Owners of their own land plot need to do most or all of the work on the arrangement of communications on their own. It is important for the owners of summer cottages to have tools for all occasions. But in hardware stores, they are expensive, and not everyone can afford it, especially pensioners. To save money, you can make a drill for a well with your own hands.

Why do you need a hand drill

Every owner is obliged to have a hand-held drilling tool in his country house. Situations in which you may need to make a hole in the ground:

- If there is no centralized water supply, you can dig a thief to get drinking fluid from the underground aquifer.

- To build a greenhouse in the garden, you need to bury the mountings to a depth.

Also, the drill will be indispensable for arranging the landscape and water drainage system from a suburban area.

Drill types for wells

You can make a well with your own hands using the bailer method in several types, depending on your needs. There are three main types of drills:

- screw;

- shock;

- spoon.

It is not necessary to be limited to only one, you can make a drill in different variations. In all cases, certain tools will be needed, since it will not work to make a well without equipment by water pressure.

All three presented species perform the same function, but the scope and conditions in which they are applicable differ. A spoon tool is needed for small jobs on digging short bailers in soft soils. The screw (auger) is useful for medium-depth wells in not the hardest soil. To punch a hole in solid rock requires a massive percussion mechanism.

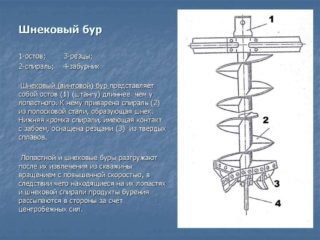

Screw tool

Operating principle

The tool is placed vertically above the place of the future bailer. Then you need to press on the handles so that the tip of the pipe sinks into the soil. Having exerted a physical effort, you need to start scrolling it around the axis in the direction at which the spiral-shaped plates begin to deepen into the rock.

The soil from the hole in the soil will be gradually delivered to the surface along the plates. The rock lying on the blades will exert additional pressure as the tool is immersed, which allows the worker to put less pressure on the handles with their mass. At the same time, efficiency is increased, since the owner is less tired and can continue the process for longer.

Making auger tools

To make a drill, you will need:

- pipe 1–1.5 m long;

- a pipe of a smaller diameter or an elongated metal plate of any shape up to 0.5 meters long;

- Bulgarian;

- welding machine;

- metal cone with a sharp tip;

- durable steel sheets;

- rubber;

- industrial glue.

The process of making a screw drill with your own hands begins with the preparation of a drawing. Draw a schematic diagram of the device itself and its details, write a sequence of actions.

Weld the cone to one end of the long pipe. This will be the tip cutting into the soil. Then attach a second pipe or steel bar on the back to act as a handle.The base is ready.

The next step is to secure the screw parts. Cut the sheet metal with a grinder according to pre-drawn shapes so that it can be bent and connected to the pipe with one of the edges. He needs to be given the correct shape and welded to the base. In conclusion, you need to take care of the convenience - to rubberize the handle. Apply glue to it, wrap it tightly with rubber and wait until it dries. The hand drill for the well is ready.

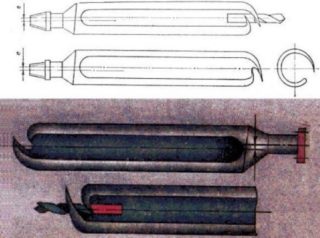

Making a spoon type

Unlike the other two, this instrument is compact in size. It is needed in order to quickly make a shallow hole in the topsoil.

How it works

A spoon drill is a device similar to a spoon: it has a length of 10 to 50 cm and the shape of a pipe twisted along its axis, which has a narrow hole on one side along the entire surface. A holding handle is located at one end.

To drill a hole in the soil with it, you need to take it firmly with a brush, set it at the required angle to the ground and push while scrolling. As soon as it begins to enter into depth, excess earth will leave the cavity through the longitudinal cutout located on the side. This drilling method is not suitable for medium to high hardness soils, as well as rocks, therefore it is used mainly for horticultural purposes.

How to make a spoon drill

You will need the following tools and materials:

- short metal tube, preferably thin-walled;

- metal carving machine;

- industrial glue;

- rubber for the handle;

- welding machine;

- small plate of sheet steel;

- a pair of vices;

- iron bar or large diameter bolt.

It is necessary to give the scoop part the correct configuration. Cut a narrow strip along the entire length of the walls to leave a hole. Secure with two different ends in a vise and rotate axially to make the tube spiral.

Since the pipe is hollow, one edge must be closed with a metal plate by welding, and then an iron handle must be attached to it. It needs to be coated over the entire surface with glue and wrapped with a layer of rubber so that you can hold the device with your bare hands. For easier entry into the soil, you can sharpen the edges of the pipe with a machine, making it sharper.

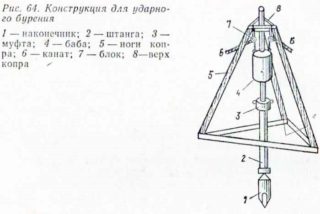

Impact drill for wells

What is a percussion drill

Drawings of a homemade drill for a water well in this case will be especially useful, since a more complex mechanism with a large number of parts is to be manufactured.

An impact drill is a kind of battering ram, which, with its own mass, punches a hole in the ground. It is great for making holes in dense rock where you can't manually make a bailer.

How to make a percussion drill

Required Construction Tools:

- three long strong beams or thick pipes;

- block for rope or steel cable;

- metal cable;

- weight for weighting;

- sharp tip;

- spring;

- pipe for the percussion mechanism.

A tripod is welded from metal beams, on which the entire mechanism will be held. It is advisable to collect it immediately above the drilling site so that it does not have to be moved. You can do it in two ways: just weld with a welding machine or make the structure collapsible for ease of transportation.

A block is attached to the junction of the beams, through which the cable should be pulled. It can be wound and released manually or using an electric motor.

It is desirable to give stability to the structure of the tripod. Install its feet into the grooves made with a punch. The impact mechanism consists of 3 parts: pipe, tip and weight. A weight can be attached from the top edge to make the impact with the ground more effective.

The impact mechanism must be connected to a cable, the other end of which is passed through the block.Now you need to pull on the cable to lift the drill up. From the highest possible height, it must be dropped to the ground. Repeat the method until the striking part reaches the desired depth.