Quicksand is an unstable, water-saturated layer of soil, with a thickness varying from one to ten meters. Due to the pressure drop, it begins to move, which leads to the collapse of wells. But with proper drilling, you can painlessly pass a dangerous section.

Quicksand signs

Experts divide unstable layers into real and fake.

The former are distinguished by the following features:

- They contain particles of sand and dust of different sizes. Microscopic fragments act as lubricants, enveloping and binding the entire earthen volume.

- They are rich in clay in the form of a suspension, excessively hydrophobic. Clay components reliably retain moisture. They begin to move under the influence of a water hammer when the quicksand layer is opened.

- They have low filtration properties and high moisture content, which exceeds three percent. Moreover, their moisture content is close to fluidity.

- They swell when freezing and acquire a monolithic hardness when completely dry.

Opinions about the formation of such layers differ, but there is a version that they appear as a result of the activity of microscopic living organisms.

Porous layers, consisting of small particles of sand, are called false. They are oversaturated with water. They lie at a depth of up to 50 m, as a result of which excessive soil pressure acts on them. As a result, small grains of sand were washed into the well shaft.

Fake quicksands give off water well enough, and with a natural or artificial decrease in hydraulic pressure, they pass into a stable state. When drilling, they do not pose a particular danger.

Dangers of Moving Formations

Punching wells through quicksand without preparation can lead to problems:

- filling the annulus of the well with earth that literally floats;

- breakdown of pressure equipment that cannot cope with the increased load;

- loss of a drill string, which is pulled into the cavity that appears after rock washout.

Subsequently, the wellbore may shift, its frequent drying out and the regular ingress of mud particles into the water.

Features of the arrangement of water intake in areas with quicksand

If there is a likelihood of the presence of quicksand, you need to take into account certain nuances of the arrangement of the water intake. Prohibited:

- Install plastic pipes. Over time, the moving formation will crush the polymer element, which will worsen the operation of the system or stop it after the complete destruction of the structure.

- Make an ordinary well. Even if it turns out to reach the required height of the water column in it, then rather quickly the water intake will stop working and supply water to its owners.

- Ignore the annual cleanout of the well, otherwise it will quickly clog up.

Under natural conditions, the liquid layer is in a state of unstable dormancy. But at the beginning of any excavation work, the soil layer, which is excessively saturated with moisture, immediately begins to move, according to its physical properties it becomes like a liquid. All efforts to dig a well in such soil can be compared to attempts to make a depression in the surface of the water, since the liquefied layer will instantly fill the foundation pit.

It is rather difficult to find out exactly whether there is quicksand or not.To find out, it is necessary to carry out exploration work before drilling a mine.

If it is not possible to hire professionals, take a soil sample with a hand drill before punching a mine. Determining the presence of an unstable layer is possible when deepening 1.5–2 m by how the tool will submerge: it will fall as if into a void.

Additionally, you can chat with neighbors who have wells, or see plans of the area created on the basis of engineering and exploration activities. They contain information about the specifics of the soil and the occurrence of aquifers.

Passage of quicksand on shallow water intakes

If a shallow borehole is sufficient - up to 20 m, the unstable layer can be penetrated by traditional percussion drilling. The Abyssinian water intakes are equipped with a similar method. It is not difficult to go through quicksand when percussing a well by hand: all that is required is to hammer the pipe with a heavy metal "woman".

You can use the percussion-rope technique, which involves the use of a bailer placed inside the casing. In such a situation, the device will allow you to pull out the floating soil. To facilitate the work, it is advisable to attach the cable to a special tripod, and to lift it using a gear motor with a clutch.

To prevent the drum from spinning by inertia after hitting the bailer, you can install a special braking device.

If the shaft is shallow and the mud layer itself is close to the surface, another method can be applied. Quicksand is passed here using a hand-assembled tongue-and-groove plank construction. Each element is 5 cm thick and 200 m long, sharpened at the bottom.

To stop the mud flow, you must:

- Drive wood blanks to a depth of 0.4 m along the entire perimeter of the shaft.

- Carefully pick out the soil up to the sharpened bottom of the tongue-and-groove boards and start drilling.

- Repeat the cycle - deepen the sheet pile by driving in and drill again. This must be done until the waterlogged layer is completely passed.

The bottom of the well is reinforced with a simple wooden box with holes. It is placed on a sand-gravel pillow. Thus, a homemade filter from dirt and grains of sand is created. It is also possible to cover the bottom with a board shield, in which holes are drilled for water entry after drilling is completed.

However, such methods of protection against quicksand work only when the water flow with an admixture of mud is not too powerful, flows without pressure.

Problem solving options for deep wells

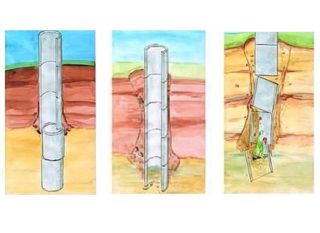

The main task when punching a mine through quicksand is to get through this unstable, moving layer of soil without losing the drill string. To solve the problem, three methods are actively used:

- Parallel casing drilling. The technique consists in the fact that the casing pipe in the process of punching is lowered into the wellbore shaft together with the drill. This significantly delays the entire course of work and makes them more expensive.

- Use of polymer adhesives or bentonite. They are needed to form the walls of the mine, strengthen them and protect them from destruction by quicksand.

- Application of a special conductor. It is intended, as is the case with the casing, to protect the drill rod and the walls of the pierced borehole from the liquefied layer.

The latter option differs from the first in that the conductor is used to drill through an excessively moisture-saturated layer of the earth. Drilling up to the boundary of this formation is carried out in the usual way. Punching a well is also carried out using the traditional method, without the use of a conductor, after full passage of quicksand.

Drilling through an unstable formation is challenging. It is better to choose a place with a more stable subsoil layer or to build an Abyssinian well instead of a conventional well.