of an ice plug.

- We check the pipe by touch: the section with ice is colder, it may be covered with frost.

- If it is not possible to conduct a visual inspection, unscrew the tap, insert a plumbing cable into the pipe. We measure the length of the problem area.

- A complex pipe with many bends? We disassemble it and insert the cable into an accessible place.

- There may be several frozen areas.

Required tools and materials

Depending on the selected heating method, you can use the appropriate appliances and accessories.

Instruments:

- building hair dryer or heat gun;

- torch or blowtorch;

- welding transformer;

- steam generator;

- small pump for diesel fuel;

- 12v power supply (from a screwdriver).

Materials:

- metal-plastic pipe;

- water tank;

- copper wire 2 * 1.5mm

- a tube from the hydraulic level or a hose from a dropper up to 2 m long;

- heat insulating materials: fiberglass, basalt shells, polystyrene foam insulation;

- rags for winding pipes.

The main methods of heating pipes

It is important to choose the correct method for removing the ice block depending on how the piping is installed. If it is possible to free the water supply from the ground, and there is access to it, we defrost it outside.

How to warm up a pipe from the outside

- open the tap, which is located closest to the place of the ice plug;

- we work slowly, moving from the beginning of the plug to its end;

- we make sure that the pipe does not overheat during the defrosting process, otherwise a rupture may occur;

- the appearance of a few drops of water indicates the correctness of the actions;

- after the water flows in a trickle, stop heating. It is not necessary to completely melt the area; the moving water will eliminate the remaining ice.

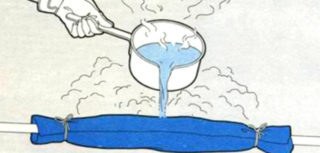

Heating the pipe with hot water

This is the easiest and most affordable way. Its disadvantage lies in the need to prepare a large volume of hot water, as well as in the continuous cleaning of dirty stains and puddles on the floor. How to heat properly.

- We wrap the frozen area with rags.

- Pour hot water; the degree of heating should be increased gradually.

- This is a long procedure, it will take 20-30 minutes of continuous exposure.

Warming up from the outside with a building hairdryer, a heat gun

- We increase the air temperature gradually so as not to rupture the structure;

- We heat plastic pipes longer than metal ones; but do not overheat, otherwise they will melt.

Using a fire, blowtorch, or torch

This is a dangerous method because we use open fire.

- Place asbestos cardboard under the heated place.

- Lead the process slowly and carefully.

Only metal pipes can be heated this way.

Heating cable application

It is useful to have this device in the house and use it not only for defrosting any pipes, but also for preventing freezing in severe frosts.

Using a welding transformer

- We connect the welding wire to the area with the ice plug.

- We apply current for 30 seconds.

- Turn off for 10 seconds.

Observe safety precautions:

- do not come closer than 3 m to the heated area;

- do not touch any metal surface of the system with bare hands.

Can only be used for metal pipes.

How to warm the pipe inside

If the pipe is located underground, and there is no access to it, then in this case it is possible to cope with the misfortune.

To resolve this situation, use the following methods.

Defrosting with hot water

- We prepare containers for collecting waste water that will flow out of the gap between the pipes.

- We push a metal-plastic pipe with a diameter smaller than the water pipe into the problem area up to the ice plug.

- Pour hot water into the pipe using a funnel, or better - an injection pump.

- As the cork thaws, push the thin tube further to the ice cork.

Instead of a metal-plastic pipe, you can use a tube from a dropper or a hydraulic level, and make a device for injecting water yourself.

- We use a pump for diesel fuel. As a power source, you can take a battery from a 12 V screwdriver.

- You will need table salt for the brine to keep the effluent water from freezing.

- We connect the tube from the dropper up to 2 m long to the pump, push the other end into the line until it contacts the ice plug.

- We lower the pump into a container with hot brine, plug it into the network.

- As the ice melts, we push the pipe further until the congestion.

- If possible, we constantly heat the container with salt water on the stove or with the help of a heater.

Using a steam generator

- Pour water into the reservoir of the steam generator

- We attach a heat-resistant hose to the device.

- Insert the other end of the sleeve into the frozen pipe until it contacts the congestion.

- We turn on the device.

After 10-15 minutes, the ice will begin to thaw

Making and using a homemade heater

- On a copper wire with two insulated conductors, each of which has a cross section of 1.5 mm, we remove the outer winding at a distance of 10-15 cm.

- We strip one wire, bend the other at an angle of 180 ⁰ and press it against the main cable.

- We wind the bare wire on the cable with the pressed wire to the point where the insulation ends. For better heating, gaps should be left between the turns.

- We also strip the other wire from the braid, retreat 3 mm from the wound turns and also wrap the insulated core. Both wires must not touch each other.

- We attach a plug to the other end of the cable.

- The resulting device should be tested in a jar of water.

- We insert the heater into the pipe until it touches the ice plug.

- We turn on the plug into the socket.

As the ice melts, push the heater deeper to the plug.

Preventive measures

So, we thawed the pipe. But what should be done so that this trouble does not happen again?

- If an ice block forms at the exit of the pipe from the house, insulate the hole, it may need to be widened.

- Insulate open sections of the pipeline with heat-insulating materials.

- Use a self-regulating cable. In this case, it is enough to turn on the system several times a day for 15-20 minutes.

- In case of severe frost outside, keep the water tap ajar. The flow of water will keep it from freezing.

- Purchase and install a backup generator in case of a power outage.

- If you do not use the water supply during the cold season, it is better to drain the water.

Freezing of the pipeline in severe frosts in winter is a common problem faced by owners of private houses. The ways to resolve the situation outlined in the article will help you cope with the task yourself. In difficult cases, it is worth contacting specialists. They have a hydrodynamic machine that will break the ice in the system much faster.

Too much and not about anything. At a depth of 2 meters, a frozen pipe cannot be warmed by a fan, boiling water, or a welder. He warmed the polyethylene pipe with a simple boiler of 2 pieces of a hacksaw blade for metal. Took and broke off the extreme parts of the canvas with holes, where- then 4 cm. Between them I put 2 matches and tied them with threads. In places where the holes were, I connected 2 wires and brought the whole structure into a nylon corrugation. He brought the boiler outside, and insulated the output with electrical tape. Pushed the entire structure all the way into the ice and turned on the boiler in 220v Gradually pushing it forward, I went through the entire plug in a few minutes.