A frequency converter is a device that regulates the process of pump operation without human intervention. It is included in most models at the stage of manufacturing the structure. In complex types of pumps, instead of converters, microprocessors are built in. In simpler models, where there is no converter, there is a need to purchase and install it.

Purpose of the device

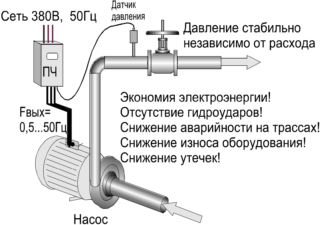

The inverter regulates the operation of the pumping system better than the relay, performing the functionality of the automation that regulates the working process.

- Protects pump motor from wear by reducing power supply and speed.

- Extends pump life by eliminating surges in electricity.

- Prevents the formation of more than standard pressure in the pipes.

- Saves energy.

The frequency converter looks like a small box, complete with a measuring sensor, boards and a voltage leveling inverter.

Principle of operation and device

An inverter converter is a complex electrical device. The kit includes:

- pressure sensor - determines the main indicators of the system;

- logic converter - compares pressure sensor information with input data;

- Control block.

When the pressure in the pipes changes, the water supply decreases. The sensor detects that the parameters of the pressure level in the hydraulic tank are lower than the set ones, and sends a signal to the logic converter, which starts the motor. The set of revolutions of the motor is smooth, which makes it possible for the system to reduce hydraulic loads. In modern models of frequency converters, it is possible to set the start time of the motor from 5 to 30 seconds.

During motor start-up, the pressure sensor constantly sends information about the pressure in the pipes to the logic converter. When the indicator reaches the required level, the control unit pauses the set of engine revolutions, continuing to maintain the set parameters. When the water intake point using the inverter pump is pumping increased volumes of water, the inverter will increase the speed, which will increase the capacity and increase the water pressure in the pipes.

Criterias of choice

As a rule, pump manufacturers indicate in the instructions the options for compatible converters. If there is no instruction, you can choose the correct inverter yourself, focusing on the following parameters:

- power of the electric drive to which the converter will be connected;

- the voltage at the entry point, which determines the inverter's performance - it is necessary to take into account the possibility of voltage surges in the home power grid, since a decrease in it will lead to a device stop, and an increase will lead to a breakdown; the number of phases of the inverter motor is also taken into account;

- levels of fluctuation of control frequencies - in pumping systems intended for use in wells, the correct frequency level of the range is from 200 to 600 Hz;

- the number of input and output control points is proportional to the number of operating modes of the inverter, a large number allows you to perform several operations simultaneously;

- the location of the system control - for pumps working with a well, it is most convenient to control from home.

In the absence of an inverter suitable for all parameters, you need to shorten the search criteria, paying special attention to the main factor - the current that the pump motor consumes, and select the device based on it.

Installation features

- the inverter must be installed in a well-ventilated area;

- the temperature range in the room should be from 10 to 45 degrees and the humidity should be no more than 90%;

- do not allow water to enter the device;

- do not install the converter in places with increased fire hazard;

- exclude the possibility of exposure to direct sunlight;

- install the transducer on a solid, rigid base that is not subject to vibrations;

- Do not install the inverter in an area of electromagnetic radiation.

An important nuance is the ratio of the installation site of the device to a point above sea level. The higher the setting level, the greater the power of the inverter.

Advantages and disadvantages

The connection diagram with a frequency converter has its advantages:

- maintaining constant pressure in the system, regardless of the amount of water consumed;

- protection of the water main from water hammer, as a result, the possible exclusion of the accumulator from the system;

- the use of the converter allows the motor to work in a sparing mode;

- energy savings up to 50%;

- ease of management and ease of use.

The frequency converter works by replacing some of the automatic processes. The cost of the device is high, but the purchase and use costs pay off in a year.

The disadvantages include:

- high cost of the inverter;

- the need to connect and configure with the help of specialists.

Correct use of automation makes it convenient and simple to use a well for industrial and private needs. In order for the pumping equipment to serve for a long time, and the operation was simple, it is necessary to strictly follow the instructions.