Sometimes water disappears in a drilled well. A similar situation may arise for a newly-made owner of a private house or summer cottage. First of all, you need to understand the reasons and try to solve the problem at minimal cost.

Reasons for shallowing a well

The lack of liquid in the intake source or low head can be caused by many factors. The most difficult thing is to rectify the situation if, initially, the place for the hydraulic structure was chosen incorrectly without taking into account the occurrence of underground waters on the territory. If their volume is small, or there is a serious seasonal fluctuation in filling, the well will become shallow.

Other reasons for the loss or lack of water in the well:

- mine pollution;

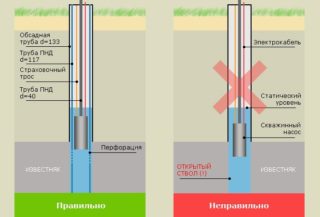

- errors in the installation of the casing;

- infrequent use of water intake;

- simple hydraulic structures in winter;

- incorrect selection of equipment.

Sometimes the reason for the end of the liquid in the well is the drying out of the water vein or the abundance of water intakes in one area.

If the pressure device is not suitable in terms of power and performance, it simply cannot pump the required volume of liquid or create the required pressure. The solution to this problem is simple: replacement of pumping equipment.

It is much more difficult if errors were made during drilling, for example, few flow holes were drilled at the depth of the aquifer or they are not large enough. This makes it difficult for liquids to penetrate into the barrel. We'll have to create a new well or reconstruct an existing one.

If the water flows unevenly, periodically ends, and then flows again, the problem may be in the poor tightness of the main pipeline from the source to the pumping equipment or from the pump to the point of consumption. "Push" water supply can be associated with a breakdown of valves on the main or booster pump, clogged filter or insufficient submersion of the pressure unit.

Ways to solve the problem

Measures are taken depending on the reasons for the lack of water. It is most difficult if the mine was drilled and did not take into account the peculiarities of the groundwater.

Most likely, there will be a need to transfer or deepen it, which costs money.

In order to avoid the same mistake, it is necessary to first conduct a study of the aquifers at the site and determine the most suitable place for a new water intake and its depth.

How to deal with other downhole shallowing problems:

| Cause | Characteristic signs | Solutions |

| Clogging | Small particles of silt and sand close up the bottom and the holes for the inflow of liquid. | Clean with water hammer. The method involves pumping a significant volume of water under pressure into a wellbore shaft. Additionally, chemicals are added to it that destroy solid particles of contaminants. After cleaning, it will take some time to pump out the water to remove impurities. |

| High casing setting | Water accumulates at the bottom, while freely moving through the water layer and does not form a reserve. | Deepen the borehole and install additional pipe segments. |

| Infrequent use of the well | The place where water accumulates is filled with earth. As a result, there is a decrease in the space for the liquid. | Flush the shaft of the hydraulic structure and then use it in a continuous mode.With regular water intake, small particles are quickly washed out and do not cause the bottom level to rise. |

| Using many water points at once | The water flow does not have time to regenerate and fill all shafts or feed all consumers. | Limit the extraction of water from the subsoil or mothball additional mines, if there are any nearby. |

| Drying out the source | The flow of water becomes shallow, the liquid becomes cloudy, thick and oily. | Deepen the shaft with a filter pipe or by undercutting. It is also possible to drill a new source next to the old one, but much deeper. |

If a hydraulic structure created in a sandy soil has become shallow, it is possible to drill an existing well. The reason for the loss of liquid here is the unstable location of the soil, and therefore the bulk of the water mass goes into the adjacent cavities.

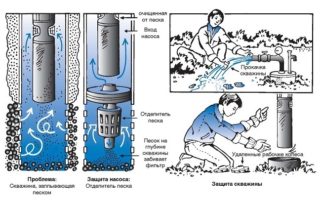

If the water has run out due to the fact that the well is full of dirt and silt, you can pump out the sediment with a bailer. This is a cylindrical metal device with which dirt is scooped out. You can buy it or do it yourself.

Scoop out the dirt with a thief as follows:

- The device is lowered to the bottom of the well on a strong cable.

- Raise it several times by about half a meter and throw it down.

- When the bailer is full of sediment, it is lifted and cleaned.

- The cycle is repeated until complete cleansing.

Next, you need to pump the well with a pump until clean water appears. If after cleaning the flow rate does not increase, you will have to clean or change the filter.

Hydropneumatic flushing is a good way to restore water resources in the shaft of a mine. The method is quite complicated and is performed only by professionals. To work, you will need a powerful pneumatic compressor and a water pump. Impurities are removed by the action of air and water under pressure. In this case, it is necessary to ensure a continuous supply of water flow into the well for flushing.

At home, two pumps are used for these purposes - submersible and surface. The latter will pump a stream of water from a previously prepared container or column, the latter will bring the contaminated liquid to the surface.

Preventive actions

To ensure uninterrupted water supply, all risks must be foreseen at the design stage. Create an exploration well before drilling the main water source. It will show how deep the water layer is and will allow you to evaluate the soil.

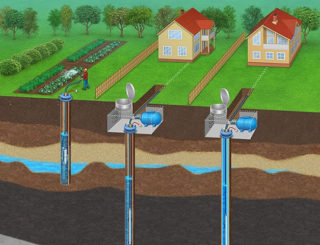

To avoid problems with submersible pressure equipment, it is installed at a depth of 50 cm below the water table and at a distance of more than a meter from the bottom.

Other methods of preventing source shallowing include:

- creation of two parallel columns in sand intakes;

- casing shallow wells with pipes with a cross section of up to 20 cm;

- installation of casing elements below the water level;

- the creation of a large number of perforations;

- the use of filters so that dirt does not clog the perforations;

- regular preventive well pumping.

If seasonal use is expected, it is important to properly preserve the hydraulic structure for the winter. To prevent freezing of the water intake source, it is insulated with thermal insulating materials. The pipe is supplied with a heating wire - this will prevent it from freezing. The pressure device is removed and placed in a warm, dry room. If this is unrealistic, it is also insulated and covered so as to avoid moisture penetration.

If water runs out quickly in a well installation and the hydraulic structure does not provide uninterrupted supply of the house, do not rush to drill a new source. Probably, after the problems are eliminated, the well will serve for a very long time.