The provision of continuous water supply is carried out thanks to a number of structures and mechanisms, for example, water intakes, pumping stations and filtration stations, pipelines, etc. Automation of water supply and sewerage systems makes it possible to coordinate the work of individual mechanisms and structures.

Requirements for automatic water supply installations

Process automation is applicable to the following water supply systems:

- treatment facilities;

- artesian wells;

- booster stations;

- filter stations;

- stations of the first and second level of the ascent.

It should be borne in mind that the process of extraction, filtration and transportation of water is associated with various chemical, biological and physical reactions.

Water supply automation is carried out taking into account the following requirements:

- The intensity of the work of the working units must constantly change, taking into account the needs of the system.

- If one equipment is out of order, all other sections must operate normally.

- Primary water characteristics are unstable.

- The work takes place continuously and in an economical mode.

- The working units are installed at remote points, and they are controlled remotely from the work center.

- Strict requirements for the quality of water supplied to the consumer.

For the smooth operation of the entire system and each working unit, you need to correctly draw up a project and complete all the components.

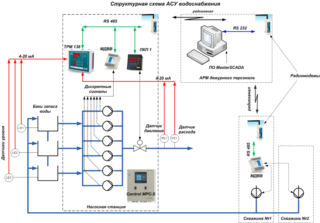

Automation system device

- controller;

- measuring transducers;

- executive mechanisms;

- sensors for measuring liquid flow;

- data input and output blocks.

Sensors are needed to regulate automatic processes and transmit information to the work site in the event of a problem.

Blocks, they are modules, outputs and inputs convert and transmit information received from sensors to controllers.

To transfer information from the periphery to the control center, the following is used:

- satellite connection;

- radio channels;

- wireless Internet;

- switch;

- mobile connection.

Also an integral part of the device is the actuator. It is needed to receive a signal from the controller and convert it into an action. The diagram of the automated water supply actuator includes a motor, a relay, a pneumatic and a hydraulic drive.

Design of automation systems

- The entire process of water supply from receipt to delivery is automated.

- Operators should be able to remotely change pump parameters from the control room.

- Continuous monitoring of the quantity and quality of the extracted resource, the status of the equipment is displayed on the dials.

- All information is archived in the controller's databases.

Water supply automation should ensure continuous and uninterrupted water supply to all consumers, regardless of the seasons, weather conditions, etc.

Installation steps

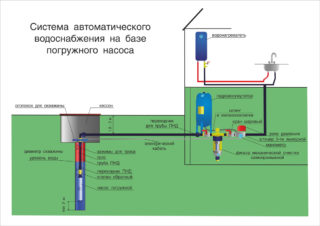

Often in rural areas, at the stage of project creation, there is no central water supply. Either there is a common pipeline, the pressure is weak, consumers often suffer from a cutoff of the water supply, or its quality does not meet sanitary standards.As a rule, there is only one solution to the problem - the search and drilling of a well, which will provide guests with the necessary volume of drinking water. This process is laborious and costly. The installation steps are as follows:

- Drilling and well construction.

- Purchase of correctly selected pumping equipment (pumping station or pump).

- Installation of equipment.

- Installation and arrangement of the pipeline.

- Installation of a hydraulic accumulator.

- Installing controllers.

- Electricity connection.

The well needs to be equipped with a caisson. This is a rectangular or cylindrical depression in the soil. As a rule, the depth of the pit is 2 meters, its walls are lined with reinforced concrete slabs, which are in close contact with each other. The caisson should rise above the ground by no more than 200 mm. It is also equipped with good waterproofing.

The well-coordinated and correct functioning of all components increases the reliability and efficiency of the automated water supply system, reduces costs and leaves the final indicators of tap water in the norm.