A well is a common source of water supply for private houses. The rise of the liquid from the depth and the filling of the line is provided by the pump. Frequent turning on and off cycles of the unit lead to wear of the parts. To organize a safe mode of operation, a borehole pump control unit is installed.

Appointment of automation for the well

Automatic control devices for submersible pumps are used to monitor their operation and protect against abnormal situations. Electronic or mechanical devices maintain the pressure parameters set by the consumer in the water supply network. In the event of emergencies in the form of voltage drops or lack of water, the automation prevents the breakdown of an expensive unit.

Main components of the control unit:

- Pressure switch - provides activation and deactivation of the pump in accordance with the setting of the minimum and maximum pressure thresholds in the water supply system. The controller can be equipped with a pressure gauge and a dry-running sensor.

- Float switch - installed on the pump, used to control the liquid level.

- A hydraulic accumulator is a sealed metal container with an elastic membrane inside, into which water is pumped. Part of the tank is filled with pressurized air. The device is necessary to maintain a stable pressure.

- Press control or flow switch - the device has a check valve, serves to turn on the pump when the pressure drops. The device shuts down the unit in the absence of liquid ("dry running"). Used in a system without a hydraulic accumulator.

Automation reacts to changes in the physical parameters of the liquid: pressure, flow rate. Special relays control power surges and protect the motor windings from overheating.

Types and device of automation

According to the degree of automation, control units are divided into three generations.

First generation

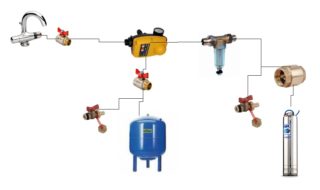

The simplest type of automation for a borehole pump with a hydraulic accumulator and a pressure switch is widely used. It is available for self-assembly and maintenance. The control devices are compatible with submersible and surface units. The size of the storage tank depends on the total water consumption. The pump is supplied with electricity through a pressure switch. When the pressure in the system drops, the contacts close, the pump turns on. It functions up to the upper pressure threshold. The cycle is repeated regularly. The hydraulic accumulator reduces the number of starts of the unit, compensates for water hammer.

Second generation

Automatic control is carried out by a unit with a set of sensors. Its basis is press control. The device provides adjustment of the supply and pressure of water in the system. In the event of an alarm, it turns off the pump, performs an automatic restart. The electronic regulator receives signals from sensors in the pipeline. The device is quiet and requires no maintenance. The device is installed up to the first draw-off point. There is an arrow on the body showing the direction of fluid movement. The units operate without pumped storage tanks.

Third generation

The latest generation automation systems control the pump motor speed. It reaches its operating power only with a significant water consumption. A smooth start is carried out, the resource of the mechanism is slowly developed, and electricity is saved. Such devices are frequency converters. Automation has fine settings, provides reliable protection of the engine from faults in the electrical network. The head in the system remains unchanged when several points of consumption are switched on at the same time. To compensate for leaks, it is recommended to install a 2 liter tank. The cost of a frequency converter is much higher than the rest of the automation, it is 17-35 thousand rubles.

Principle of operation

Regardless of the level of automation, the borehole pump control system works according to the general principle. It turns on the unit when the contacts of the pressure switch are closed. The device is configured for two parameters: the upper stage, at which the pump is turned off, and the lower, which starts pumping water into the system. A dry-running sensor is installed in parallel or in the same housing. It prevents the mechanism from running dry. Installation of a relay may not be necessary if the pump is equipped with a float mechanism.

In modern automation systems for wells with submersible pumps, electronic control units are used. The devices do not require the installation of a hydraulic accumulator. They function based on the readings of pressure sensors located in the pipeline.

Criterias of choice

Control systems are selected according to their technical characteristics. Their parameters must correspond to the pressure criteria of the borehole pump and the water supply needs of the house. If the unit is designed to use a small amount of water, a float switch is sufficient. For the correct operation of a system with an average water consumption, a pressure switch and a hydraulic tank are required. The number of points for parsing the liquid and the pressure requirements are taken into account.

Control units of the second and third generation of automation provide effective control of the pump operation, provide reliable protection against any overload. They are recommended for installation in country cottages with permanent residence. A simple system of a relay and a storage tank is best used in the country. In this case, water supply is required only during the warm period; there is no need to purchase expensive equipment.

The price of electronic and frequency units is much higher than that of the first generation devices. Taking into account the maintenance and repair of high-precision devices, few consumers choose modern automation. Electronic regulators in terms of technical characteristics surpass a set of relays and a hydraulic accumulator, but the cost makes them inaccessible to the mass buyer.

Features of installation and connection

The consumer can independently install the float switch and the first generation control system. It is better to entrust the installation of electronic regulators and frequency converters to specialists. Control devices are placed in a heated dry room. The pressure switch is installed on a five-way fitting in front of the inlet to the accumulator. The rest of the inputs are connected: with a pipe from the pump, wiring to the parsing points, a pressure gauge. A check valve is cut in the area between the pump and the tank.

The float mechanism and protection against "dry running" are installed on the pump before it is lowered into the well. For the correct operation of the control units, the installation of filters is required.

Customization

Self-setting of parameters is possible only on a mechanical pressure switch. It is carried out with an open case. There are two springs inside the device. Turning the larger part adjusts the pump activation pressure.Loosening and twisting a small spring changes the difference between high and low pressure.

It is recommended to check the air pressure in the hydraulic tank before starting the system. When lowering the factory parameters, it is necessary to pump it up with a compressor.

Advantages and disadvantages of using automation

- Full control over the functioning of the water supply network is carried out.

- Manufacturers assemble all automation units in a compact electronic unit.

- The use of a regulator increases the life of the pump.

- Maintaining a constant pressure provides a comfortable use of plumbing fixtures.

For the convenience of consumers, the units are equipped with digital displays for monitoring parameters. In the event of a failure, they restart themselves.

Disadvantages of automation:

- The functioning of electronic devices depends on the voltage in the electrical circuit.

- Control units are expensive.

- Control systems are not suitable for vibration pumps.

- The factory settings of the devices are not always suitable for a specific network; only a specialist can perform the adjustment.

For consumers, the main selection criterion remains the cost of control systems. The use of the first generation automation is advisable in combination with an inexpensive pump.