Pressure units with a hydraulic tank are used in autonomous and centralized water supply systems. The storage device is installed in a heated room or in a caisson near the well at a depth below the freezing point of the soil. The stability of the system depends on the correct choice of the tank.

Purpose and device of the tank

Hydraulic tank for the pumping station:

- maintains a constant pressure in the water supply network;

- reduces the frequency of switching on and off the supercharger;

- protects the unit from wear;

- protects against water hammer.

A pressure unit equipped with a hydraulic tank is more economical in terms of electricity and water consumption.

Types and principle of work

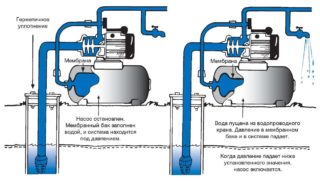

The storage tank for the pumping station is used to resist water hammer and keep the water supply. The expansion analog, in addition to these functions, additionally stabilizes the pressure in the water supply line. It is divided by a membrane partition into air and water compartments and works according to the following principle:

- By means of an electromechanical switch, the maximum permissible pressure in the tank is set.

- During the operation of the station, liquid is injected into the water compartment.

- The air in the second chamber is compressed, the pressure increases.

- Having reached the highest allowable limit, the pump turns off.

- The equipment starts up when the pressure drops to a minimum.

When a small volume is consumed, water will flow into the mixer from the tank, while the pumping equipment will not start.

The expansion tank for each model of the pumping station has design features. Devices with built-in and replaceable diaphragms are produced. The latter options are preferable, since in the event of a rupture of the "pear", it is quite easy to change it. The element is removed from the accumulator through a flange mount on the neck of the structure. During repair work on a hydraulic tank with a large internal volume, you will first need to check if there is an additional diaphragm fastening on the side opposite to the flange.

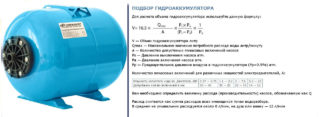

Criterias of choice

The larger the volume of the hydraulic tank and the lower the water consumption, the less often the automation starts the pumping equipment. More than six starts per minute results in a 20 percent increase in blower wear. When started more than ten times per minute, the wear rate increases by 30-40 percent. Also, small tanks hardly protect against water hammer.

Hydraulic tanks can be installed in two positions: horizontal or vertical. If space permits, purchase the first option. With a shortage of areas, a vertical device is chosen.

Pay attention to the material of manufacture. Steel tanks are more reliable because plastic is prone to deformation.The presence of a membrane protects the metal walls from corrosion. But steel structures are more difficult to mount due to the significant mass.

Installation features

When installing, you need to take into account the possibility of access to the accumulator. The device is connected to the water supply system anywhere after the pump and non-return valve. The device must be grounded.

Connection diagram of the unit to the pressure plant, depending on the pumping equipment:

| Pump type | Connection procedure |

| Submersible, semi-submersible | Pumping station - non-return valve - hydraulic tank - pressure sensor. |

| Submersible centrifugal and surface centrifugal | Pumping station - non-return valve - hydraulic accumulator - second pump - pressure sensor. |

When installing a surface pump, the accumulator is located near it. If an intake of 20 liters of water per minute is sufficient, in the latter scheme it is allowed to install both submersible vibration-type pressure devices. The design will come out much cheaper.

The connection of the hydraulic accumulator to the downhole pumping equipment is carried out in compliance with safety rules with the power supply disconnected to prevent accidental starting.